Preparation method for yeast recombinant expression of insulin aspart

A technology of insulin aspart and yeast is applied in the field of recombinant protein preparation under biotechnology, which can solve the problems of high enzyme dosage and low yield, and achieve the effects of high enzyme cleavage efficiency, high coupling rate and low miscleavage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Example 1. Upstream construction and screening of recombinant insulin aspart

[0039](1) Design its cDNA sequence based on the amino acid sequence of recombinant human proinsulin proaspart, and design two stop codon sequences TGA and TAA behind the sequence, and design XhoI (CTCGAG) and NtoI ( GCGGCCGC) restriction enzyme site. Entrust Dalian TAKARA Engineering Co., Ltd. to carry out the whole gene synthesis.

[0040] (2) Insert the Pro-Asp cDNA synthesized by the above-mentioned whole gene into the PMD18-T-Pro-Asp plasmid. PMD18-T-Pro-Asp and pPICZα A were digested with restriction enzymes respectively, and two target fragments (Pro-Asp and pPICZα A large fragment) were recovered, linked by T4 and transformed into P. Pastoris X-33 host bacteria In this method, engineering bacteria (pPICZαA-Pro-Asp / X-33) were obtained.

[0041] (3) By screening highly expressed engineering bacteria and optimizing the fermentation process, recombinant proinsulin aspart was obtained. ...

example 2

[0051] Example 2. Preparation of insulin aspart

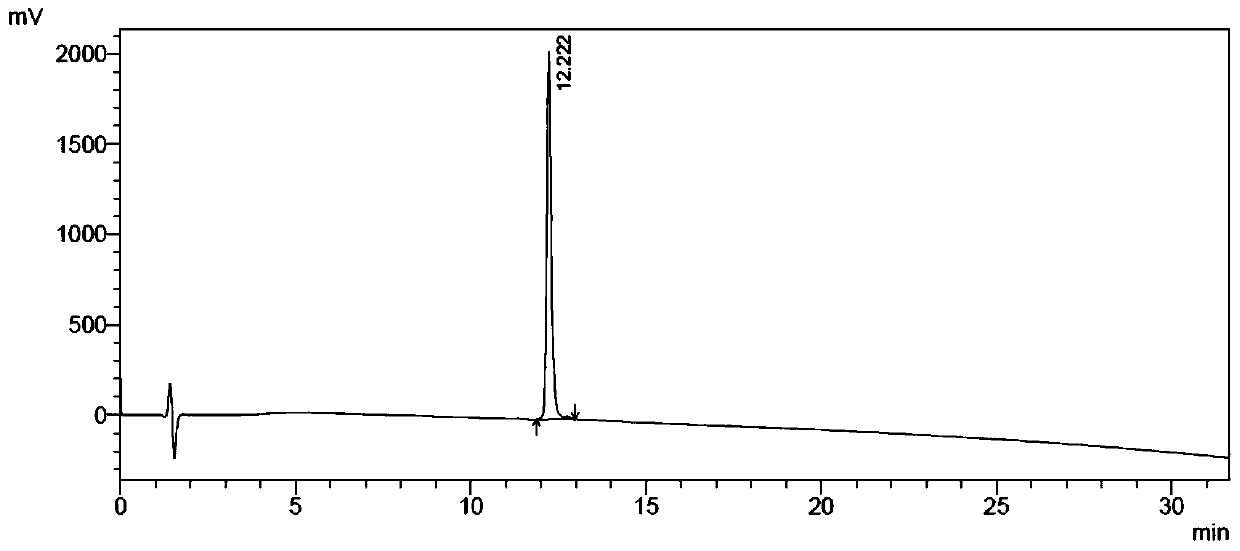

[0052] (1) Purification to obtain proinsulin aspart and enzymatic digestion to obtain missing B30-insulin aspart: 5L of Pichia pastoris fermentation broth, centrifuged, and the supernatant was subjected to copper ion chelation chromatography and SP cation exchange chromatography to obtain aspart Proinsulin; then add 20mM Zn ion to precipitate proinsulin aspart, centrifuge, dissolve the precipitate with 100ml 50mM Tris, the protein content is 1g, adjust the pH to 8.8, and add lysyl in the ratio of enzyme to protein at 1:5000 Peptidase (Lys-C) 0.2 mg, digestion at 30°C with stirring. After 16 hours, samples were taken for RP-HPLC analysis, and the enzyme digestion efficiency reached 90%, and the pH was adjusted to 5.5 for isoelectric point precipitation.

