Method for preparing pucherite-graphene composite photocatalyst

A graphene composite and photocatalyst technology, which is applied in the field of photocatalytic degradation of organic pollutants, can solve problems such as the inability to ensure the tight connection between bismuth vanadate and graphene, limited improvement in photocatalytic performance, and difficulty in separating photogenerated carriers. Improve photocatalytic performance, facilitate transportation, and have strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

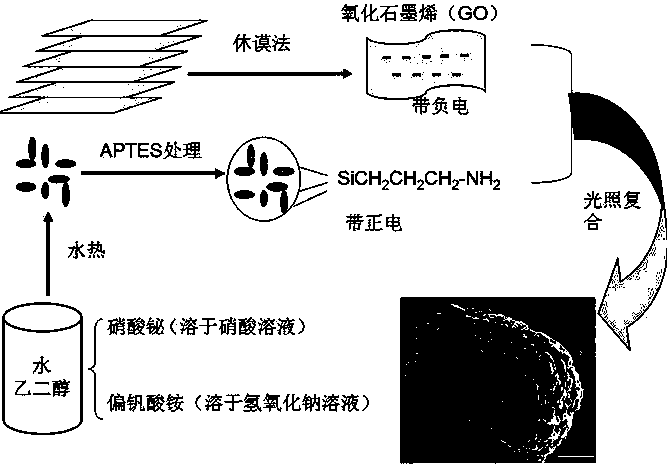

[0025] combine figure 1 , the preparation method concrete steps of acid bismuth-graphene composite photocatalyst among the present invention are as follows:

[0026] 1) Preparation of uniform porous olive-shaped bismuth vanadate powder: Bismuth nitrate and ammonium metavanadate are used as raw materials, and a mixture of water and ethylene glycol with a volume ratio of 2:1 is used as a solvent, prepared by an organic solvent-hydrothermal method Uniformly dispersed porous olive-like bismuth vanadate powder;

[0027] 2) Prepare graphene oxide colloidal suspension: use graphite powder as raw material, prepare graphene oxide by Hume method, wash graphene oxide with water, dry after alcohol washing, and disperse it in ethanol solution after grinding;

[0028] 3) Pretreatment of bismuth vanadate powder: ultrasonically disperse bismuth vanadate powder annealed at 300-500 °C in absolute ethanol, add silane coupling agent, and continue stirring at room temperature. Finally, the treate...

Embodiment 1

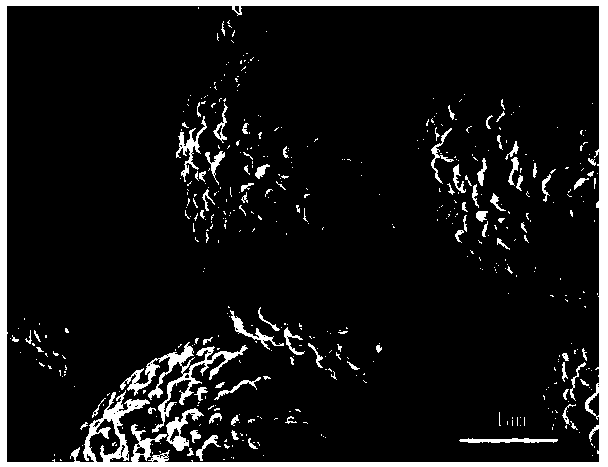

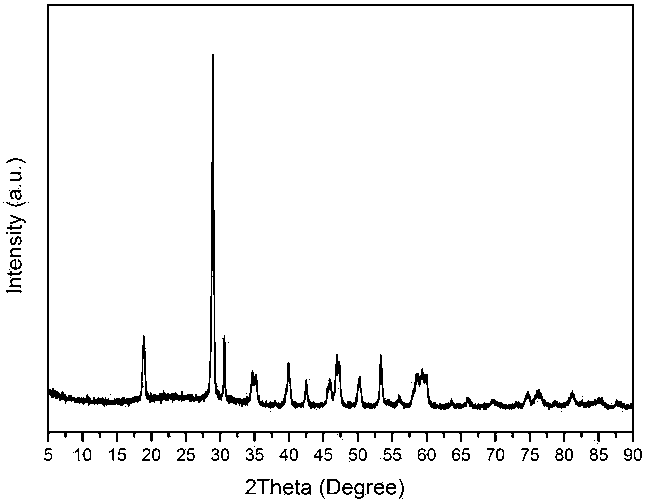

[0032] Step 1: 1) 1.458 g (3 mmol) Bi(NO 3 ) 3 ·5H 2 O and 0.351 g (3 mmol) NH 4 VO 3 respectively dissolved in 4 mol / L HNO 3 solution (50 mL) and 2 mol / L NaOH solution (50 mL); 2) Add 25 mL of ethylene glycol to each of the above two solutions, stir well, and add NH 4 VO 3 The solution was slowly added dropwise to the Bi(NO 3 ) 3 3) adjust the pH to 1, transfer it to a polytetrafluoroethylene hydrothermal kettle after fully stirring, and conduct a hydrothermal reaction at 180 °C for 12 hours. The final precipitate is washed with water and alcohol, and then dried. figure 2 The SEM shows that the bismuth vanadate particles have a regular shape, a porous structure, and a particle size of 2-3 um; image 3 The XRD pattern of the machine shows that the bismuth vanadate prepared by the machine is a monoclinic scheelite phase with high crystallinity and the highest catalytic activity, corresponding to the standard card (JCPDS NO.83-1699).

[0033] The second step: 1) Use gr...

Embodiment 2

[0037] Step 1: 1) 1.458 g (3 mmol) Bi(NO 3 ) 3·5H 2 O and 0.351 g (3 mmol) NH 4 VO 3 respectively dissolved in 4 mol / L HNO 3 solution (50 mL) and 2 mol / L NaOH solution (50 mL); 2) Add 25 mL of ethylene glycol to each of the above two solutions, stir well, and add NH 4 VO 3 The solution was slowly added dropwise to the Bi(NO 3 ) 3 3) adjust the pH to 1, transfer it to a polytetrafluoroethylene hydrothermal kettle after fully stirring, and conduct a hydrothermal reaction at 160 °C for 12 hours. The final precipitate is washed with water and alcohol, and then dried.

[0038] The second step: 1) Use graphene as raw material to prepare graphene oxide by the Hume method; 2) Grind the graphene after pickling, alcohol washing and drying, and disperse it in absolute ethanol to obtain the concentration 0.1 mg / mL.

[0039] The third step: 1) Anneal the bismuth vanadate powder obtained in the first step at 300 °C in the atmosphere for 3 hours; 2) Disperse 0.5 g of the annealed bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com