Flexible titanium oxide nanofiber membrane and preparation method thereof

A technology of nanofiber membrane and titanium oxide, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of single fiber defects, poor diameter uniformity, and easy fiber cracking, etc., and achieve simple preparation process, Good flexibility and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

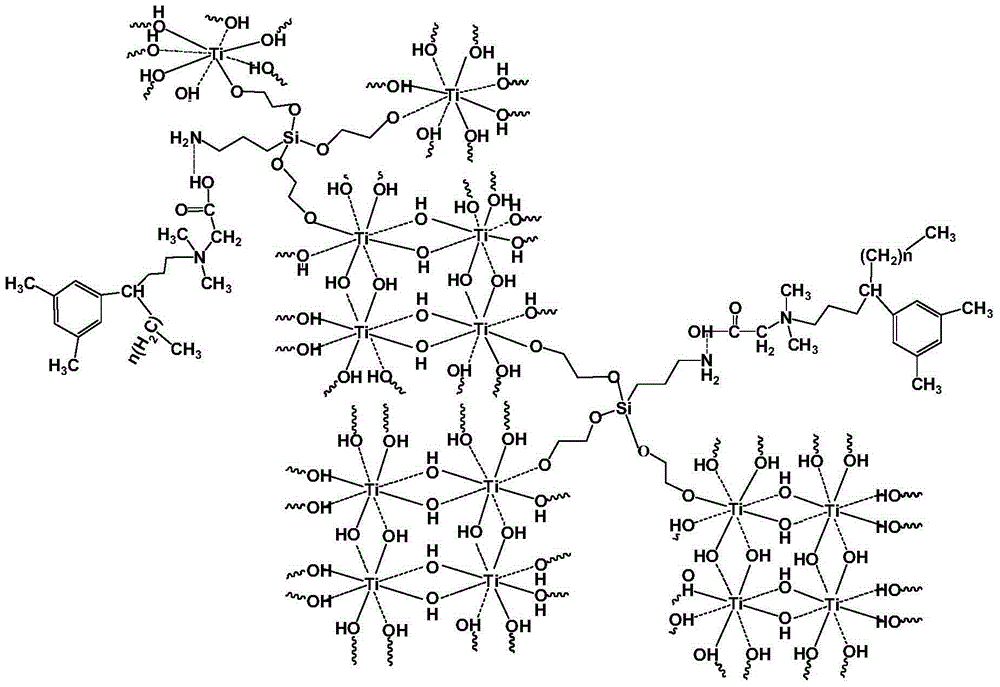

Method used

Image

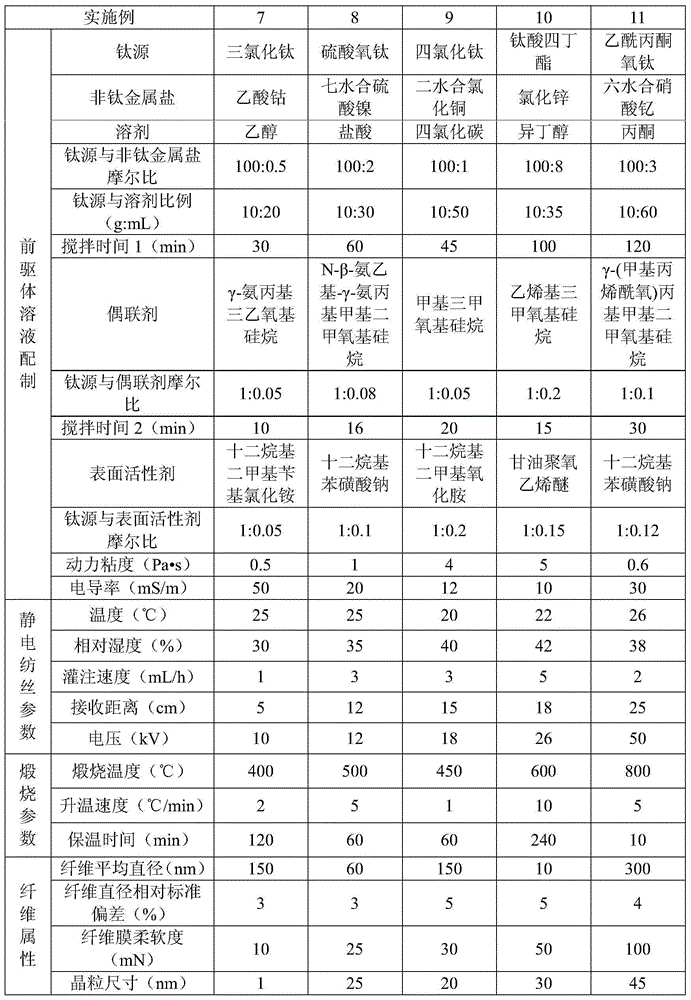

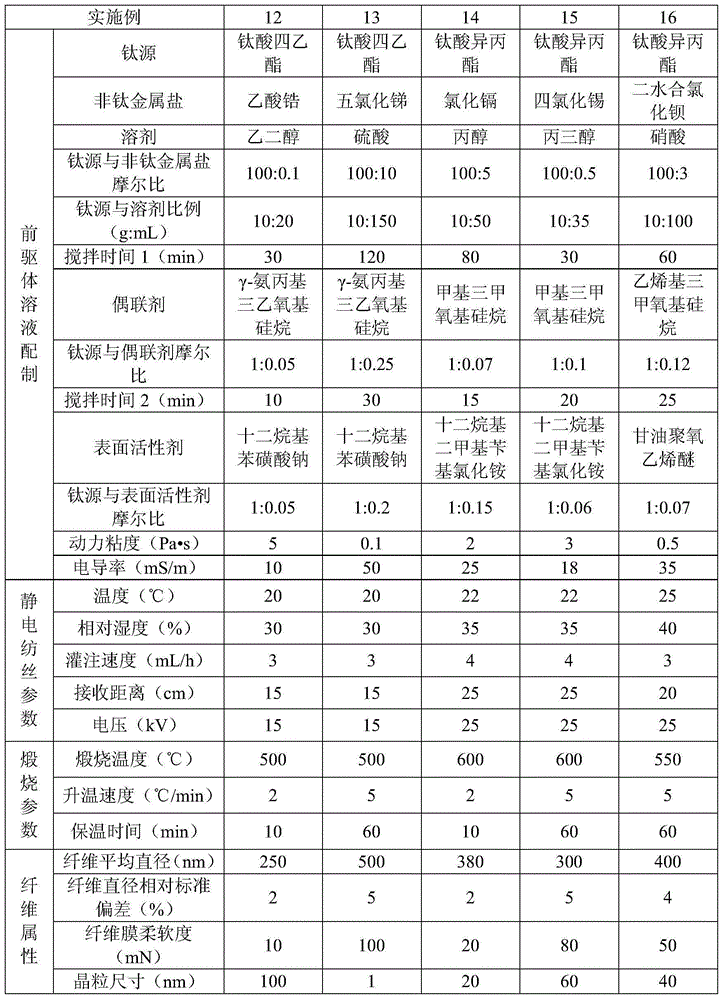

Examples

Embodiment 1

[0048] A method for preparing a flexible titanium oxide nanofiber membrane, the specific steps are:

[0049] Step 1: Dissolve titanium source tetraethyl titanate and non-titanium metal salt magnesium chloride hexahydrate in sequence in a mixed solvent of ethanol / acetic acid, stir for 30 minutes, add coupling agent γ-aminopropyltriethoxysilane, and then Add surfactant dodecyl dimethyl benzyl ammonium chloride after continuous stirring for 10 min, wherein the molar ratio of tetraethyl titanate to magnesium chloride hexahydrate is 100:0.1, and the ratio of tetraethyl titanate to ethanol / acetic acid is 10g:20mL, the volume ratio of ethanol to acetic acid is 1:1, the molar ratio of tetraethyl titanate to coupling agent γ-aminopropyltriethoxysilane is 1:0.05, tetraethyl titanate and surface active The molar ratio of dodecyl dimethyl benzyl ammonium chloride is 1:0.05; uniform and stable kinematic viscosity is mixed to make a precursor solution of 0.1Pa·s and electrical conductivity ...

Embodiment 2

[0054] A method for preparing a flexible titanium oxide nanofiber membrane, the specific steps are:

