Method of preparing hydroxyapatite by mechanochemical method

A mechanochemical method and hydroxyapatite technology, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve problems such as unsuitability for industrial production, impact on purity, long heat treatment time, etc., and achieve easy large-scale industrialization Effects of production, improvement of crystallinity and purity, and reduction of reaction activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

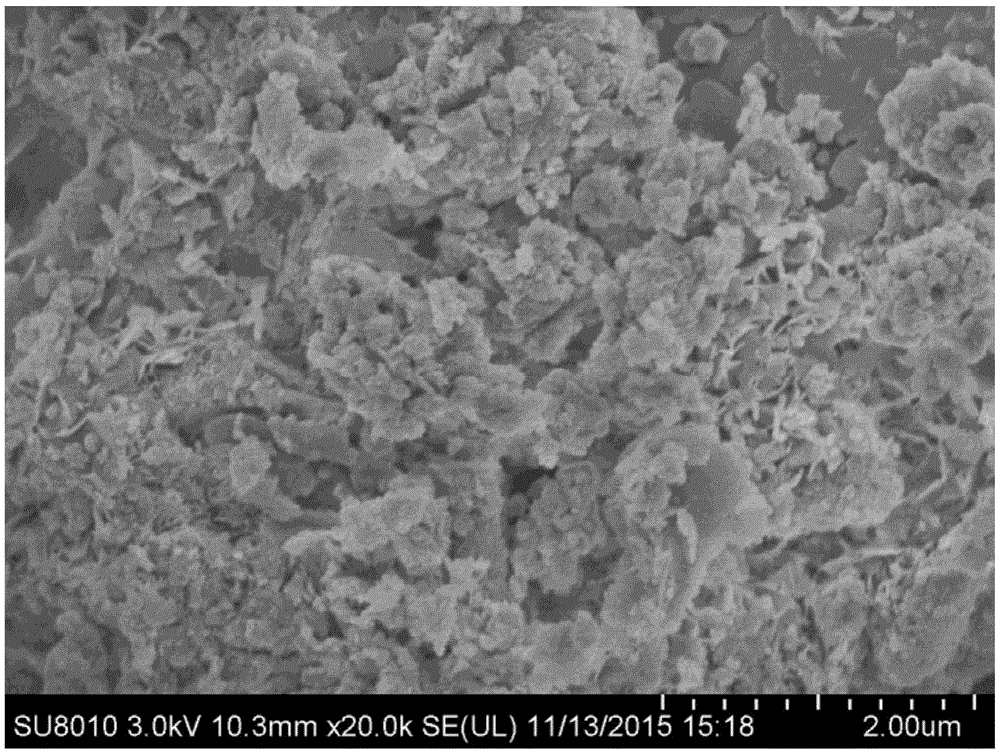

[0019] 1) Put 100g of scallop shells and 124.2g of anhydrous disodium hydrogen phosphate into a planetary ball mill according to the molar ratio of Ca / P=1, set the speed of the ball mill to 100r / min, and the ball milling time to 30h. 2) After the reaction is over, mix 200g of the mixture with 6000g of water, and feed high-purity CO 2 Gas, react for 120min; or transfer 200g of the mixture and 6000g of water into the reactor, set the reaction temperature to 50°C, and the reaction time to 30h. After the reaction, filter and dry to obtain hydroxyapatite powder. Scanning electron microscopy of hydroxyapatite figure 1 shown.

