Preparation of three-dimensional graphene manganese dioxide nano-composite modified electrode and capacitive property test method thereof

A nanocomposite material, manganese dioxide technology, applied in the field of composite electrode preparation for supercapacitors, can solve problems such as difficult commercialization, and achieve the effect of overcoming poor electrical conductivity, good electrical conductivity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Accurately weigh 1.6 grams of graphite powder and 0.8 grams of HPPF with an electronic balance 6 , the weighed graphite powder and HPPF 6 Put it in an agate mortar and grind it evenly to get the ionic liquid modified carbon paste, then slowly fill the ionic liquid modified carbon paste into a glass tube with a length of 6cm and an inner diameter of 4mm for compaction, and insert a thin copper wire as a wire , to obtain ionic liquid modified carbon paste electrode (CILE), which was polished to a mirror surface on clean vulcanized paper before use.

Embodiment 2

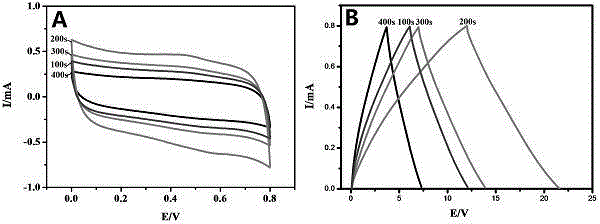

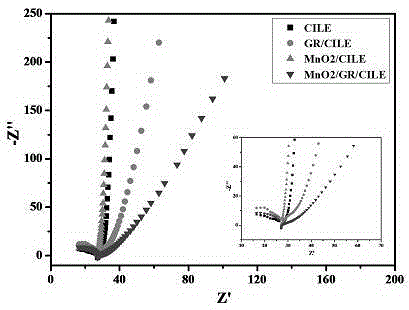

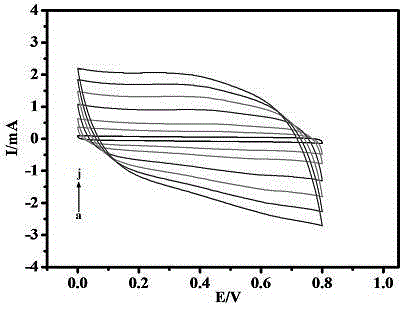

[0033] Accurately weigh 5mg, 10mg, 15mg, 20mg, 25mg, 30mg, 35mg, 40mg, 45mg, 50mg graphite oxide powder (GO) and 1×10 -3 mol lithium perchlorate (Li(ClO 4 )) were mixed separately and dissolved in 10ml double-distilled water, ultrasonically dispersed evenly, the rate of nitrogen passing through the solution was 20ml / min~50ml / min, and the nitrogen passing time was 30min~40min. solution as electrolyte. Using the CILE electrode as the working electrode, the platinum sheet as the auxiliary electrode, and the saturated calomel electrode as the reference electrode, three-dimensional graphene was obtained on the surface of the CILE electrode by using the method of constant potential reduction of graphite oxide powder, and the deposition potential was -1.3V (vs.SCE) , deposition time 300s, optimize graphite oxide powder (GO) and lithium perchlorate (Li(ClO 4 )) Concentration ratio, it was found that 30mgGO and 1×10 -3 molLi(ClO 4 ) ratio is the best. At this time, a layer of grap...

Embodiment 3

[0035] Accurately weigh 30mgGO and 1×10 -3 molLi(ClO 4 ) dissolved in 10ml double-distilled water, ultrasonically dispersed evenly, the rate of nitrogen passing is 20ml / min-50ml / min, the time of nitrogen passing is 30min-40min, and the mixed solution is used as the electrolyte. Using the CILE electrode as the working electrode, the platinum sheet as the auxiliary electrode, and the saturated calomel electrode as the reference electrode, three-dimensional graphene was obtained on the surface of the CILE electrode by using the method of constant potential reduction of graphite oxide powder, and the deposition potential was -1.0V (vs. SCE), -1.1V(vs.SCE), -1.2V(vs.SCE), -1.3V(vs.SCE), -1.4V(vs.SCE), -1.5V(vs.SCE), deposition time 300s, it was found that the three-dimensional graphene obtained by electrochemical deposition had the best effect when the deposition potential was -1.3V (vs. SCE).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com