Grinding composition used for gallium nitride material, and its preparation method

A composition, gallium nitride technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as new products, provide technical support, etc., achieve high-efficiency grinding effect, excellent surface smoothness, and good industrial application prospects and market value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

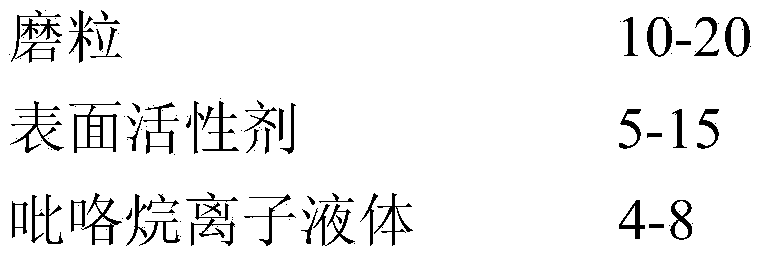

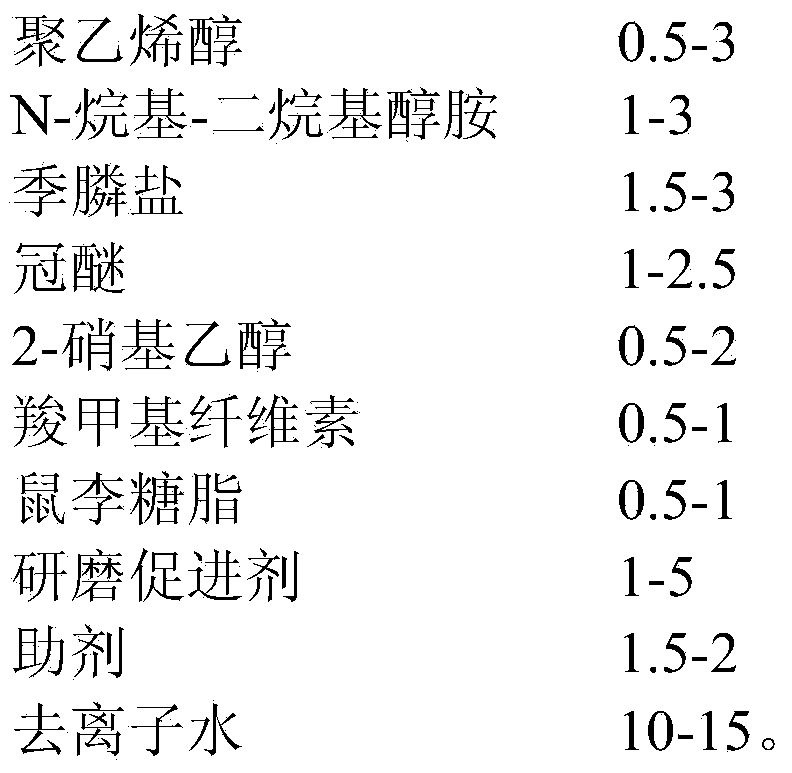

Method used

Image

Examples

Embodiment 1

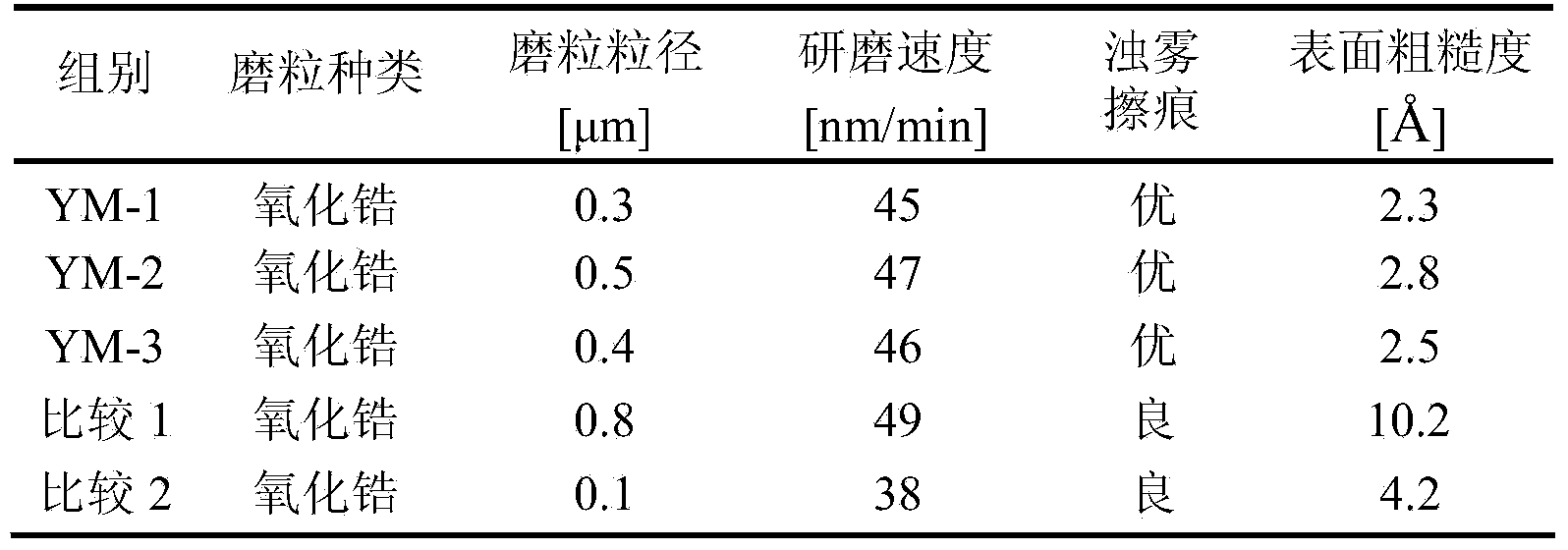

[0039] According to the weight ratio, 120g of zirconia abrasive grains (with a particle size of 0.3 μm), 100g of [N-(4-perfluoro-(1,3-dimethyl-2-isopropyl)-1-butenyloxy ) benzenesulfonylamino]ethyldiethylmethylammonium iodide, 40g 1-butyl-1-methylpyrrolidine tetrafluoroborate, 20g polyvinyl alcohol, 10g N-methyldiisopropanolamine, 15g Tetrabutylphosphine bromide, 25g of dibenzo-14-crown-4, 5g of 2-nitroethanol, 8g of carboxymethyl cellulose, and 5g of rhamnolipid were added to the mixing kettle and heated to 40°C, stirred for 15min; Cool to room temperature, add 20 g of glycine, 15 g of pentaerythritol triacrylate and 100 g of deionized water to the above mixed solution according to the weight ratio in turn and continue to stir for 10 min to uniformly disperse to obtain the grinding composition YM-1 of the present invention. .

Embodiment 2

