Biologically-enhanced treatment method for cyanide-containing chemical wastewater

A bio-augmentation and chemical wastewater technology, applied in the field of water treatment, can solve the problems of secondary pollution and high treatment costs, and achieve the effects of reducing treatment costs, wide application prospects, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

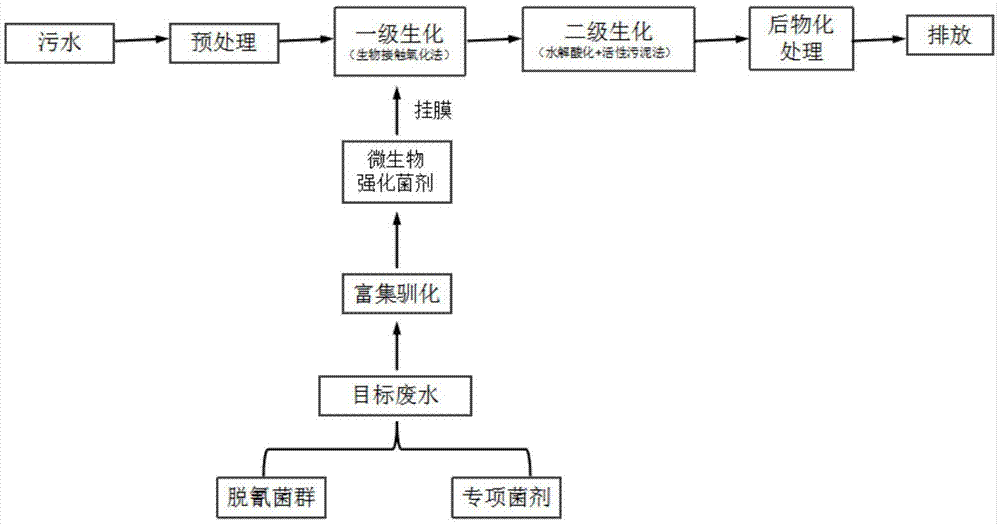

Method used

Image

Examples

preparation example Construction

[0041] Next, the filler is prepared, that is, the film-forming filler is hung on a shelf, and placed in the primary reaction pool to be formed. The film-hanging filler chooses a combination of fillers, that is, the aldehyde fiber or polyester yarn is pressed on the double-circle large plastic ring, so that the fiber bundles are evenly distributed, so that the inner ring is a snowflake-shaped plastic branch, which can not only hang the film, but also effectively cut the air bubbles, improving The transfer rate and utilization rate of oxygen enable the water-air biofilm to be fully exchanged and the organic matter in the water to be treated efficiently. The unit diameter is Φ150mm, the spacing is 80mm, and each cubic meter contains 100 units.

[0042] Next, the above nutrient solution is added to the primary biochemical reaction tank, and then the fermentation bacteria solution is added, mixed evenly, and then expanded and cultivated in an aerobic state for 2-3 days. Wherein, th...

Embodiment 1

[0046] A pigment company in Shandong produces wastewater with a cyanide concentration of 178mg / L, a COD concentration of 526.96mg / L, and a salinity of 4.6%. Due to the high salt content of the water, some salt-tolerant bacteria were added, and the high-salt decyanation-resistant bacteria group was domesticated by gradually increasing the salinity, and the microbial enhanced bacterial agent was obtained, and the film was hanged in the first-level biochemical reaction tank. Treat and inoculate it. The water is first pretreated by flocculation and sedimentation to remove part of the salt and reduce biochemical pressure. The water is decyanated in the first bioreactor with the addition of glucose as a nutrient. After decyanation treatment, the secondary biochemical reaction is carried out through hydrolysis acidification and activated sludge treatment. At this time, the concentration of cyanide in the effluent is 5mg / L, and the COD is about 200-300. Therefore, ozone is used to t...

Embodiment 2

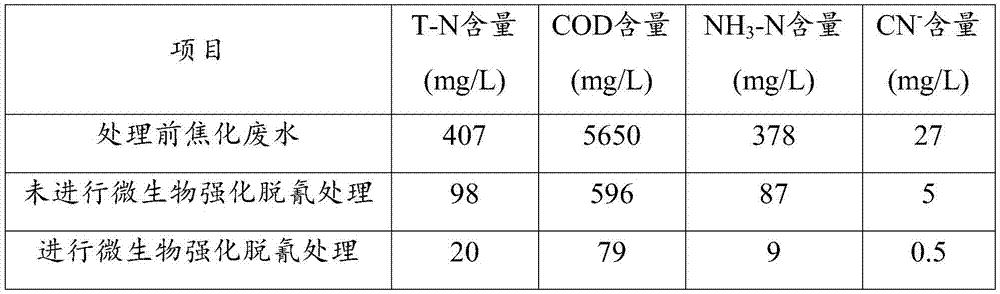

[0048] The wastewater composition of a coking plant is T-N content 410mg / L, COD content 5650mg / L, NH 3 The -N content is 378mg / L, and the cyanide concentration is 43mg / L. Through the analysis of water quality, it was found that the wastewater contained organic substances such as pyridine, quinoline, phenol, o-cresol, naphthalene and n-hexadecane. Bacteria, quinoline-degrading bacteria, phenol-degrading bacteria, o-cresol-degrading bacteria, naphthalene-degrading bacteria and n-hexadecane-degrading bacteria (for details, see another application number of the applicant is 201410833844.4 patent application), forming a composite bacterial agent, in the Enrichment and domestication are carried out in the coking wastewater to obtain the microorganism-enhanced bacterial agent of the wastewater, and the above-mentioned method is carried out to form a film, and inoculated in the first biochemical reaction tank.

[0049] The water is firstly pretreated by the air flotation grease trap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com