Caragana microphylla bio-compound particle feed

A technology of composite granules and caragana, applied in animal feed, animal feed, application, etc., can solve the problems of ineffective digestion and utilization of crude fiber, inability to effectively improve the feeding value of caragana, and failure to meet the needs of breeding, etc., to achieve Improve the utilization rate of caragana forage and feed value, improve the utilization rate of digestion and palatability, reduce the incidence of rumen and the effect of breeding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

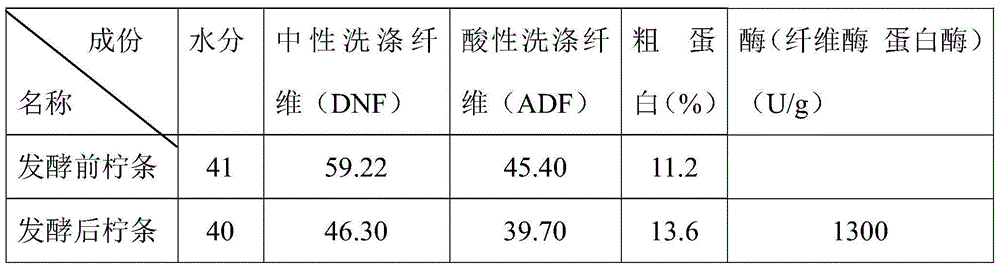

[0023] Embodiment 1 fermented caragana:

