A detoxification method for lignocellulosic raw material prehydrolyzed sugar solution

A lignocellulosic raw material, pre-hydrolysis technology, applied in the direction of biofuel, fermentation, etc., can solve the problems of fermentation sugar loss, secondary pollution, poor effect, etc., to achieve the effect of improving sugar utilization rate, ethanol production and fermentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The steps for obtaining the concentrated liquid of lignocellulosic raw material prehydrolyzed sugar solution are as follows:

[0028] (1) Dilute acid steam explosion pretreatment: corn stalks were collected in Hohhot, Inner Mongolia. The mass fractions of cellulose and hemicellulose in corn stover were 37.17% and 22.84%, respectively. Corn stalks are soaked in sulfuric acid with a mass fraction of 0.50% to 1.00% for 1 to 3 hours, dehydrated to a solid content of 30% to 40%, treated at 1.6 to 2.0MPa for 5 to 10 minutes, and instantly open the discharge valve of the blasting device. Spray the material into the trough.

[0029] (2) Water washing pretreatment of corn stalks: wash the material three times with warm water with a solid-to-liquid ratio of 1:15, collect the filtrate (that is, the prehydrolyzed sugar solution of acidic blasted corn stalks) and filter residues for later use.

[0030] (3) Concentration of pre-hydrolyzed sugar solution: the corn stalk pre-hydrolyz...

Embodiment 2

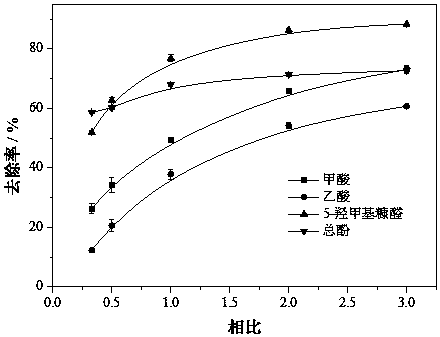

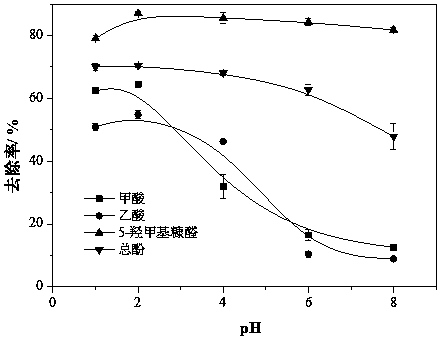

[0037] The detoxification treatment of the lignocellulosic raw material prehydrolyzed sugar solution concentrate prepared in Example 1, the process is as follows:

[0038] 1) Washing of ionic liquid: Pipette 5 mL of 1-hexyl-3-methylimidazolium tetrafluoroborate [C 6 mim][BF 4 ], 1-octyl-3-methylimidazolium tetrafluoroborate [C 8 mim][BF 4 ] The ionic liquid and distilled water were mixed at a ratio of 1:1 and placed in a shaker, and reacted at 30°C and 150r / min for 20min. After washing with water, the mixed phase of water and ionic liquid was centrifuged at 4000r / min for 10min, and after the centrifugation, it was allowed to stand for 20min to separate the layers, and the ionic liquid was collected, and the water-saturated ionic liquid was used as the extraction agent.

[0039] 2) Detoxification method: pipette 5mL of 1-butyl-3-methylimidazolium hexafluorophosphate C 4 mim[PF 6 ], 1-hexyl-3-methylimidazolium hexafluorophosphate C 6 mim[PF 6 ], 1-octyl-3-methylimidazoliu...

Embodiment 3

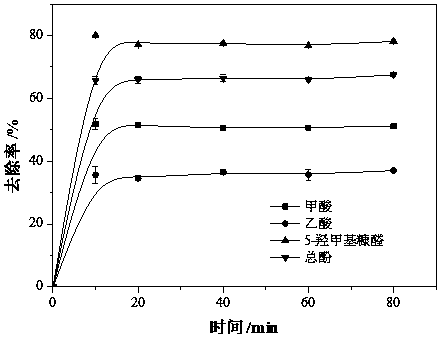

[0046] [C 8 mim][BF 4 ] Determination of extraction equilibrium time

[0047] 1) [C of ionic liquid 8 mim][BF 4 ]Washing: pipette 5mL of 1-octyl-3-methylimidazolium tetrafluoroborate [C 8 mim][BF 4 ] The ionic liquid and distilled water were mixed at a ratio of 1:1 and placed in a shaker, and reacted at 30°C and 150r / min for 20min. After washing with water, the mixed phase of water and ionic liquid was centrifuged at 4000r / min for 10min, and after the centrifugation, it was allowed to stand for 20min to separate the layers, and the ionic liquid was collected, and the water-saturated ionic liquid was used as the extraction agent.

[0048] 2) Detoxification method: pipette 5mL of 1-octyl-3-methylimidazolium tetrafluoroborate [C 8 mim][BF 4 ] In five 50mL triangles, add 5mL pre-hydrolyzed sugar liquid concentrate (pH adjusted to 2) according to the ratio of 1:1, mix, place in a shaker, and react under the conditions of 30°C and 150r / min for 10, 20, 40, 60, 80 minutes. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com