In-vivo degradable and absorbable artificial medical tissue repairing film

A tissue repair and artificial technology, applied in the direction of prosthesis, medical science, etc., can solve the problems of unfavorable tissue repair, unfavorable tissue repair and application, easy swelling of silicone rubber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

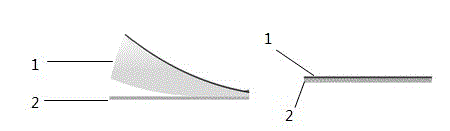

Image

Examples

Embodiment 1

[0037] Example 1 Dissolve copolyglycolide / lactide (PLGA) with a molecular weight of 50,000 in chloroform to make a 5% solution, then add porogen sodium chloride with the same weight as PLGA, stir well and inject polytetrafluoroethylene For vinyl molds, first volatilize the solvent at normal temperature and pressure, and then soak in distilled water to dissolve the porogen after the solvent volatilizes into a hard solid; change the soaking solution several times until no chloride ions are detected. The sponge from which the porogen was removed was dried at room temperature under vacuum for 1-3 days to remove moisture, and a sponge-like porous structure layer with a thickness of 1.0 mm was obtained. After the porous structure layer was treated with oxygen plasma, it was immersed in an aqueous solution of penicillin for 1 hour, taken out, frozen at -20°C, and then dried in a freeze dryer for 48 hours to load penicillin. Dissolve poly-L-lactic acid (PLLA) with a molecular we...

Embodiment 2

[0038] Example 2 Dissolve polycaprolactone / polyethylene glycol block copolymer (PCE) with a polyethylene glycol block molecular weight of 2000 and a molecular weight of 80,000 in dioxane to make a 10% solution; then add 5-Fluorouracil with an amount of 0.01% of the mass of PCE is stirred evenly and poured into a polytetrafluoroethylene mold, freeze-shaped at -20°C, freeze-dried in a freeze dryer for 48 hours, and then vacuum-dried at room temperature for 48 hours to obtain a thickness A 2.0mm artificial tissue repair membrane porous structure layer. After the porous structure layer was treated with plasma oxygen plasma, soaked in erythromycin ethanol solution for 1 hour, the porous structure layer was taken out, frozen at -20°C, and dried in a freeze dryer for 48 hours to load penicillin. Dissolve copoly(lactide / caprolactone) (PLC) with a molecular weight of 150,000 in chloroform to make a 10% solution, scrape the film on a polytetrafluoroethylene plate, and evaporate th...

Embodiment 3

[0039] Example 3 Dissolve polycaprolactone / polyethylene glycol block copolymer (PCE) with a polyethylene glycol block molecular weight of 4000 and a molecular weight of 80,000 in chloroform to prepare a 3% solution, which is prepared by electrospraying 0.2mm thick porous structure layer. After treating the porous structure layer with plasma oxygen plasma, soak it in the aqueous solution of growth factor BMP for 1 hour, take out the porous structure layer, freeze at -20°C, and dry it in a freeze dryer for 48 hours to obtain a BMP load of PCE One ten thousandth of the porous structure layer. Dissolve poly DL-lactic acid (PDLLA) with a molecular weight of 200,000 in acetone to make a 10% solution, scrape the film on a polytetrafluoroethylene plate, volatilize the solvent at room temperature and pressure to form a film, and then dry it in vacuum at room temperature 1-3 days to ensure that the solvent is completely removed to obtain a dense structure layer with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com