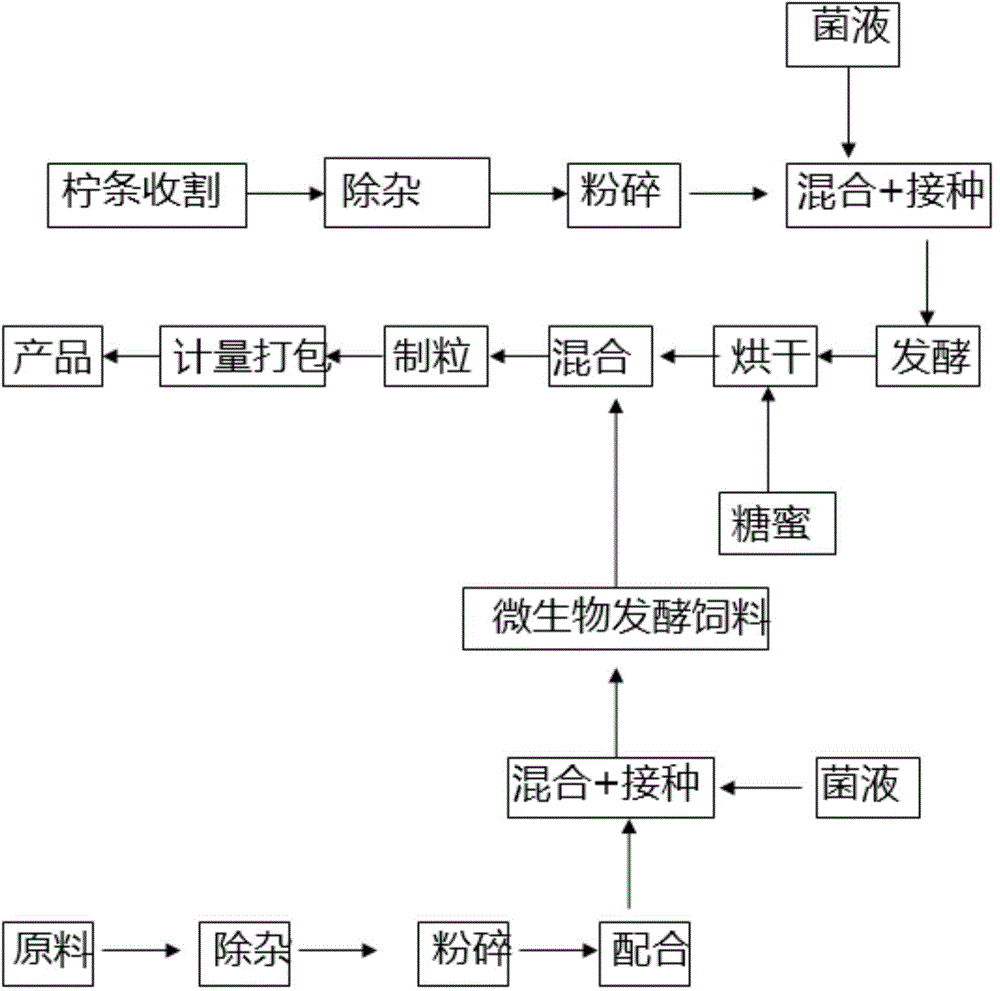

[0024] After the caragana is harvested by the shrub stubble machine, there is no need to dry it. The caragana is crushed to less than 5mm grass powder, the mass percentage is 5% corn flour, 0.2% urea, and 0.1 bacterial liquid spray, mix evenly and anaerobically ferment in the fermentation tank 10-15 days. The bacteria solution is a mixture of Bacillus subtilis, Lactobacillus, yeast and Aspergillus according to the number of bacteria 1:1:1:1. The fresh caragana (shrub) is treated with a variety of beneficial microorganisms by supplementing nitrogen sources to improve the decomposition utilization rate of cellulose and the protein content of bacteria, and make full use of the water content of the caragana itself for fermentation to maintain the natural ecological effect of beneficial microbial fermentation. Through anaerobic fermentation treatment with a variety of probiotics, the long chain of caragana cellulose is changed to short cha...

Embodiment 2

[0028] Embodiment 2 microbial fermented feed:

[0029] Mix the following ingredients by weight percentage:

[0030] Soybean meal 25, cotton meal 10, corn gluten meal 10, subwheat 10, corn 14, feed grade stone powder 5, ruminant premix 3 (trace elements, vitamins), calcium hydrogen phosphate 4, bacterial liquid 20, raw materials crushed to fine The temperature is 80 mesh, and the anaerobic fermentation temperature is 26-37°C for 7-9 days. Through the fermentation treatment of the above formula feed, the soluble metal element ions in the trace elements and the organic acids produced in the fermentation process, polysaccharide derivatives, proteins, small peptides, amino acids and other ligands are in a certain ratio (1-3) A complex formed by covalent bonds or ionic bonds, that is, organic trace elements. It has the characteristics of high absorption rate, good stability, high biological efficiency and little environmental pollution.

[0031] The ruminant premix 3 includes tra...

Embodiment 3

[0034] Embodiment 3 mixes two kinds of feeds:

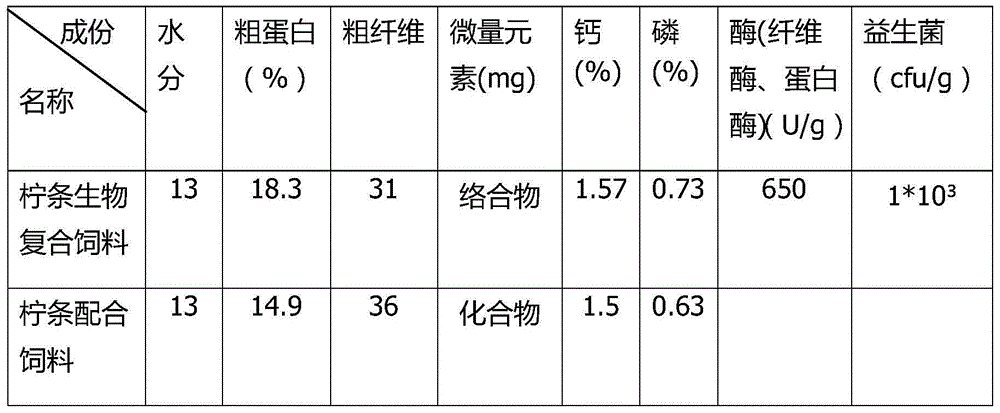

[0035] Dried fermented caragana powder (water content 9%), no need to dry microbial fermented feed (water content 32%), mix 70% fermented caragana powder with 30% microbial fermented material before granulation, and then directly The granulated caragana biological compound feed does not need steam heating and tempering, and the forming rate of feed granules is over 90%. After the microbial fermented feed and dried fermented caragana powder are mixed and granulated, due to the high moisture content of the microbial fermented feed, it will penetrate into the low water content caragana fiber, making the fiber swell and loose, and at the same time, the beneficial bacteria and many Soluble nutrients such as a highly active digestive enzyme have a double enzymolysis effect on caragana fiber.

[0036] Caragana biological compound feed has good palatability and sour flavor, herbivores like to eat, crude fiber is significantly reduced, cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com