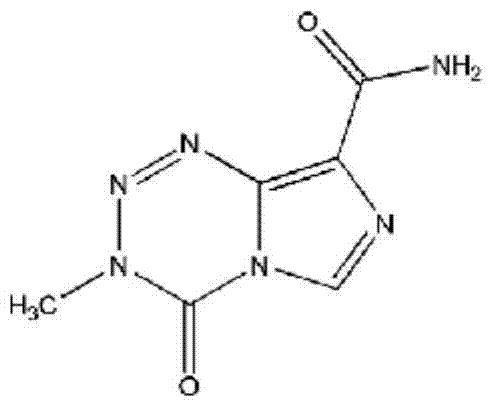

A kind of temozolomide freeze-dried powder preparation and preparation method thereof

A technology of temozolomide and freeze-dried powder, which is applied in the field of pharmaceutical preparations, can solve the problems of slow process batching, doubts about product quality, inconvenience in clinical use and risks, etc., so as to ensure product safety and effectiveness, ensure that products can be industrially scaled, and The effect of reducing the risk of clinical medication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

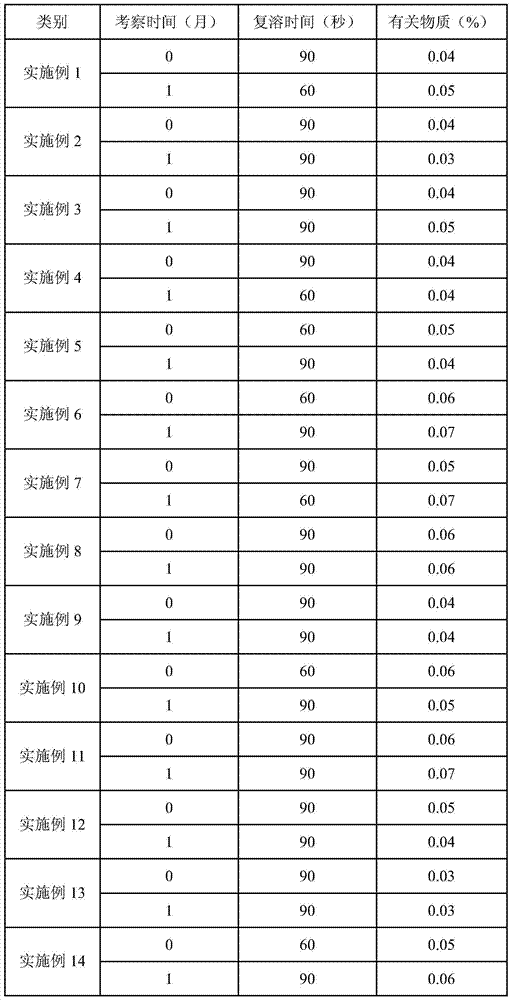

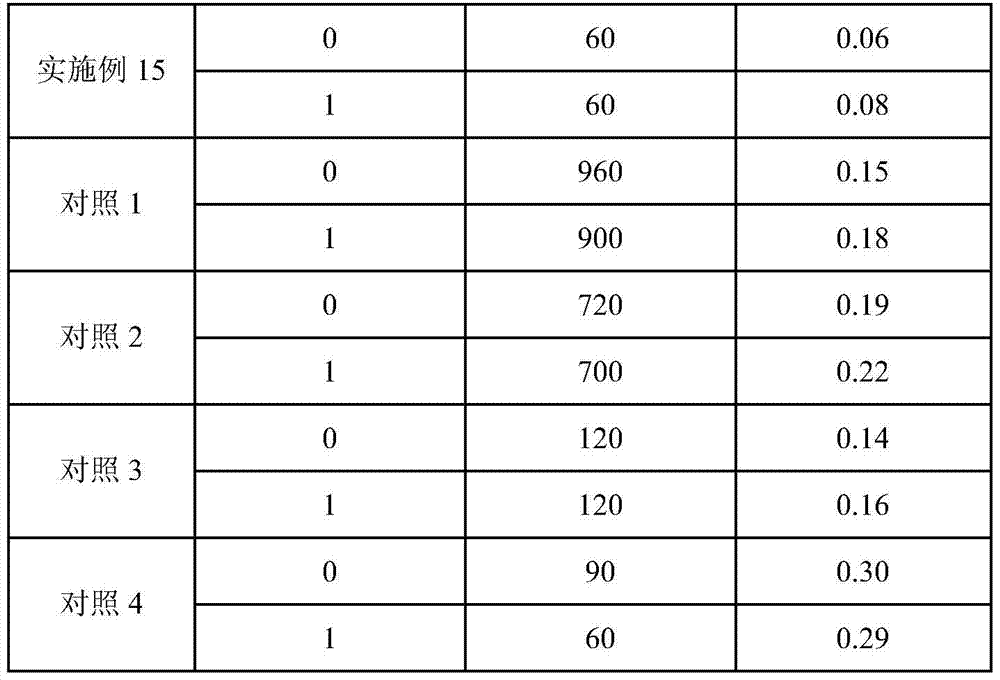

Examples

Embodiment 1

[0043] Temozolomide

[0045] Preparation method: Add 60g of mannitol, 12g of polysorbate 80, 23.5g of sodium citrate, and 4g of sodium chloride into water for injection in sequence, stir and dissolve completely, and adjust the pH to 3.7 with hydrochloric acid. Disperse temozolomide into 40ml ethanol with a high-shear dispersing emulsifier to obtain a dispersion. Add the dispersion to the above aqueous solution. After stirring and dissolving completely, set the volume to 4000ml. The feed solution is sterilized and filtered through a 0.22 μm microporous membrane, and then separated. Pack into 100ml vials, 40ml per bottle, and freeze-dry to obtain temozolomide freeze-dried powder preparation.

Embodiment 2

[0047] Temozolomide

[0048] Preparation method: Add 60g of mannitol, 12g of polysorbate 80, 23.5g of sodium citrate, and 5g of sodium chloride into water for injection in sequence, stir and dissolve completely, and adjust the pH to 3.0 with hydrochloric acid. Use a high-shear dispersing emulsifier to disperse temozolomide into 180ml of ethanol to obtain a dispersion, add the dispersion to the above aqueous solution, stir and dissolve completely, set the volume to 4000ml, filter it through a 0.22μm microporous membrane, and pack it into 100ml In vials, 40ml per bottle, freeze-dried to obtain temozolomide freeze-dried powder preparation.

Embodiment 3

[0050] Temozolomide

[0051] Preparation method: Add 60g of mannitol, 15g of polysorbate 80, 23.5g of sodium citrate, and 5g of sodium chloride into water for injection in sequence, stir and dissolve completely, and adjust the pH to 4.5 with hydrochloric acid. Use a high-shear dispersing emulsifier to disperse temozolomide into 10ml of ethanol to obtain a dispersion, add the dispersion to the above aqueous solution, stir and dissolve completely, set the volume to 4000ml, filter it through a 0.22μm microporous membrane, and pack it into 100ml In vials, 40ml per bottle, freeze-dried to obtain temozolomide freeze-dried powder preparation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com