[0055] Step 1: Dissolve titanium source isopropyl titanate and non-titanium metal salt aluminum nitrate nonahydrate in a mixed solvent of ethanol / hydrochloric acid in sequence, stir for 60 minutes and add coupling agent N-β-aminoethyl-γ-ammonia Propylmethyldimethoxysilane, continue to stir for 15min, then add surfactant sodium dodecylbenzenesulfonate, wherein the molar ratio of isopropyl titanate to aluminum nitrate nonahydrate is 100:1, and isopropyl titanate The ratio of ester to ethanol / hydrochloric acid is 10g:20mL, the volume ratio of ethanol to hydrochloric acid is 1:2, isopropyl titanate and coupling agent N-β-aminoethyl-γ-aminopropylmethyldimethoxy The molar ratio of base silane is 1:0.25, and the molar ratio of isopropyl titanate to surfactant sodium dodecylbenzenesulfonate is 1:0.05; mix uniformly to make a uniform and stable dynamic viscosity of 1Pa s, conductivity ...

Embodiment 3

[0059] A method for preparing a flexible titanium oxide nanofiber membrane, the specific steps are:

[0060] The first step: dissolve the titanium source tetraethyl titanate and the non-titanium metal salt calcium chloride in the mixed solvent of ethanol / acetic acid / N,N-dimethylformamide in turn, stir for 120min, and then add the coupling agent methyl Trimethoxysilane, after continuing to stir for 30min, add the surfactant dodecyl dimethyl amine oxide, wherein the molar ratio of tetraethyl titanate to calcium chloride is 100:10, tetraethyl titanate and ethanol / acetic acid The ratio of / N,N-dimethylformamide is 10g:30mL, the volume ratio of ethanol, acetic acid, N,N-dimethylformamide is 1:1:1, tetraethyl titanate and coupling agent A The molar ratio of trimethoxysilane is 1:0.25, and the molar ratio of tetraethyl titanate and surfactant lauryl dimethyl amine oxide is 1:0.2; mix well to make a uniform and stable dynamic viscosity of 5Pa s, a precursor solution with a conductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com