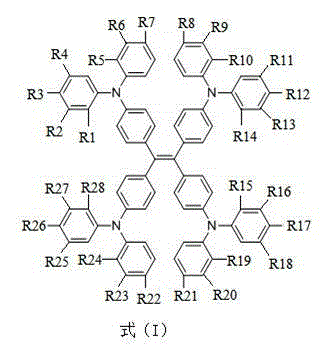

Novel hole transport material, and preparation method and application thereof

A hole transport material and a new type of technology, which are applied in the field of new hole transport materials and their preparation, can solve the problems of high price, cumbersome synthesis and purification, restricting the development and popularization of perovskite solar cells, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation method

[0048](1) Under the protection of argon, add zinc powder to the double-necked round bottom flask, place it at -10°C, add 10mL tetrahydrofuran, slowly add titanium tetrachloride dropwise, reflux at 85°C for 2.5 hours, and cool to room temperature, then add 4,4'-dibromobenzophenone solution dissolved in 15mL tetrahydrofuran and pyridine at -10°C, reflux for 12 hours, stop the reaction, cool to room temperature, add sodium carbonate solution until the solution is alkaline, Extracted three times with ethyl acetate, with anhydrous MgSO 4 The organic layer was dried, and the crude product was separated by silica gel column chromatography (petroleum ether) to obtain a white solid.

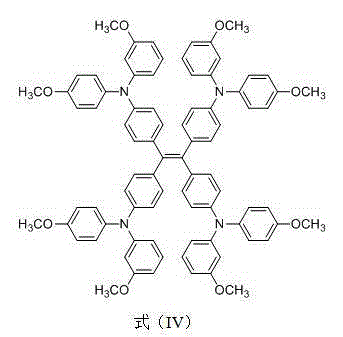

[0049] (2) Under argon protection, add 4,4',4'',4'''-tetrabromotetraphenylethylene, 4,4'-dimethoxydiphenylamine, tert-butanol into the two-necked bottle Sodium, palladium acetate, add 5mL of toluene, stir to dissolve, add tri-tert-butylphosphine, place it at 110°C for reac...

Embodiment 2

[0056] 1. Preparation method

[0057] (1) Under the protection of argon, add zinc powder to the double-necked round bottom flask, place it at -10°C, add 10mL tetrahydrofuran, slowly add titanium tetrachloride dropwise, reflux at 85°C for 2.5 hours, and cool to room temperature, then add 4,4'-dibromobenzophenone solution dissolved in 15mL tetrahydrofuran and pyridine at -10°C, reflux for 12 hours, stop the reaction, cool to room temperature, add sodium carbonate solution until the solution is alkaline, Extracted three times with ethyl acetate, with anhydrous MgSO 4 The organic layer was dried, and the crude product was separated by silica gel column chromatography (petroleum ether) to obtain a white solid.

[0058] (2) Under the protection of argon, add p-iodoanisole, anthranil, palladium acetate, sodium tert-butoxide, tri-tert-butylphosphine and toluene into a double-necked round bottom flask, and heat to 100°C , reacted for 21 hours, stopped the reaction, added saturated am...

Embodiment 3

[0066] 1. Preparation method

[0067] (1) The first step: under the protection of argon, add zinc powder into the double-necked round bottom flask, place it at -10°C, add 10mL of tetrahydrofuran, slowly add titanium tetrachloride dropwise, and reflux at 85°C for 2.5 hours, cooled to room temperature, then added 4,4'-dibromobenzophenone solution and pyridine dissolved in 15mL tetrahydrofuran at -10°C, refluxed for 12 hours, stopped the reaction, cooled to room temperature, added sodium carbonate solution to the solution Alkaline, extracted three times with ethyl acetate, and anhydrous MgSO 4 The organic layer was dried, and the crude product was separated by silica gel column chromatography (petroleum ether) to obtain a white solid.

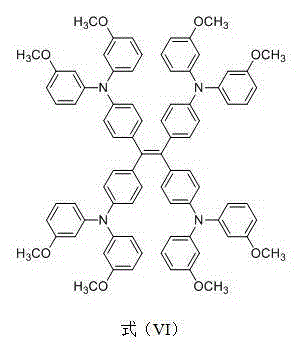

[0068] (2) The second step: under the protection of argon, add p-iodoanisole, m-aminoanisole, palladium acetate, sodium tert-butoxide, tri-tert-butylphosphine and toluene into a double-necked round bottom flask, Heat to 100°C, react for 23 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com