ASA (acrylonitrile styrene acrylate) graft copolymerization resin rubber powder and preparation method thereof

A technology of graft copolymerization resin and rubber powder, which is applied in the field of polymer material synthesis, can solve the problems of increasing the dosage of additives and deionized water, reducing the weather resistance of finished ASA, and being unfavorable for blending and modification, and eliminating the need for latex. The effect of particle size enlargement, synthesis route shortening, and good impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Raw material formula: (by weight)

[0035] 5 parts of butyl acrylate, 70 parts of styrene, 25 parts of acrylonitrile, 0.08 parts of initiator (cumene hydroperoxide, sodium persulfate), 0.05 part of emulsifier (sodium dodecylbenzenesulfonate), cross-linked 0.025 part of agent (butylene diacrylate), 0.025 part of functional monomer (methacrylic acid), 0.02 part of chain transfer agent (dodecanethiol), 0.25 part of dispersant (hydroxypropyl cellulose, magnesium sulfate), Activator (sodium bisulfite) 0.01 parts, deionized water H 2 O150 copies.

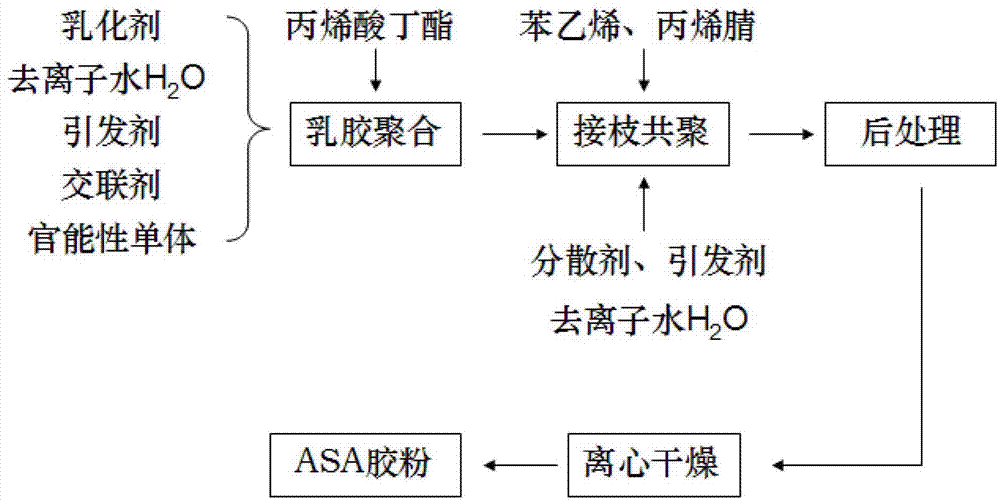

[0036] Preparation process: (such as figure 1 shown)

[0037] First, the deionized water H 2 O is added to the reactor with stirring, start the reactor while stirring, add emulsifier until dissolved, then add initiator, continue stirring, add butyl acrylate, crosslinking agent, functional monomer (including butyl acrylate and cross-linking agent, accounting for 95-99% of all butyl acrylate and cross-linking agent components), ...

Embodiment 2

[0044] Raw material formula: (by weight)

[0045] 30 parts of butyl acrylate, 50 parts of styrene, 20 parts of acrylonitrile, 0.35 parts of initiator (azobisisobutyronitrile, potassium persulfate, sodium persulfate), emulsifier (sodium lauryl sulfate, dodecane Sodium sulfonate) 0.5 part, crosslinking agent (butylene diacrylate) 0.15 part, functional monomer (propyl methacrylate, ethylene glycol acrylate) 0.15 part, dispersant (methyl cellulose, poly Vinyl alcohol, magnesium carbonate) 0.5 part, activator (sodium bisulfite) 0.05 part, chain transfer agent (dodecanethiol) 0.002 part, deionized water H 2 O500 copies.

[0046] Preparation process: the same as the preparation method described in Example 1 to obtain fine granular ASA resin powder with a particle size of 20-120 mesh.

[0047] Material properties:

[0048] The ASA resin obtained by the above preparation method has good toughness, good processability, high elongation at break, good ductility, and good weather resist...

Embodiment 3

[0050] Raw material formula: (by weight)

[0051] 20 parts of butyl acrylate, 60 parts of styrene, 20 parts of acrylonitrile, 0.25 parts of initiator (tert-butyl peroxybenzoate, hydrogen peroxide), 0.3 parts of emulsifier (sodium dodecylsulfonate), crosslinking agent ( Butylenediacrylate diacrylate) 0.10 part, functional monomer (propyl methacrylate) 0.12 part, chain transfer agent (dodecyl mercaptan) 0.01 part, dispersant (hydroxyethyl cellulose, diatomaceous earth) 0.3 part , 0.03 parts of activator (sodium sulfoxylate), 350 parts of deionized water H2O.

[0052] Preparation process: the same as the preparation method described in Example 1 to obtain fine granular ASA resin powder with a particle size of 20-120 mesh.

[0053] Material properties:

[0054] The ASA resin obtained by the above preparation method has good comprehensive performance and wide application range, and can be used to prepare various outdoor plastic products. The performance data are tested as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com