Preparation method and application of classical swine fever virus recombinant subunit vaccine

A subunit vaccine and swine fever virus technology, applied in the field of biological vaccine preparation, can solve the problems of allergic reactions in animals, not easy to mass-produce, easy to contaminate foreign bacteria, etc., to achieve no BVDV contamination risk, low production cost, The effect of easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

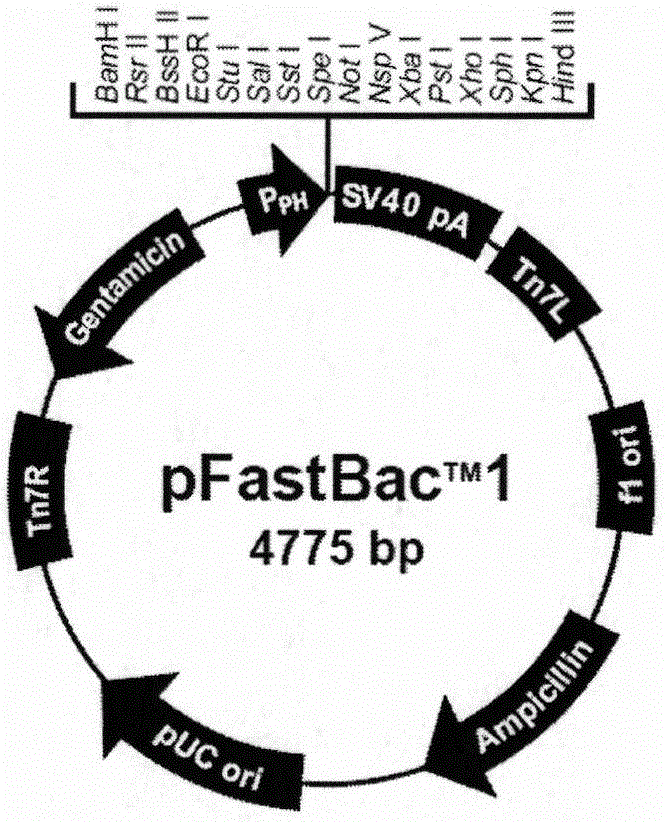

[0025] The construction of embodiment 1 expression vector

[0026] 1.1 Extraction of CSFV RNA

[0027] Trizol was used to extract RNA from the culture supernatant of CSFV as a template for reverse transcription.

[0028] 1.2 RNA reverse transcription into cDNA

[0029] Experiments were performed using takara's Primescript RT-PCR kit.

[0030] 1.3PCR amplification primers (restriction sites are underlined):

[0031] Upstream primer: 5'-CG GAATTC CTAGCCTGCAAGGAAGATTAC-3'

[0032] Downstream primer: 5'-CCC AAGCTT TTA GTGATGGTGATGGTGATGAACAAATTCTGCGAAGTAATC-3’

[0033] The sample loading system is (50μl):

[0034]

[0035] PCR amplification program:

[0036]

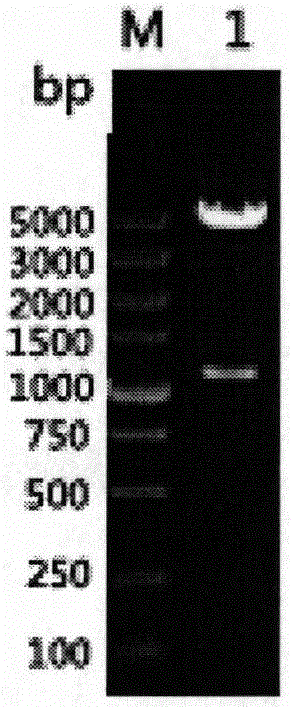

[0037] 1.4 Gel recovery of DNA fragments:

[0038] (1) Perform 1% agarose gel electrophoresis (98V 45min) on 50 μl of the system reaction solution in step 1.3;

[0039] (2) Under the ultraviolet light, cut the gel and recover the DNA fragments in a 1.5ml EP tube; use the DNA extraction kit of Tiangen Bio t...

Embodiment 2

[0078] Example 2 Recombinant pFastBac1-KSPTE2 plasmid transforms Escherichia coli DH 10Bac

[0079] (1) Take 100 μl of DH10Bac competent cells and place them on ice;

[0080] (2) Add at least 1 ng of recombinant pFastBac1-KSPTE2 plasmid to 100 μl DH10Bac competent cells, and ice-bath for 30 minutes;

[0081] (3) Heat shock in a water bath at 42°C for 45 sec, put the EP tube back on ice, and let stand for 2 min;

[0082] (4) Add 900 μl non-resistant LB culture solution in the ultra-clean bench;

[0083] (5) Shaking culture at 220 rpm at 37°C for 4 hours;

[0084] (6) After 4 hours, take 10 μl of bacterial liquid and apply KGT three-antibody plate (50 μg / ml Kanamycin, 7 μg / ml Gentamicin and 10 μg / ml Tetracycline, 100 μg / ml Bluo-gal, and 40 μg / ml IPTG), and incubate at 37°C in the dark 48h;

[0085] (7) Select the white spot and transfer it to the KGT third antibody plate to continue culturing at 37°C for about 24 hours. Afterwards, uniform white spots were selected, and eac...

Embodiment 3ba

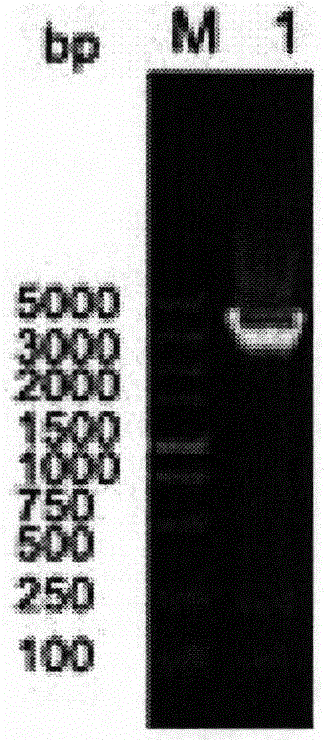

[0087] Example 3 bacmid-KSPTE2 extraction

[0088] (1) Transfer the white spot bacterial liquid identified as positive by PCR to 5ml KGT tertiary antibody LB liquid medium and continue overnight culture at 37°C and 225rpm;

[0089] (2) Inoculate 1ml of overnight cultured bacterial solution into 100ml KGT triple antibody LB liquid medium to continue overnight culture at 37°C 225rpm, and extract the Bacmid plasmid according to the alkaline lysis method;

[0090] (3) Divide the cultured bacterial solution into two 50ml centrifuge tubes, and centrifuge at 12,000rpm at 4°C for 10min;

[0091] (4) Discard the supernatant, blot up the culture medium as much as possible, recover the bacteria, add 10ml of ice-cooled solution I (50mmol / L glucose, 25mmol / L Tris HCl, 10mmol / L EDTA, pH 8.0, add 40μg / ml RNase A) Tap gently with a pipette to completely suspend the bacteria;

[0092] (5) Add 20ml of freshly prepared solution II (1% SDS, 0.2M NaOH), cap the tube tightly, gently invert the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com