Thermostable trehalose synthase as well as expression gene and application thereof

A trehalose synthase and gene expression technology, applied in the fields of application, genetic engineering, glycosyltransferase, etc., can solve the problems of poor thermal stability, long reaction time, low substrate conversion rate, etc., and achieve the effect of increasing expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Cloning the trehalose synthase gene of Pseudomonas putida KT2440 N42-C680 fragment

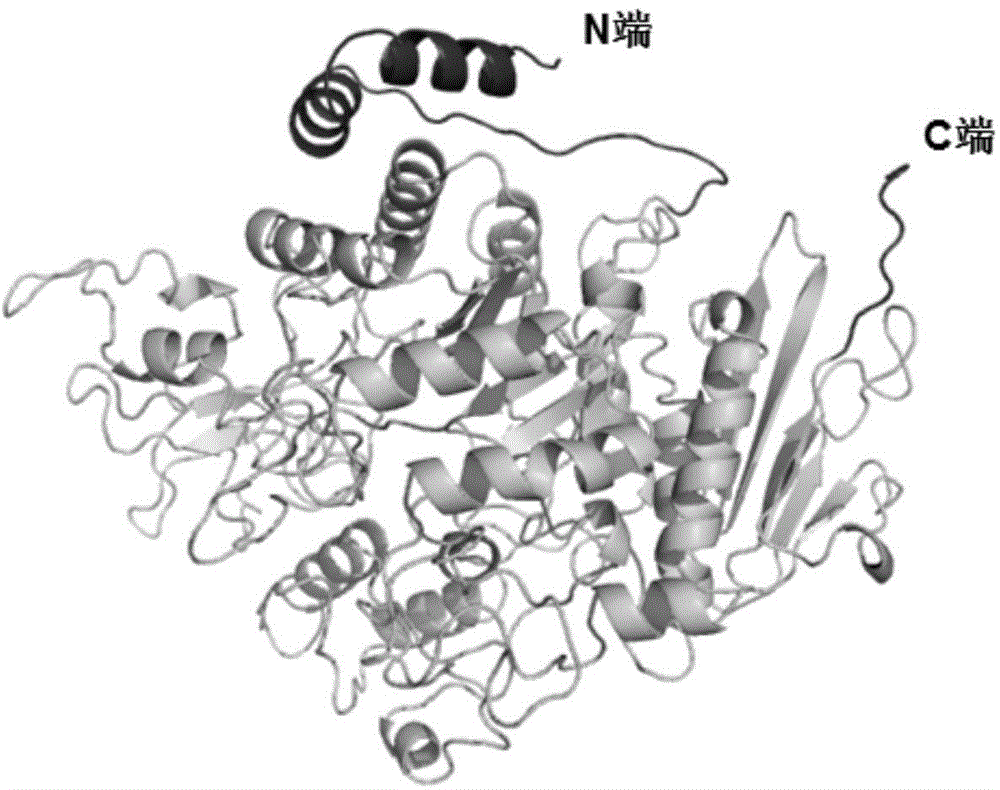

[0032] Based on the full-length amino acid sequence of Pseudomonas putida KT2440 published on NCBI, the three-dimensional structure simulation was carried out. The simulation results are as follows: figure 1 As shown, it is found that the two ends of the full-length trehalose synthase protein have obvious flexible regions, that is, the N-terminal to the 41st glutamic acid and the 680th isoleucine to the C-terminal. Design primers to remove the flexible regions at both ends, and the primer sequences are as follows:

[0033] Upstream primer: 5'-atc gga tcc ATG GCCCAGCCCCGC-3';

[0034] Downstream primer: 5'-tca ctc gag tta CCGCAGGCACAG-3';

[0035] Using the full-length gene of Pseudomonas putida KT2440 as a template, PCR amplification was performed using the above primers. The PCR reaction system was as follows:

[0036]

[0037] The above-mentioned PCR reaction is carri...

Embodiment 2

[0040] Example 2: Transforming the modified trehalose synthase gene into an expression host to obtain a positive expression strain.

[0041] Double digestion reaction of PCR product and plasmid vector

[0042] Enzyme digestion system for PCR products:

[0043]

[0044] Reaction conditions: react at 37°C for 2 to 3 hours.

[0045] Enzyme digestion system for plasmid vectors:

[0046]

[0047] Reaction conditions: react at 37°C for 6-8 hours.

