Method for extracting and purifying human relaxin-2 from fermentation liquor

A technology of relaxin and fermentation liquid, which is applied in the field of extraction and purification of polypeptide drugs, can solve the problems of complex process steps, long time consumption, and inability to meet large-scale industrial production, and achieve simplified process steps, easy control of process conditions, and shortened extraction and purification time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

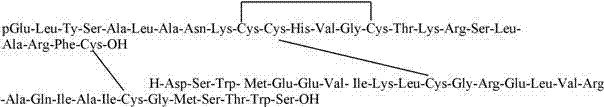

Image

Examples

Embodiment 1

[0020] Example 1 Extraction and Purification of Human Relaxin-2 from Fermentation Broth

[0021] 1) Take the fermentation broth, centrifuge at 6000rmp for 15 minutes, and collect the supernatant;

[0022] 2) Add 4 times the volume of 70% acetone to the supernatant in step 1), adjust the pH to 5.0 with acetic acid-sodium acetate buffer solution, add urea to make the concentration of urea in the solution 7mol / L, and let stand at 5°C overnight;

[0023] 3) Centrifuge the solution in step 2) at 14000rmp for 30 minutes, pass through a cellulose acetate ultrafiltration membrane with a molecular weight cut-off of 3000, and collect the concentrated solution;

[0024] 4) Put the concentrated solution of step 3) on a SephadexG-50 column, the column length is 22 cm, the elution solvent is 1 mol / L acetic acid containing 0.15 mol / L sodium chloride, the flow rate is 15 mL / hour, collect the eluate, and vacuum low temperature concentrate;

[0025] 5) The concentrated solution of step 4) is...

Embodiment 2

[0028] Example 2 Extraction and Purification of Human Relaxin-2 from Fermentation Broth

[0029] 1) Take the fermentation broth, centrifuge at 6500rmp for 45 minutes, and collect the supernatant;

[0030] 2) Add 4 times the volume of 70% acetone to the supernatant in step 1), adjust the pH to 5.0 with acetic acid-sodium acetate buffer solution, add urea to make the concentration of urea in the solution 5mol / L, and let stand at 7°C overnight;

[0031] 3) Centrifuge the solution in step 2) at 15000rmp for 20 minutes, pass through a cellulose acetate ultrafiltration membrane with a molecular weight cut-off of 3000, and collect the concentrated solution;

[0032] 4) Put the concentrated solution of step 3) on a SephadexG-50 column, the column length is 22 cm, the elution solvent is 1 mol / L acetic acid containing 0.15 mol / L sodium chloride, the flow rate is 15 mL / hour, collect the eluate, and vacuum low temperature concentrate;

[0033] 5) The concentrated solution of step 4) is...

Embodiment 3

[0036] Example 3 Extraction and Purification of Human Relaxin-2 from Fermentation Broth

[0037] 1) Take the fermentation broth, centrifuge at 5500rmp for 45 minutes, and collect the supernatant;

[0038] 2) Add 4 times the volume of 70% acetone to the supernatant in step 1), adjust the pH to 5.0 with acetic acid-sodium acetate buffer solution, add urea to make the concentration of urea in the solution 12mol / L, and let stand at 3°C overnight;

[0039] 3) Centrifuge the solution in step 2) at 15000rmp for 50 minutes, pass through a cellulose acetate ultrafiltration membrane with a molecular weight cut-off of 3000, and collect the concentrated solution;

[0040] 4) Put the concentrated solution of step 3) on a SephadexG-50 column, the column length is 22 cm, the elution solvent is 1 mol / L acetic acid containing 0.15 mol / L sodium chloride, the flow rate is 15 mL / hour, collect the eluate, and vacuum low temperature concentrate;

[0041] 5) The concentrated solution of step 4) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com