A kind of preparation method of praseodymium yellow pigment

A pigment, the technology of praseodymium yellow, which is applied in the field of preparation of praseodymium yellow pigment, can solve the problems of easy harm to human body and natural environment safety, large pigment particles, and difficulty in using yellow pigment, and achieve fine particle size, short production process, shorten the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of praseodymium yellow pigment, comprises the following steps:

[0030] In the mixed solution of C1-C4 alcohol solvent, water and surfactant, soluble zirconium source, soluble praseodymium source and soluble silicon source react under the condition of pH value of 6-11 to obtain precipitate;

[0031] mixing the precipitate with a mineralizer and water and then spray-drying to obtain granules;

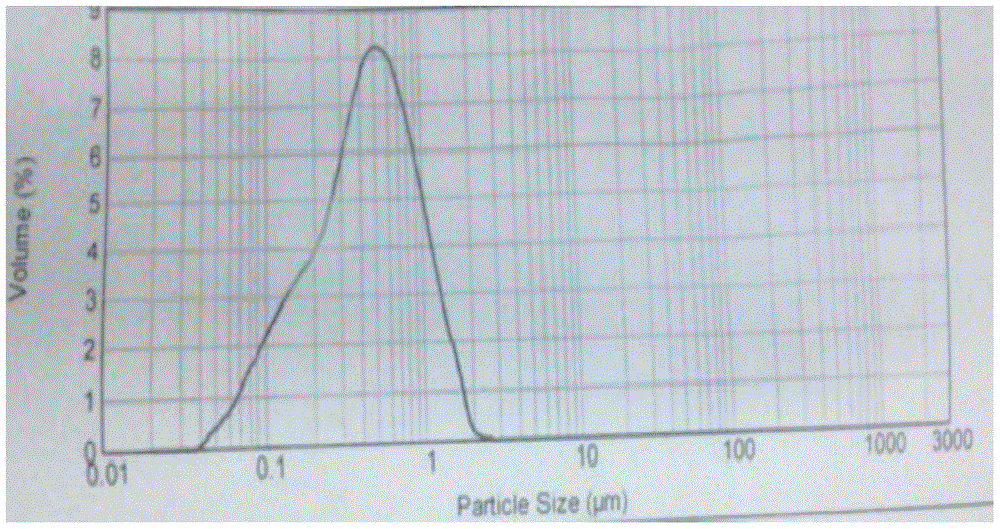

[0032] After the particles are calcined, they are sequentially pulverized and ground to obtain ultrafine particles;

[0033] The ultrafine particles are post-treated to obtain praseodymium yellow pigment.

[0034] In the present invention, the soluble zirconium source, soluble praseodymium source and soluble silicon source are used in liquid phase conditions to generate precipitates with uniform microscopic components, fine particle size and high surface activity, which can effectively reduce subsequent mineralization The amoun...

Embodiment 1

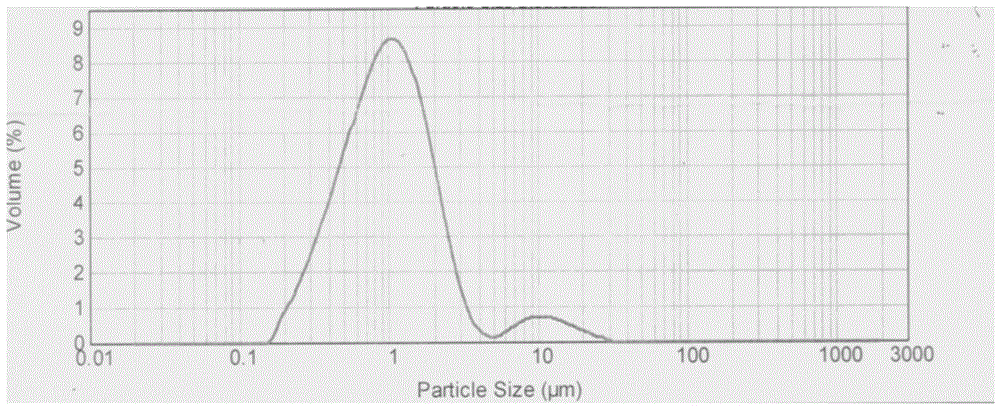

[0053] A 10L aqueous solution dissolved with 110g of praseodymium nitrate hexahydrate, 2000g of zirconium nitrate trihydrate and a 10L aqueous solution dissolved with 615g of sodium silicate were simultaneously dropped into a reaction kettle with a 13L mixed solution, the mixed solution including water, ethanol, TritonX -100 and cyclohexane, the volume fraction of ethanol is 30%, the concentration of TritonX-100 is 5mL / L, and the concentration of cyclohexane is 13mL / L; Add a solution containing 0.5wt% sodium oxalate and 50wt% sodium hydroxide to maintain the pH of the reaction solution at 8.5, stir while adding dropwise, stop the dropwise addition after 2 hours, and continue the constant temperature reaction for 2 hours under stirring;

[0054] After the reaction is completed, filter and dehydrate the reaction product, take out the filter cake and add pure water of 1 times the mass of the filter cake, 5wt% sodium chloride, 0.1wt% potassium chloride, 1.5wt% ammonium chloride 1, ...

Embodiment 2

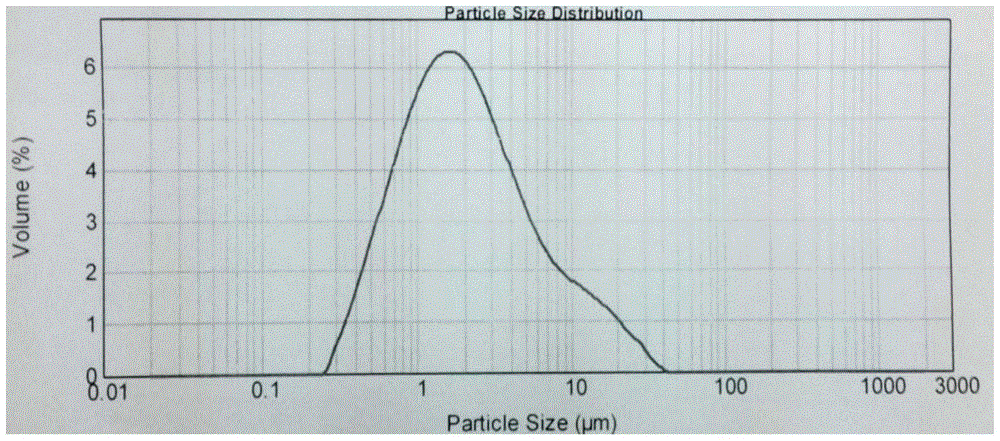

[0058] A 10L aqueous solution in which 110g of praseodymium nitrate hexahydrate and 2000g of zirconium nitrate trihydrate were dissolved and a 10L aqueous solution in which 735g of sodium silicate was dissolved were simultaneously dropped into a reaction kettle with a 13L mixed solution, the mixed solution comprising water , ethanol, n-octanol and polyethylene glycol, the volume fraction of ethanol is 45%, the concentration of n-octanol is 5mL / L, and the concentration of polyethylene glycol is 8g / L; the material obtained is reacted at 45°C During the reaction, add dropwise a solution containing 2wt% sodium oxalate and 30wt% sodium hydroxide to keep the pH of the reaction solution at 9.5, stir while adding dropwise, stop the dropwise addition after 2.5h, and continue the constant temperature reaction for 1h under stirring ;

[0059] After the reaction is completed, the reaction product is filtered and dehydrated, the filter cake is taken out and pure water of 1 times the mass o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com