[0041] According to the weight ratio, 150g of zirconia abrasive grains (particle size is 0.5μm), 120g of 2-[N-methyl-[perfluoro-2-[2-(propoxy)-propoxy]propionylamino]- Sodium ethyl sulfate, 80g 1-butyl-1-methylpyrrolidine bromide, 10g polyvinyl alcohol, 30g N-ethyldiisopropanolamine, 20g tetrabutylphosphine chloride, 10g dibenzo-14 - Crown-4, 10g 2-nitroethanol, 5g carboxymethyl cellulose, 10g rhamnolipid were added in the mixing kettle and heated to 35°C, stirred for 20min; then naturally cooled to room temperature, 30g alanine, 18g ethylenedi The alcohol diacrylate and 120 g of deionized water were sequentially added to the above mixed solution according to the weight ratio and continued to stir for 5 min, and then dispersed evenly to obtain the grinding composition YM-2 of the present invention.

Embodiment 3

[0043] According to the weight ratio, 180g of zirconia abrasive grains (particle size is 0.4μm), 80g of [N-[4-[perfluoro-(1,3-dimethyl-2-isopropyl)-1-butene] Oxybenzenesulfonamido] ethyldiethylmethylammonium iodide, 60g 1-butyl-1-methylpyrrolidine nitrate, 15g polyvinyl alcohol, 20g N-propyl diisopropanolamine, 30g tetramine Butyl phosphine acetate, 15g dibenzo-14-crown-4, 20g 2-nitroethanol, 10g carboxymethyl cellulose, 8g rhamnolipid were added to the mixing kettle and heated to 45°C, stirred for 18min; then cooled naturally to At room temperature, 40g of tryptophan, 20g of pentaerythritol triacrylate and 150g of deionized water were sequentially added to the above mixed solution according to the weight ratio and continued to stir for 8min, and uniformly dispersed to obtain the grinding composition YM-3 of the present invention. . Comparative Examples 1-3

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com