Method for producing penicillin G acylation enzyme by fermentation by using casein hydrolysate as nitrogen source

A technology of casein hydrolyzate and penicillin, which is applied in the field of fermentative production of penicillin G acylase, can solve problems such as not being able to meet large-scale industrial production, complex work of genetically engineered bacteria, poor genetic stability of strains, etc., to increase product types and Quantity, reduce production costs, improve the effect of economic efficiency of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

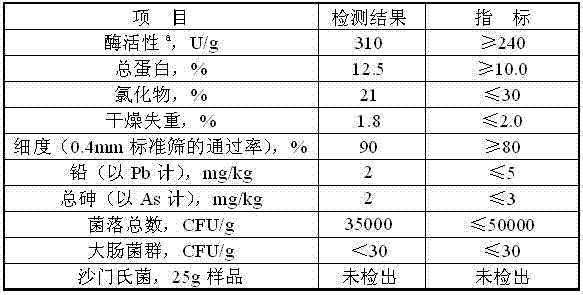

Image

Examples

Embodiment Construction

[0032] The method for fermenting and producing penicillin G acylase with casein hydrolyzate as a nitrogen source comprises the following steps:

[0033] ⑴ Preparation of slant medium:

[0034] Mix 5g of yeast powder, 10g of peptone, 10g of sodium chloride, 15g of agar with 1L of distilled water, adjust the pH value to 7.0 with a sodium hydroxide solution with a mass concentration of 10%~20%, and fill / pour into 20ml test tubes and 6cm in diameter respectively. In a plate, maintain 1kg(f) / cm in an autoclave 2 Sterilize for 30 minutes, then take it out, and let it cool and solidify naturally, that is to say, a test tube and a plate with a slant medium are respectively obtained.

[0035] ⑵ Bacillus cereus (Bacillus cereus) 21090 as the starting strain, aseptically inoculate Bacillus cereus on the slant medium in the test tube containing the slant medium (Bacillus cereus) 21090, placed in a constant temperature incubator at 30°C for 48 hours to obtain activated strains.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com