Molybdenum disulfide / silicon heterojunction solar energy cell and preparation method thereof

A technology of solar cells and molybdenum disulfide, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as difficulties, inability to meet large-scale promotion and application, and high cost, and achieve low cost, good application prospects, and high The effect of crystallization properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

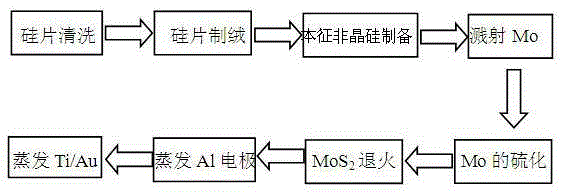

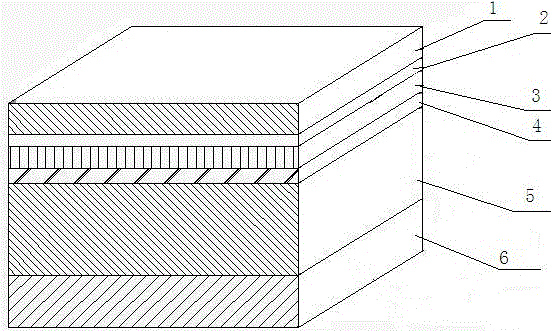

[0033] MoS of the present invention 2 / A method for preparing a Si heterojunction solar cell, comprising the following steps:

[0034] (1) Use acetone solution to ultrasonically clean the single crystal silicon wafer to remove organic dirt on the surface of the silicon wafer, and use alcohol to carry out ultrasonic cleaning to the silicon wafer to remove the acetone on the surface of the silicon wafer, and rinse with deionized water for 3 times , in which the thickness of the monocrystalline silicon wafer is 150 microns to 300 microns, and the resistivity is 0.2Ω·㎝~1.0Ω·㎝;

[0035] (2) Using NH 4 F, the HF mixed solution is used to clean the above-mentioned silicon wafer at normal temperature to remove the surface oxide layer, and then rinse it in deionized water. Wherein the concentration of the ammonium fluoride solution is 35wt%~45wt%, the concentration of the hydrofluoric acid solution is 45wt%~55wt%, and the cleaned single crystal silicon wafer is recorded as single c...

example 1

[0050] (1) Complete the basic etching and cleaning of single crystal silicon wafers according to the above scheme, in which the thickness of the silicon wafer is 150 μm, and the resistivity is 0.2Ω·cm;

[0051] (2) SiH is introduced into the PECVD system 4 , flow 30sccm, pressure 80Pa, time 2min, power 80W;

[0052] (3) Magnetron sputtering system pre-evacuation 3.5×10 -4 Pa, high-purity Ar is introduced at 20 sccm, and the pressure of the vacuum chamber is maintained at 0.5 Pa;

[0053] (4) After pre-sputtering, sputter target Mo onto the above-mentioned silicon wafer with a thin layer of amorphous silicon, adjust the sputtering power to 150W, and the sputtering time to 2min;

[0054] (5) When S reacts with metal Mo, the quartz tube is slowly heated to 750°C, kept at a constant temperature for 10 minutes and then cooled;

[0055] (6) Reaction to produce MoS 2 Anneal at 950°C for 0.5h;

[0056] (7) MoS attached on the upper layer 2 Thermally evaporated Al electrode on th...

example 2

[0059] (1) Complete the etching and cleaning of single crystal silicon wafers according to the above scheme, wherein the thickness of silicon wafers is 200 μm, and the resistivity is 0.5Ω·cm;

[0060] (2) SiH is introduced into the PECVD system 4 , flow 40sccm, pressure 85Pa, time 3min, power 100W;

[0061] (3) Pre-vacuumize the magnetron sputtering system 3.7×10 -4 Pa, high-purity Ar is introduced at 20 sccm, and the pressure of the vacuum chamber is maintained at 0.8 Pa;

[0062] (4) After pre-sputtering, sputter the target material to Mo onto the above-mentioned silicon wafer with a thin layer of amorphous silicon, adjust the sputtering power to 180W, and the sputtering time to 3min;

[0063] (5) When S reacts with metal Mo, the quartz tube is slowly heated to 825°C, kept at constant temperature for 15 minutes and then cooled;

[0064] (6) Reaction to produce MoS 2 Anneal at 1000°C for 0.75h;

[0065] (7) MoS attached on the upper layer 2 Thermally evaporated Al elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com