Method for preparing high-purity hydroxytyrosol by using high-speed counter-current chromatography and high performance liquid chromatography in combined manner

A technology of high-speed countercurrent chromatography and high-performance liquid chromatography, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of high-purity hydroxytyrosol without batches, achieve fewer steps, increase yield, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

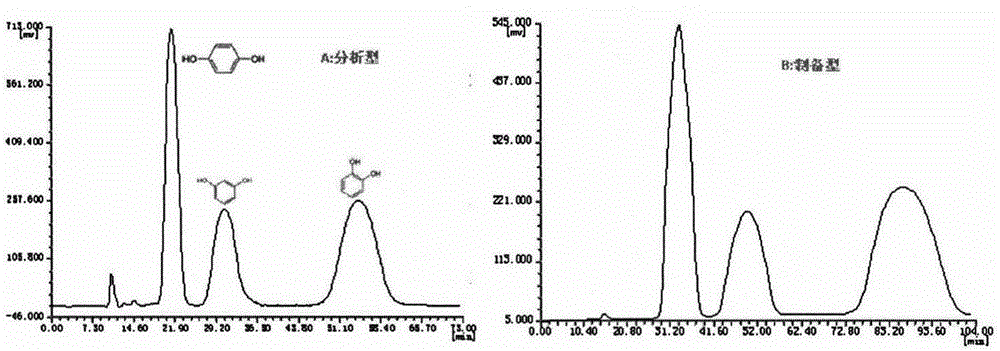

[0032] Example 1 Separation of standard samples by high-speed countercurrent chromatography

[0033] 1. Experimental equipment:

[0034] FastChrome analytical high-speed countercurrent chromatograph (Jiangyin Countercurrent Technology Co., Ltd.); separation column volume: 25ml; value range: 0.56~0.91; OptiChromeA semi-preparative high-speed countercurrent chromatograph (Jiangyin Countercurrent Technology Co., Ltd.); spiral tube separation column (revolution Radius: 80cm; Value range: 0.50~0.80; Spiral tube inner diameter: 1.59mm), single column volume 180ml, double column volume 360ml.

[0035] 2. Experimental materials:

[0036] Analysis of pure isomers of phenolic samples: catechol, resorcinol, hydroquinone; n-hexane, ethyl acetate, methanol, distilled water

[0037] 3. Preparation of solvents and samples:

[0038] Prepare the methanol mixed solution of the phenolic sample, the concentration of the mixed sample: catechol 20mg / ml+ resorcinol 20mg / ml+ hydroquinone 10mg / ml; use 80% metha...

Embodiment 2

[0059] Example 2 High-speed countercurrent chromatography and high-performance liquid chromatography combined method

[0060] The first step, preparation of hydroxytyrosol ointment

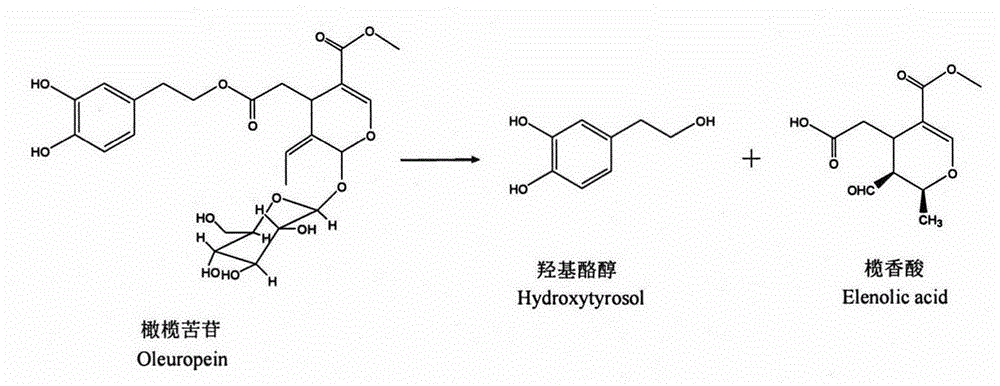

[0061] The oleuropein extract of Olea europaea is enzymatically hydrolyzed, the solid-liquid ratio of the extract and the phosphate buffer solution of 4-7 is 1g:10-100mL, and the mass ratio of the extract and the biological enzyme is 1g:20-100mg, placed in 30 ℃~100℃ in a constant temperature water bath shaker. After enzymolysis for 1h-10h, filter, the filtrate is extracted with ethyl acetate, the ethyl acetate layer is concentrated and dried, the concentrate is hydroxytyrosol ointment, the yield of the ointment relative to the plant leaf powder is 1-20%, and the hydroxytyrosol content is 5~ 20%;

[0062] The second step, high-speed countercurrent chromatography separation

[0063] 1) Select the 3-6:4-8:3-6:4-8 solution of petroleum ether: ethyl acetate: methanol: water according to the volume ratio as t...

Embodiment 3

[0068] Example 3 Experiment of separating hydroxytyrosol ointment by high-speed countercurrent chromatography

[0069] 1. Solvent preparation: petroleum ether: ethyl acetate: methanol: water=2:3:2:3. Prepare 2000ml according to the volume ratio. The upper phase is the stationary phase and the lower phase is the mobile phase.

[0070] 2. Sample preparation: Take 50 mg of hydroxytyrosol ointment in Example 3 and dissolve it in 50 ml of mobile phase.

[0071] 3. System balance: pump full stationary phase at a speed of 50ml / min, pump in mobile phase at a speed of 5ml / min, start

[0072] 4.OptiChrome TM A-300 forward centrifugation, observe the UV3000 output to reach the system balance, calculate the stationary phase retention rate: 60%

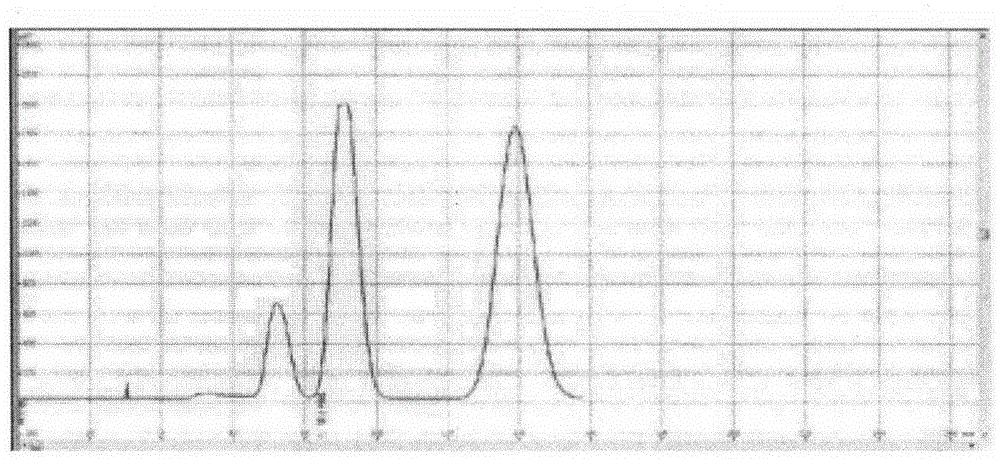

[0073] 5. Sample loading: inject the sample into OptiChrome through the sample valve TM In A-300. Forward centrifugation: OptiChrome TM A-300 is set to forward centrifugal rotation, set. The sample gets a spectrum through the detector, as attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com