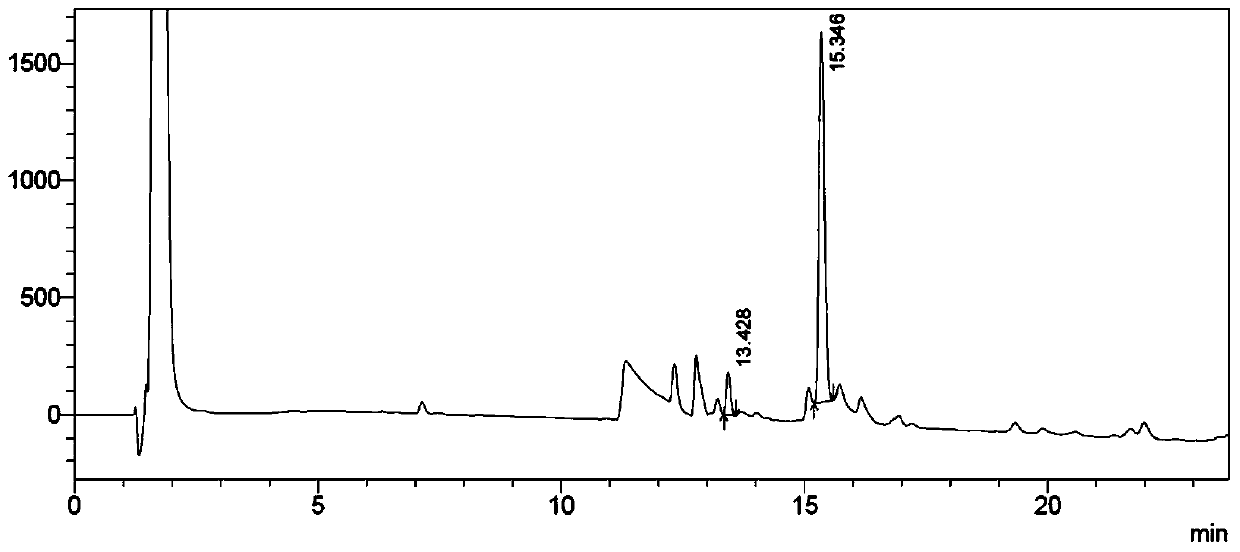

[0053] (2) Coupling of desB30-insulin aspart to obtain insulin aspart ester: take isoelectric point precipitate desB30-insulin aspart, centrifuge, dissolve with 5ml 10% glacia...

example 3

[0057] Example 3. Optimization of the preparation process of insulin aspart

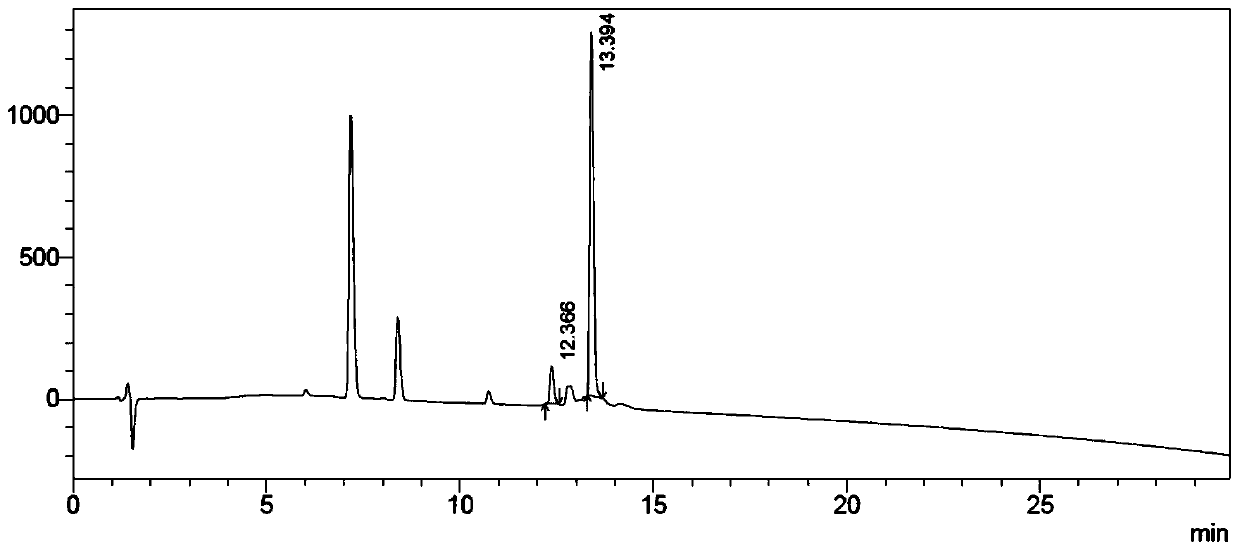

[0058] (1) Purification to obtain proinsulin aspart and enzymatic digestion to obtain DesB30-insulin aspart: Pichia pastoris fermentation broth, centrifugation, supernatant per copper ion chelation chromatography and SP cation exchange chromatography for proaspart; Then add Zn to precipitate proinsulin aspart, centrifuge, dissolve the precipitate with 300ml 50mM Tris, the protein content is 2.5g, adjust the pH to 9.0, add lysyl endopeptidase (Lys -C) 0.25mg, digested with stirring at 37°C. After 16 hours, samples were taken for RP-HPLC analysis, and the enzyme digestion efficiency reached 95%, and the pH was adjusted to 5.0 for isoelectric point precipitation.

[0059] (2) Deletion of B30-insulin aspart coupling to obtain insulin aspart ester: take the isoelectric point precipitate DesB30-insulin aspart and centrifuge, dissolve with 10ml 10% glacial acetic acid, the protein concentration is 100mg / ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com