Licking brick for preventing and treating dairy cow ketosis

A dairy cow ketone and brick licking technology, applied in metabolic diseases, medical preparations containing active ingredients, animal feed, etc., can solve the problems of recurrence rate, high recurrence frequency, short duration of drug effect, and curing the symptoms but not the root cause. Relief of neurological symptoms, strong palatability, and simple administration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

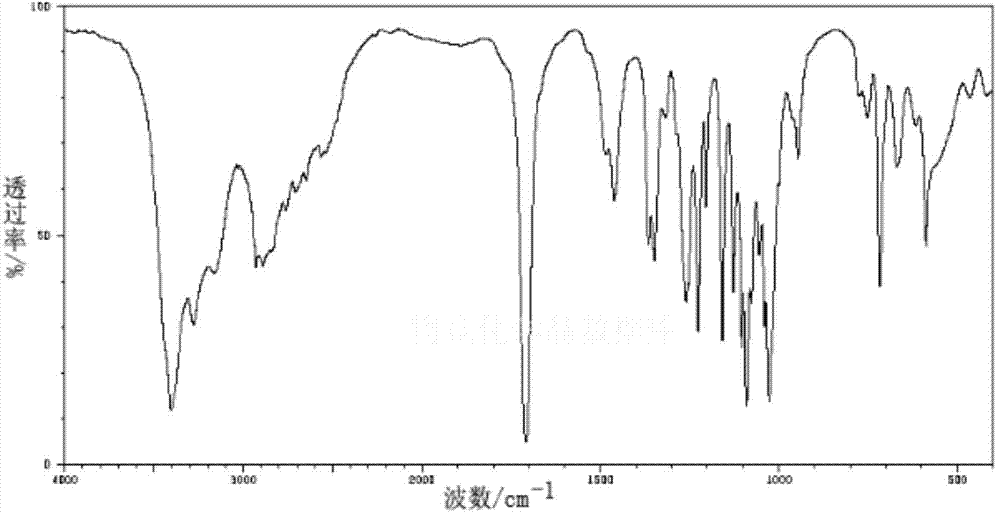

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment 1: The licking brick for preventing and treating cow ketosis in this embodiment mainly consists of 20-30g chloral hydrate, 150-250g xylitol, 200-300g propylene glycol, 4-5g nicotinic acid, 25-35g nicotinic acid, 25- 35g lysine, 40-60g methionine and 700-1000g molasses.

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the licking brick for preventing and treating dairy cow ketosis also includes 150-250g sodium bicarbonate, 20-30g calcium propionate, 25-35g biotin, 25-35g Folic acid, 1-3g ferric oxide, 3-4g copper sulfate, 0.5-1g manganese sulfate, 0.5-1g cobalt sulfate, 10-15g zinc sulfate, 10-15g magnesium carbonate, 0.5-1g calcium iodate, 1-5g Sodium selenite, 10-30g vitamin B6, 40-60g vitamin C, 10-30g vitamin E, 5-15g vitamin A, 20-40g vitamin D, 250-350g urea, 250-350g table salt, 150-250g silicic acid Salt cement and 1765-2855g loess. Other steps and parameters are the same as those in Embodiment 1.

[0020] Mineral element additives and vitamins in the licking bricks in this embodiment can increase nutritional elements, which are essential substances for the body to maintain normal physiological needs and maintain production needs; It is bonded together to form, and has a certain ...

specific Embodiment approach 3

[0021] Specific embodiment three: the licking brick of the prevention and treatment of dairy cow ketosis in this embodiment consists of 25g chloral hydrate, 200g sodium bicarbonate, 200g xylitol, 250g propylene glycol, 25g calcium propionate, 30g biotin, 3g niacin, 30g nicotinic acid , 30g lysine, 50g methionine, 30g folic acid, 2g ferric oxide, 3.5g copper sulfate, 0.6g manganese sulfate, 0.6g cobalt sulfate, 13g zinc sulfate, 14g magnesium carbonate, 0.6g calcium iodate, 2g selenous sodium nitrate, 20g vitamin B6, 50g vitamin C, 20g vitamin E, 10g vitamin A, 30g vitamin D, 300g urea, 300g salt, 800g molasses, 200g portland cement and 2360g loess.

[0022] After each component is mixed according to weight, it can be pressed into a licking brick of five kilograms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com