Dialysate adsorbing filler, preparation method and application of dialysate adsorbing filler

A technology for adsorbing fillers and dialysate, applied in dialysis systems, chemical instruments and methods, and adsorbed water/sewage treatment, etc., can solve problems such as complex pipelines, heavy burden on microporous membranes or filters, and high frequency of membrane replacement. The effect of risk reduction, risk reduction and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 hot melt adhesive solid material compound

[0043] The preparation steps are:

[0044] 1) Add 20 mg of gelatin to 20 mL of water, heat and dissolve to obtain a clear aqueous solution;

[0045] 2) Keep the temperature of the gelatin aqueous solution above 50°C, add zirconium phosphate solid powder into the gelatin aqueous solution, the mass ratio of gelatin and solid material is 1:400, stir for 1 hour,

[0046] 3) Keep stirring, cool to room temperature, collect solids, wash with deionized water, and dry.

[0047] The obtained solid is the composite material of zirconium phosphate and gelatin.

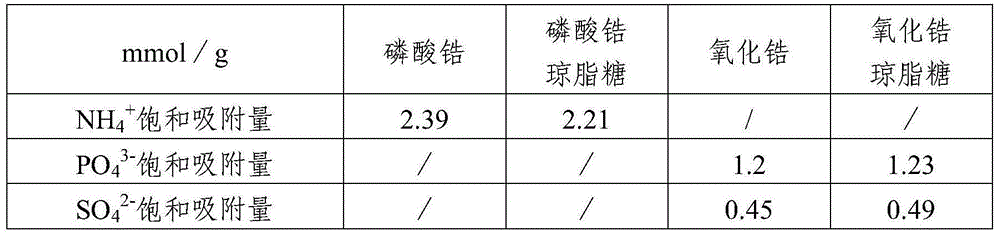

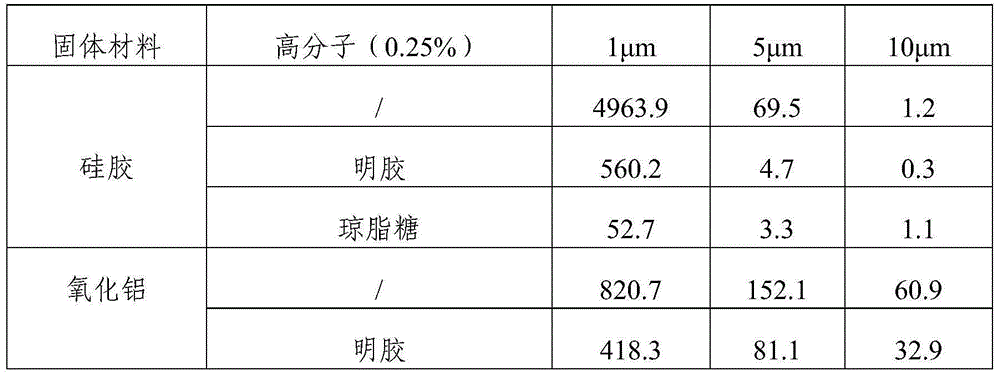

[0048] Using the same method, other kinds of composite adsorption materials were prepared respectively. The polymer is: agar powder, agarose, carrageenan, guar gum, pectin, safflower gum, tragacanth gum, konjac powder, polyvinyl alcohol and other hot sols or a combination of several; the solid material is: Zirconia, Zirconium Carbonate, Magnesi...

Embodiment 2

[0049] Embodiment 2pH adjusts the preparation of hydrogel solid material composite

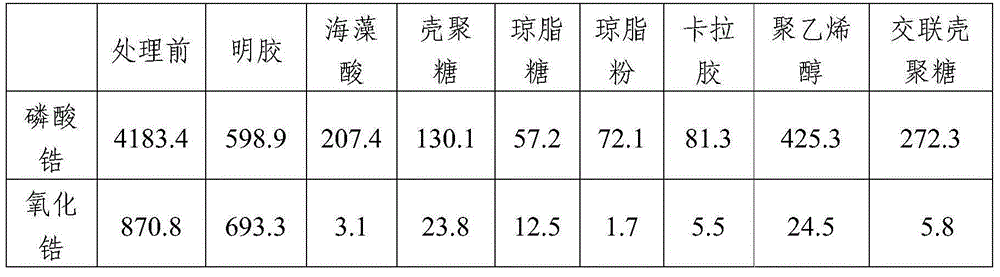

[0050] Dissolve 20mg of sodium alginate in 20mL of water, add 20g of zirconium phosphate to it, stir evenly, slowly add hydrochloric acid dropwise, adjust the pH value of the solution to 3, keep stirring for 1 hour, filter, and wash with deionized water until neutral , collecting the solid to obtain a composite adsorption material of zirconium phosphate and alginic acid.

[0051] Using the same method, other kinds of composite adsorption materials were prepared respectively. Polymer materials are: potassium alginate, ammonium alginate, hyaluronic acid, carboxymethyl cellulose, carboxymethyl chitosan, polyacrylic acid and its salt derivatives; solid materials: zirconium oxide, zirconium carbonate, phosphoric acid Magnesium, alumina, titanium oxide, silica gel, diatomaceous earth, montmorillonite and activated carbon.

Embodiment 3

[0052] Embodiment 3 Preparation of amino-containing hydrogel and solid composite material

[0053] Take 20mg of chitosan and dissolve in 20mL of acetic acid aqueous solution (2%, v / v), add 20g of zirconium phosphate therein, after stirring evenly, slowly add sodium carbonate aqueous solution dropwise, adjust the pH value of the solution to 9.5, keep stirring for 1 hour , filtered, washed with deionized water, and the solid was collected to obtain a composite material of chitosan and zirconium phosphate.

[0054] Using the same method, other chitosan composite adsorption materials were prepared respectively. Solid materials: zirconia, zirconium carbonate, magnesium phosphate, aluminum oxide, titanium oxide, silica gel, diatomaceous earth, montmorillonite and activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com