Catalyst for preparing cyclohexanol through cyclohexene hydration and application of catalyst

A cyclohexene hydration and catalyst technology, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, hydroxyl addition preparation, etc., can solve the problems of short life of ion exchange resins, equipment corrosion, poor thermal stability, etc., and achieve easy regeneration and Effects of repeated use, reduction of mass transfer resistance, and improvement of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 50 grams of Nb prepared in Comparative Example 1 2 o 5 Load HZSM-5 catalyst, put into 300 ml of trimethylchlorosilane-toluene solution with a concentration of 0.1 g / ml, stir at room temperature for 3 hours, filter with sand core funnel, and use 100 ml of carbon tetrachloride and 100 ml of Wash with ethanol three times each, and finally dry at 50 °C for 5 hours to obtain the loaded Nb 2 o 5 The amphiphilic HZSM-5 catalyst is denoted as TMCS-Nb / HZSM-5.

Embodiment 2~11

[0028] The same preparation method as in Example 6, except that the silylating agent is changed to hexamethyldisilazane (HMDSZ), triethylchlorosilane (TECS), triisopropylchlorosilane (TIPCS), cyclohexyltrichlorosilane (CHTCS), dimethylvinylchlorosilane (DMVCS), dimethylisopropylchlorosilane (TMCS), tert-butyldimethylchlorosilane (TBDMCS), dimethyloctylchlorosilane (DMOCS), Octadecyltrichlorosilane (OTCS), n-octyltrichloroazane, etc. (OTCSZ). Prepared loaded Nb 2 o 5 The amphiphilic HZSM-5 catalysts are denoted as HMDSZ-Nb / HZSM-5, TECS-Nb / HZSM-5, TIPCS-Nb / HZSM-5, CHTCS-Nb / HZSM-5, DMVCS-Nb / HZSM-5, respectively 5. TMCS-Nb / HZSM-5, TBDMCS-Nb / HZSM-5, DMOCS-Nb / HZSM-5, OTCS-Nb / HZSM-5 and OTCSZ-Nb / HZSM-5.

Embodiment 12

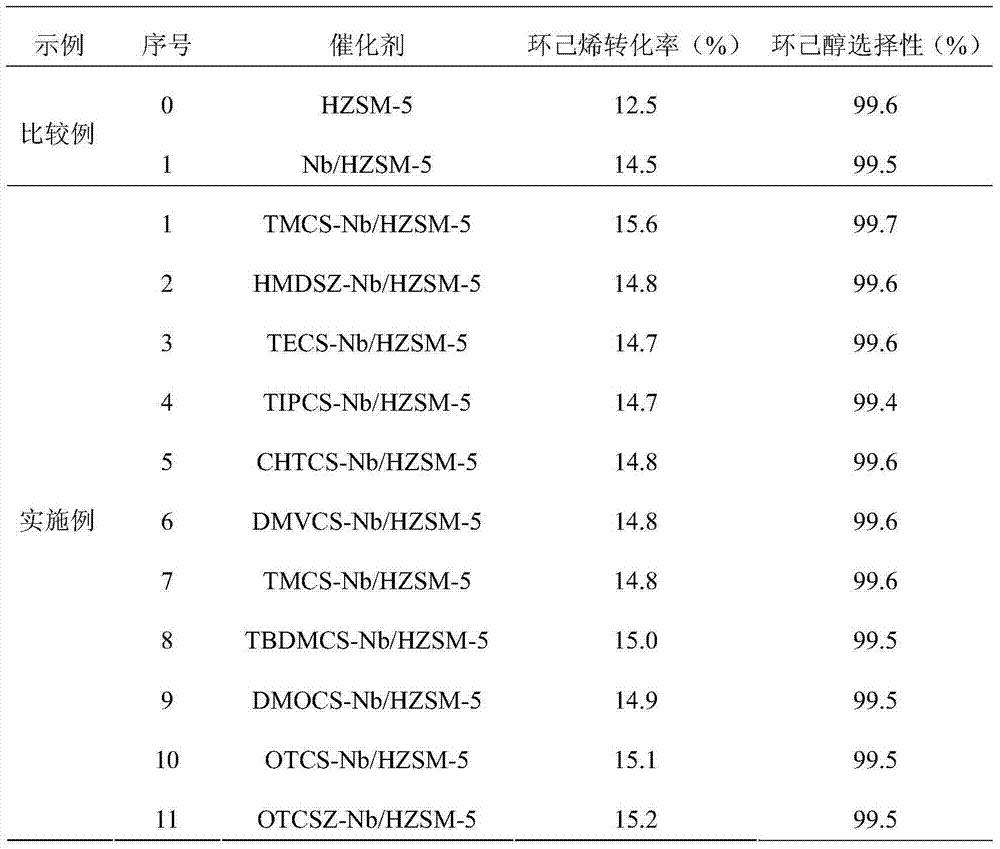

[0030] The amphiphilic supported niobium HZSM-5 catalysts prepared in Examples 1-11 were applied to the reaction of cyclohexene hydration to prepare cyclohexanol, and the reaction results were compared to evaluate the performance of the catalysts prepared in each example. The evaluation method was the same as in Comparative Example 1. The activity evaluation results of the catalysts prepared in Examples 1-11 are shown in Table 1.

[0031] Table 1 Effects of catalysts modified with different silylating agents on the hydration reaction

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com