Method for preparing conjugated polymer nano material

A technology of conjugated polymers and nanomaterials, applied in the field of nanomaterials and organic synthesis, can solve the problems of difficult to control the morphology and size of polymer nanomaterials, uncontrollable morphology and size of polymer nanomaterials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

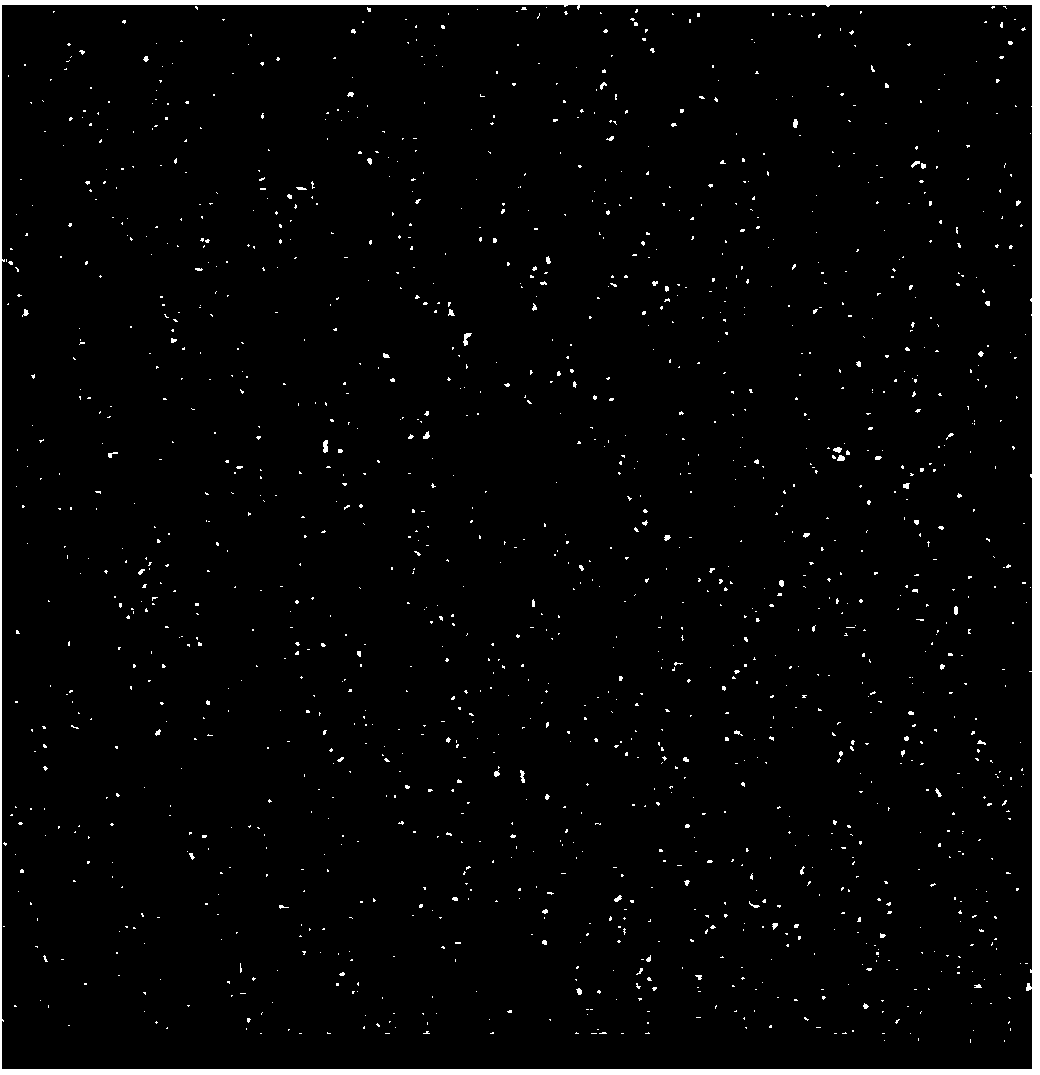

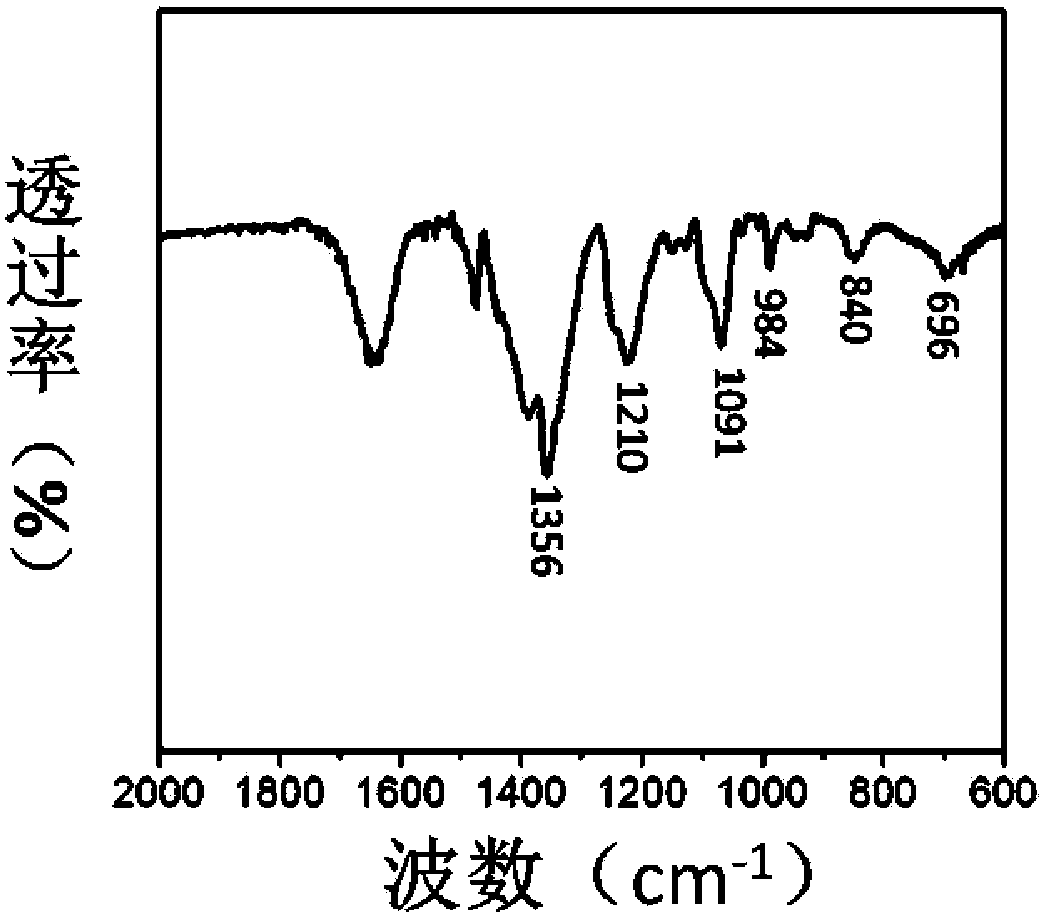

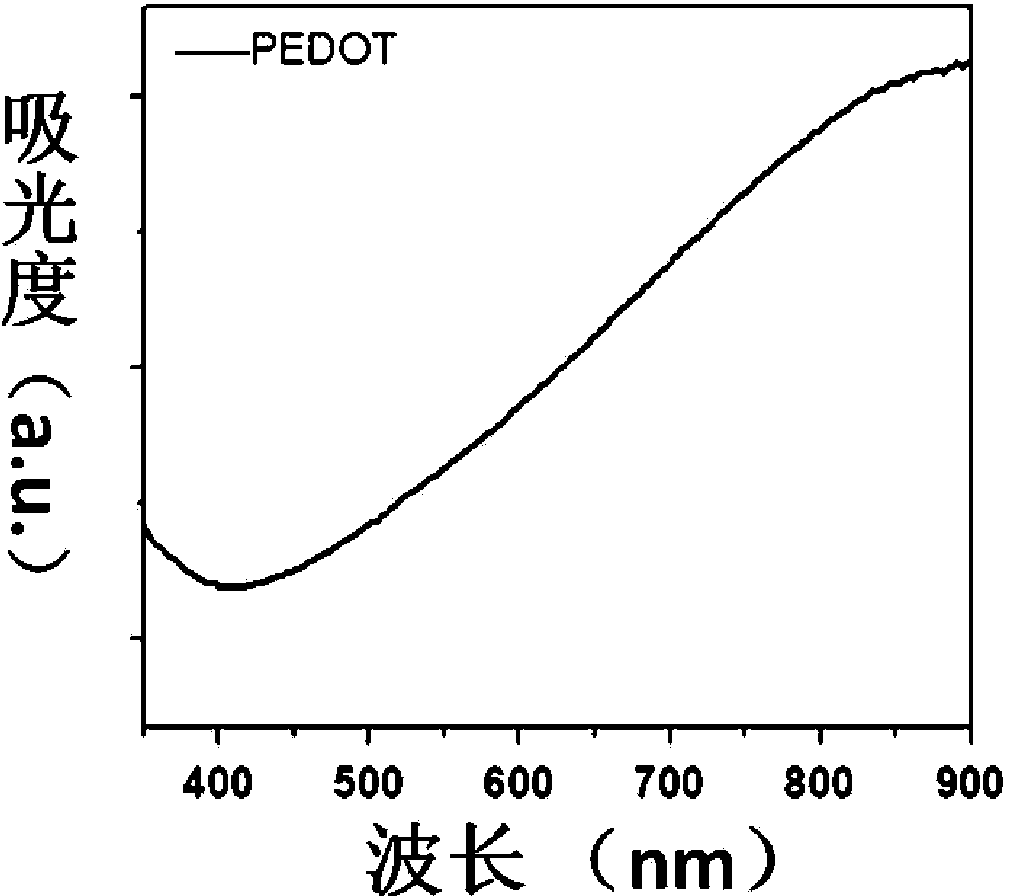

[0034] Example 1. Hydrothermal synthesis of poly-3,4-ethylenedioxythiophene (PEDOT) nanoparticles

[0035] 0.71 g (2.04 mmol) SDBS, 10 mL water, 10 mL methanol, and 10 mL sulfuric acid (0.2 M) were mixed together and stirred to give a microemulsion. EDOT (50 μL, 0.47 mmol) monomer was added to the solution, ultrasonically dispersed for 10 minutes, stirred for 20 minutes, and then added with equimolar FeCl to EDOT monomer. 3 ·6H 2 O was dissolved in an aqueous solution of water and stirred for 2 hours. The mixed solution was transferred to a 50 mL hydrothermal kettle, and hydrothermally treated at 140° C. for 5 hours. After natural cooling, the nanoparticles were