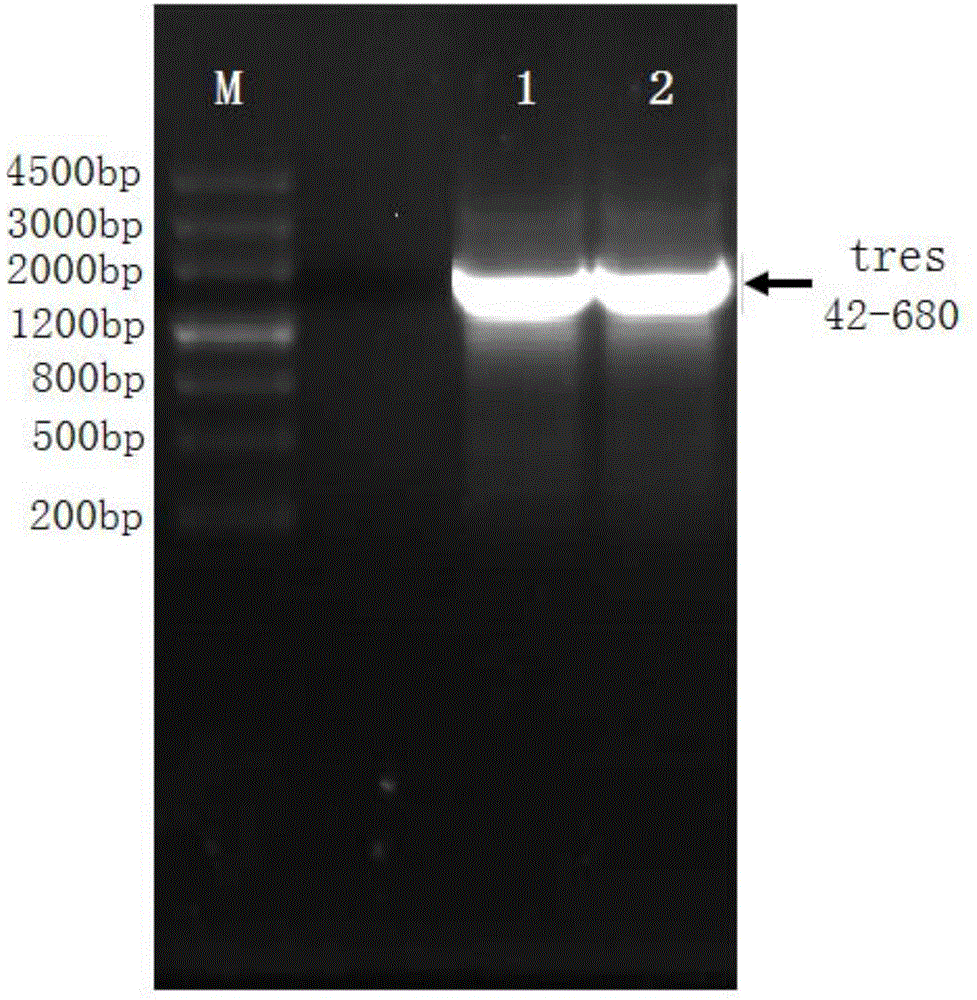

[0048] The PCR product and the vector digested product were subjected to 1% agarose gel electrophoresis, and were purified and recovered using a DNA gel recovery kit.

[0049] Connection reaction system:

[0050]

[0051] Mix well and centrifuge for a few seconds, collect the drop on the tube wall to the bottom of the tube, and connect overnight at 16°C to obtain the ligated product.

[0052] Transformation of recombinant plasmids

[0053] (1) Preparation of Competent Cells

[0054] ①Pick a single colony of BL21 (or pick a p...

Embodiment 3

[0076] Example 3: Fermentation and culture of positive expression strains, separation and purification of recombinant recombinant trehalose synthase protein

[0077] Seed culture: Pick positive clones in a conventional method and place them in 5 mL of LB liquid medium containing 100 mg / L ampicillin, and shake and culture at 37°C for 5-6 hours;

[0078] Ultrasonic disruption of bacterial cells: ultrasonic 3s, interval 6s, 400W, work 60 times.

[0079] Ultracentrifugation: after sonication, the cell disruption solution was centrifuged at 14000rpm, 4°C for 45min, and the supernatant was collected for the next step of separation and purification.

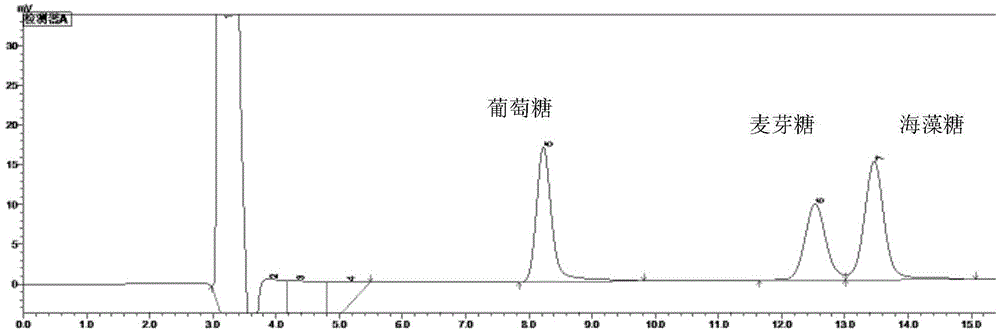

[0080] Ni-NTA affinity chromatography: pour the collected supernatant containing soluble protein into the regenerated Ni-NTA column; , 15mM imidazole) to wash 10 column volumes to remove non-specifically adsorbed proteins; finally use elution buffer (25mM Tris-HCl, pH8.0, 100mM NaCl, 250mM imidazole) to elute the target protein and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com