Polygonum cuspidatum endogenous bacterial strain aspergillus fumigates J3 bacterial strain for converting polydatin

A technology of Polygoniside and Aspergillus fumigatus, which is applied to microorganisms, fungi, microorganisms and other directions, can solve the problems of polluted environment, many by-products of chemical methods, and complicated reaction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Preparation of strain J3 of the present invention

[0021] Take wild Polygonum cuspidatum stalks collected from Lianyuan, Hunan Province, rinse with sterile water, then absorb the water with sterile filter paper, soak in 75% ethanol for 3-5 min, rinse with sterile water 3-4 times, 0.1% liter Sterilize with mercury for 30 seconds, and then use 75% ethanol for 1 minute. Cut off the root and stem phloem, take the xylem and cut it into small pieces of 0.5cm×0.5cm with sterile scissors. Rinse 3-4 times with sterile water and grind into a slurry in a sterilized mortar. After the grinding slurry is diluted 10-fold with sterile water, 1 ml of the grinding diluent is removed, and routinely spread on the primary screening medium. Each material was cultured three times in parallel at 28℃ for 72-120h, and the well-growing colonies with different morphologies were selected and streaked on a PDA plate. After 72h at 28℃, a single colony was collected and streaked 3 times to o...

Embodiment 2

[0022] Example 2 Preparation of fermentation broth of strain J3 of the present invention

[0023] The strain J3 of the present invention was inoculated into the PDA slant medium for activation at 28°C for 72 hours, and then 20% of the inoculum amount was connected to the transformation medium, that is, the PDB medium containing the substrate 10 mg polydatin (PDB medium: 200 g potato, glucose In 20 g, 1000 ml of water, natural pH), the fermentation broth was prepared by biotransformation at 28° C. and 180 r / min for 96 hours.

Embodiment 3

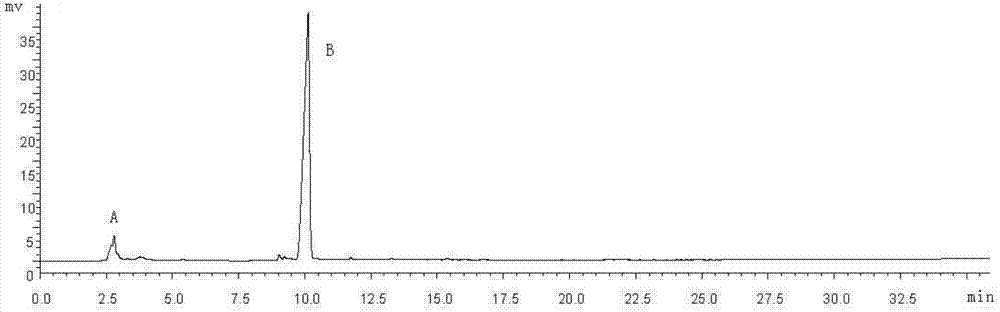

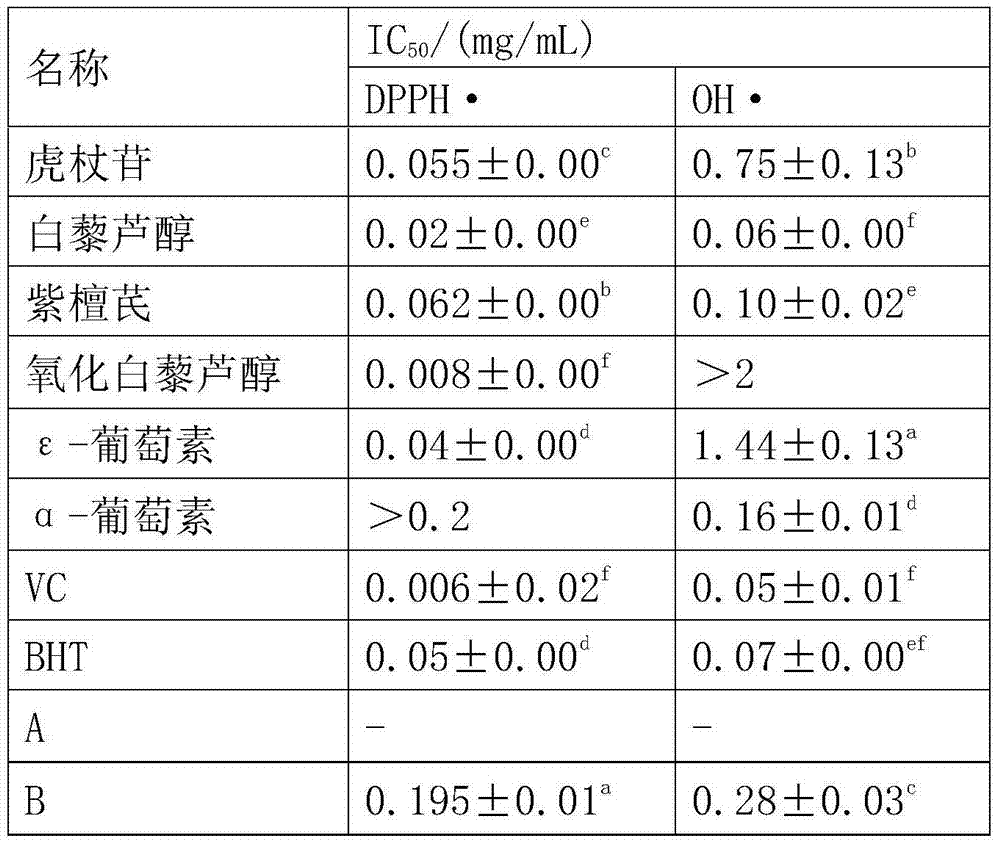

[0024] Example 3 Separation and purification of biotransformation products of fermentation broth of strain J3 of the present invention

[0025] Centrifuge the fermentation broth prepared above at 10,000 r / min for 10 min to remove mycelium and impurities, and collect the supernatant. Take 3L of the supernatant, absorb it with 300g AB-8 macroporous resin, and desorb it with 30%, 50%, 70%, 90%, and absolute ethanol, until the effluent of each stage is colorless, collect them separately, and use chloroform: methanol It is 5:1 as the developing agent, and the conversion product is detected according to TLC tracking (with the known 6 standard products of polydatin, resveratrol, α-glucin, ε-glucose, pterostilbene and oxidized resveratrol TLC developed After the development point with different Rf value is the target component), combine the collected liquids with the same Rf value and concentrate; separate the concentrated solution by preparative thin layer chromatography (PTLC), develop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com