separated by centrifugation, washed three times with methanol, and dried. The PEDOT nanoparticles can be obtained with a particle size of 15-20 nm. These nanoparticles can be well dispersed in methanol.

[0036] figure 1 is the transmission electron microscope picture of the prepared PEDOT nanoparticles.

[0037...

Embodiment 2

[0042] Example 2. Hydrothermal synthesis of polypyridine (PPy) nanoparticles

[0043] 1.5 g (4.08 mmol) SDBS, 10 mL water were mixed together and stirred to obtain a microemulsion. Py (100 μL, 1.44 mmol) monomer was added to the solution, ultrasonically dispersed for 10 minutes, stirred for 20 minutes, and then added with equimolar FeCl to the pyrrole monomer. 3 ·6H 2 O was dissolved in an aqueous solution of water and stirred for 2 hours. The mixed solution was transferred to a 50 mL hydrothermal kettle, and hydrothermally treated at 140° C. for 5 hours. After natural cooling, the nanomaterials were separated by centrifugation, washed three times with ethanol, and dried. The PPy nanoparticles can be obtained with a particle size of 20-30 nm. These nanoparticles can be well dispersed in ethanol.

[0044] Figure 4 is the transmission electron microscope picture of the prepared PPy nanoparticles.

[0045] Figure 5 is the UV spectrum of the as-prepared PPy nanoparticles...

Embodiment 3

[0048] Example 3. Hydrothermal synthesis of polyaniline (PANI) nanoparticles

[0049]0.71 g (2.04 mmol) of SDS, 10 mL of water, 10 mL of methanol and 8 mL of sulfuric acid (0.2 M) were mixed together and stirred to obtain a microemulsion. Add ANI (50μL, 0.55mmol) monomer to this solution, ultrasonically disperse for 10 minutes, stir for 20 minutes, then add (NH 4 ) 2 S 2 O 8 Dissolve in water to form an aqueous solution and stir for 2 hours. The mixed solution was transferred to a 50 mL hydrothermal kettle, and hydrothermally treated at 140° C. for 5 hours. After natural cooling, the nanomaterials were separated by centrifugation, washed three times with methanol, and dried. The PANI nanoparticles can be obtained, and the particle diameter is 10-25nm. These nanoparticles can be well dispersed in methanol.

[0050] Image 6 is a transmission electron micrograph of the prepared PANI nanoparticles.

[0051] Depend on Image 6 It can be seen that the particle size of PAN...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com