Single-crystal particle film and preparation method of substrate-free flexible solar cell employing single-crystal particle film

A technology of solar cells and single crystal particles, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the adverse effects of CZTS and CZTSSe battery performance, the difficulty of high-efficiency thin film battery preparation and performance optimization, and the accompanying problems and other issues to achieve the effect of reducing the impact of defects and interface impurities on device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

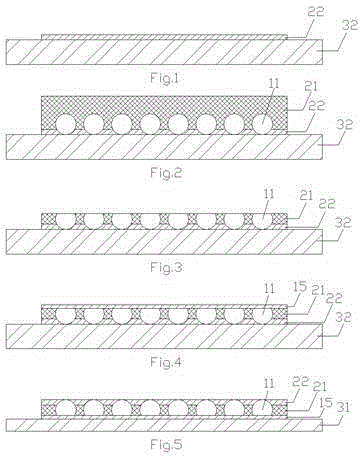

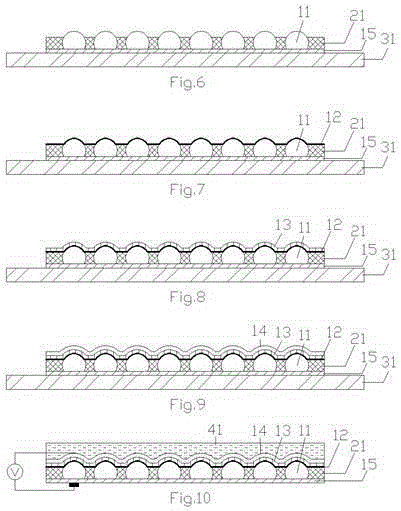

Image

Examples

Embodiment 1

[0049] This embodiment is to use CZTS single crystal particles to prepare solar cells, including the following steps:

[0050] (1) Preparation of CZTS single crystal particles:

[0051] 1. Preparation of Cu by hydrothermal method 2 ZnSnS 4 Nanoparticles: 2mmol CuCl 2 2H 2 O, 1mmol ZnCl 2 , 1mmolSnCl 4 ·5H 2 O was dissolved in 30mL deionized water and stirred for 10min to obtain clear solution A; 5mmol thiourea was dissolved in 20ml deionized water and stirred for 10min to obtain clear solution B; solution B was slowly added to solution A under stirring to obtain white turbidity solution, stirred for 10min to obtain a mixed solution, moved the mixed solution into a 100ml polytetrafluoroethylene autoclave and placed the autoclave at 180°C for 16h, cooled to room temperature and centrifuged at 8000r / min with deionized water and absolute ethanol respectively Separate and dry at 60°C for 8 hours to obtain a black sample, namely CZTS nanoparticles.

[0052] 2. Preparation of...

Embodiment 2

[0067] The experimental method is the same as in Example 1, the only difference is the preparation of CZTS single crystal particles, including the following steps:

[0068] 1. Preparation of Cu by hydrothermal method 2 ZnSnS 4 Nanoparticles: the same as in Example 1.

[0069] 2. Weigh the reaction raw materials 18mmolCuS, 12mmolZnS, 10mmolSn powder, 10mmolS powder and flux 50mmolCsCl, and add 1mmolCZTS nanoparticles to mix and grind thoroughly to make it mix evenly; put the mixed sample after grinding evenly into a quartz bottle, pass three The through valve is vacuumed by the vacuum pump unit to reach 10-10 2 Pa (can also be protected with inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with mixed samples in an ordinary heating furnace to heat from normal temperature to 850 Keep the temperature at ℃ for 72 hours, then cool down to about 600℃, take out the quart...

Embodiment 3

[0071] The experimental method is the same as in Example 1, the only difference is the preparation of CZTS single crystal particles, including the following steps:

[0072] 1. Preparation of Cu by hydrothermal method 2 ZnSnS 4 Nanoparticles: the same as in Example 1.

[0073] 2. Weigh the reaction raw materials 18mmolCu, 12mmolZn, 10mmolSn powder, 40mmolS powder and flux 80mmolCsCl, and add 2mmolCZTS nanoparticles to mix and grind fully to make it mix evenly; put the mixed sample after grinding evenly into a quartz bottle, pass three The through valve is vacuumed by the vacuum pump unit to reach 10-10 2 Pa (can also be protected with inert gas), so as to eliminate the influence of air on the molten salt reaction, seal the quartz bottle with an oxyhydrogen flame; place the sealed quartz bottle with mixed samples in an ordinary heating furnace to heat from normal temperature to 850 Keep the temperature at ℃ for 72 hours, then cool down to about 600℃, take out the quartz bottle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com