Embodiment 2

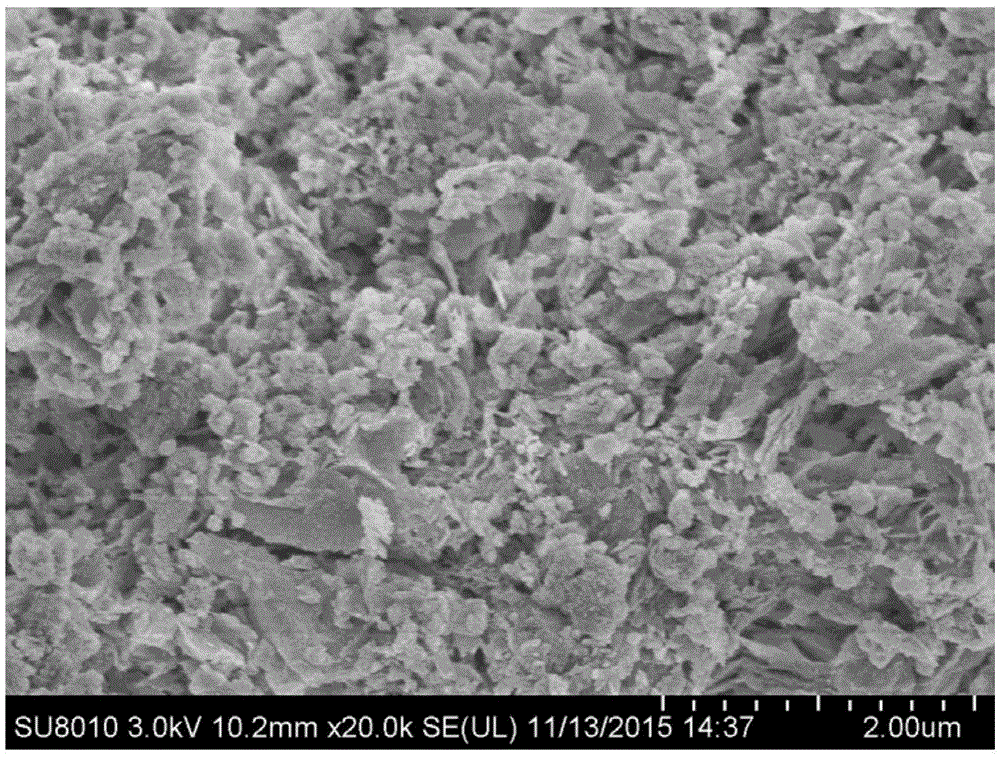

[0021] 1) Put 100g of oyster shells and 71.9g of anhydrous sodium dihydrogen phosphate into a stirring ball mill according to the molar ratio of Ca / P=1.5, set the speed of the ball mill to 600r / min, and the ball milling time to 6h. 2) After the reaction is over, mix 150g of the mixture with 750g of water, and feed high-purity CO 2 Gas, react for 20 minutes; or transfer 150g of the mixture and 750g of water into the reactor, set the reaction temperature to 150°C, and the reaction time to 5h. After the reaction, filter and dry to obtain hydroxyapatite powder. Scanning electron microscopy of hydroxyapatite figure 2 shown.

Embodiment 3

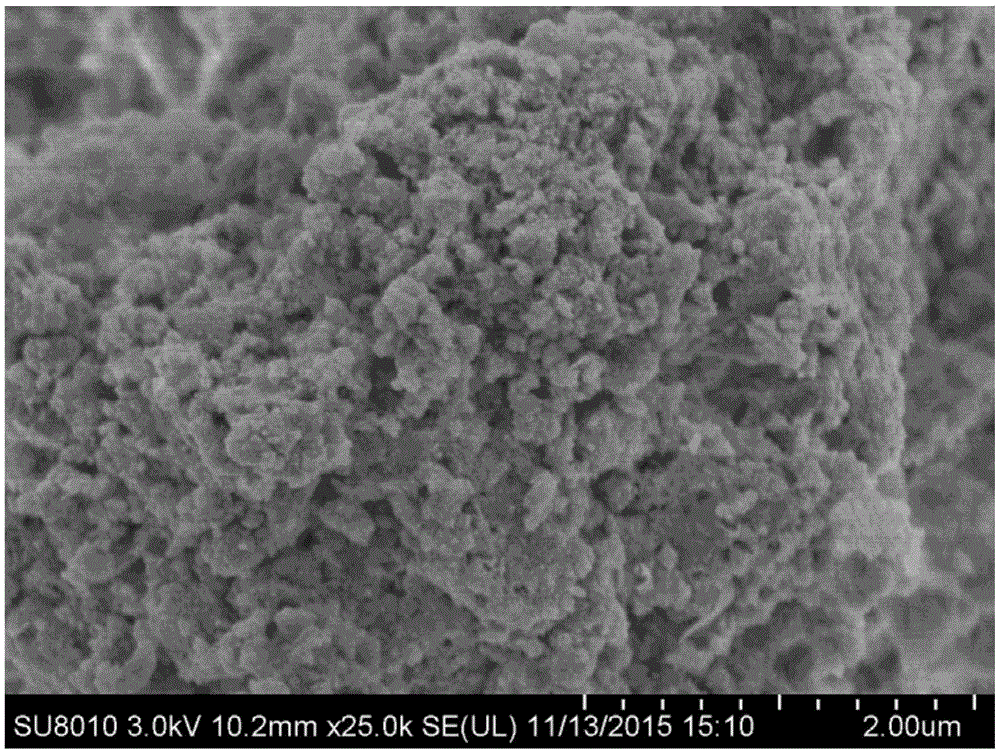

[0023] 1) Put 100g of mussel shells and 61.1g of diamine hydrogen phosphate into a stirring ball mill according to the molar ratio of Ca / P=2, set the speed of the ball mill to 200r / min, and the ball milling time to 25h. 2) After the reaction is over, mix 150g of the mixture with 1500g of water, and feed high-purity CO 2 Gas, react for 30 minutes; or transfer 150g of the mixture and 1500g of water into the reactor, set the reaction temperature to 60°C, and the reaction time to 26h. After the reaction, filter and dry to obtain hydroxyapatite powder. Scanning electron microscopy of hydroxyapatite image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com