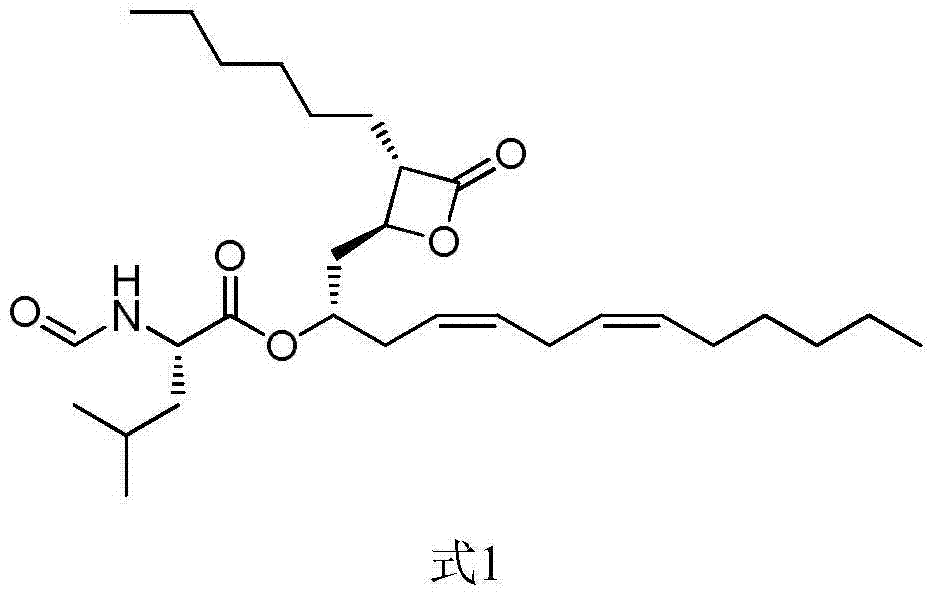

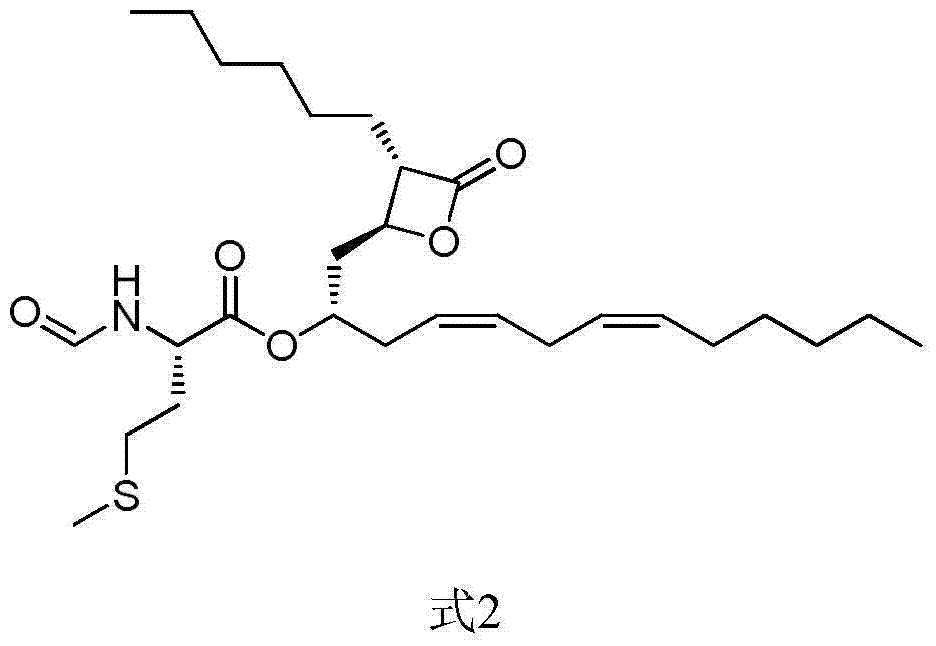

Method for fermentation production of lipstatin

A technology of liprex and statin, which is applied in the field of fermentative production of liprestatin, can solve the problems of reduced output of metabolites, shortened product synthesis stages, and consumption, and achieves the effects of reducing fermentation costs and increasing fermentation titer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]Slant culture: Prepare medium according to the following ratio: glucose 2g / L, malt extract 8g / L, yeast extract 10g / L, agar 15g / L, pH 7.1. Prepare 300 mL of culture medium, heat the agar to melt, stir evenly, put it into 10 large test tubes, sterilize, and make it into a slope for later use. Dissolve the freeze-dried Streptomyces toxin strains in 5 mL of sterile water, take 4 mL and evenly spread them on 10 inclined surfaces at a temperature of 28°C and a humidity of 40%, and cultivate them for 10 days to produce a large number of spores. spore suspension.

[0025] Shake flask seed solution preparation: Prepare medium according to the following ratio: glycerol 10g / L, malt extract 10g / L, yeast extract 5g / L, defatted soybean powder 20g / L, pH 6.0. Prepare 200mL of culture medium, put it into 4 bottles of 500mL Erlenmeyer flasks (each bottle contains 50mL), sterilize and set aside. Inoculate 2 mL of the spore suspension into the shake flask. The temperature was 28° C. and ...

Embodiment 2

[0029] With reference to Example 1, the slant culture was carried out, the shake flask seed solution was prepared, and the seed tank was cultivated. Fermentation tank culture: a 50L fermenter was used for cultivation. Among them, the liquid medium was prepared according to the following proportions: glycerin 10g / L, defatted soybean powder 20g / L, soybean oil 10g / L, antifoaming agent 2g / L, pH 7.0. The volume after elimination is 33.25L. When the temperature drops to 28°C, the cultured seed tank bacteria are inoculated into the fermenter with an inoculum size of 5% (1.75L). Under the condition of 28°C, the whole process Control the dissolved oxygen at 40% by adjusting tank pressure, rotation speed and ventilation. The stirring speed is 300-540 rpm, the ventilation rate is 0.6VVM-1.1VVM (volume / volume / minute), and the tank pressure is 0.06-0.08MP. From 29 hours after fermentation and inoculation, the dissolved oxygen rose sharply to 70%, and immediately began to feed the mixed f...

Embodiment 3

[0031] With reference to Example 1, the slant culture was carried out, the shake flask seed solution was prepared, and the seed tank was cultivated. Fermentation tank culture: 500L fermentation tank was used for cultivation. Among them, the liquid medium was prepared according to the following proportions: glycerol 10g / L, defatted soybean powder 20g / L, soybean oil 10g / L, defoamer 2g / L, pH 7.0. The volume after elimination is 335L. When the temperature drops to 28°C, the cultured seed tank bacteria are inoculated into the fermenter with an inoculum size of 5% (16.7L). Under the condition of 28°C, the whole process Control the dissolved oxygen at 40% by adjusting the tank pressure, rotation speed and ventilation. The stirring speed is 300-540 rpm, the ventilation rate is 0.6VVM-1.1VVM (volume / volume / minute), and the tank pressure is 0.06-0.08MP. From 30 hours after fermentation and inoculation, the dissolved oxygen increased sharply to 70%, and immediately began to feed the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com