Single-component self-crosslinking waterborne polyurethane sustained/controlled release coated material

A water-based polyurethane, coating material technology, applied in the direction of layered/coated fertilizer, fertilizer mixture, application, etc., can solve the problem that the improvement effect of fertilizer utilization rate is not obvious, the soil structure is easily damaged, and the slow and controlled release effect is not good, etc. To achieve the effect of increasing the content of soil available phosphorus, being environmentally friendly and improving the utilization rate of phosphorus fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

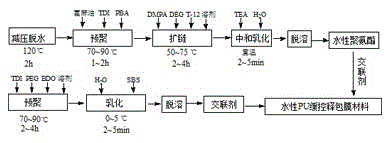

Method used

Image

Examples

Embodiment 1

[0027] Example 1: One-component self-crosslinking waterborne polyurethane slow and controlled release coating material

[0028] In a 250ml three-necked flask with a reflux condenser and a thermometer, add 36g of toluene diisocyanate (TDI), 30g of castor oil polyol with a hydroxyl value equal to 163mgKOH / g, and polyoxypropylene with a hydroxyl value equal to 55mgKOH / g after vacuum dehydration Diol (PPG) 20g, react at a constant temperature of 90°C for 1.5h under mechanical stirring; cool down to 80°C, add 4.2g of dimethylolpropionic acid (DMPA) and 20ml of acetone to continue the reaction for 1h to obtain a hydrophilic modified PU Prepolymer: add 40ml of acetone, wait until the system cools down to about 40°C, add 10.0g of diethylene glycol (DEG), 3 drops of dibutyltin dilaurate, and react at 60°C until the NCO content reaches the theoretical value (using Standard di-n-butylamine titration method); cool down to about 30°C, add 3.7g of triethylamine to neutralize for 2min under ...

Embodiment 2

[0031] Example 2: One-component self-crosslinking waterborne polyurethane slow and controlled release coating material

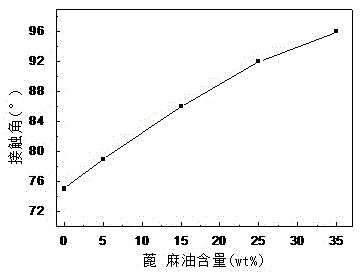

[0032] In a 250ml three-necked flask with a reflux condenser and a thermometer, add 35g of toluene diisocyanate (TDI), 40g of castor oil polyol with a hydroxyl value equal to 163mgKOH / g, and polyethylene glycol with a hydroxyl value equal to 55mgKOH / g after vacuum dehydration. Butylene glycol ester diol (PBA) 40g, react at 90°C for 1.5h under mechanical stirring; cool down to 80°C, add 4.8g of dimethylolpropionic acid (DMPA) and 20ml of acetone to continue the reaction for 1h to obtain Water-modified PU prepolymer; add 40ml of acetone, wait until the system cools down to about 40°C, add 5.5g of 1,4-butanediol (BDO), 3 drops of dibutyltin dilaurate, and react to NCO at 60°C The content reaches the theoretical value (determined by the standard di-n-butylamine titration method); cool down to about 30°C, add 3.5g of triethylamine under the action of high shear f...

Embodiment 3

[0035] Example 3: One-component self-crosslinking waterborne polyurethane slow and controlled release coating material

[0036]In a 500ml three-neck flask with a reflux condenser and a thermometer, add 91g of diphenylmethane diisocyanate (MDI), 50g of castor oil polyol with a hydroxyl value equal to 163mgKOH / g, and 50g of castor oil polyol with a hydroxyl value equal to 110mgKOH / g after vacuum dehydration Polyoxypropylene glycol (PPG) 50g, react at a constant temperature of 70°C for 1.5h under mechanical stirring; cool down to 60°C, add 7.1g of dimethylolpropionic acid (DMPA) and 20ml of acetone to continue the reaction for 1h to obtain a hydrophilic modification PU prepolymer; add 40ml of acetone, wait for the system to cool down to about 40°C, add 9.0g of 1,4-butanediol (BDO), and react at 60°C until the NCO content reaches the theoretical value (using standard di-n-butylamine determined by titration method); lower the temperature to about 30°C, add 5.3g of triethylamine und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com