Stannous sulfide and indium sulfide thin film solar cell and preparation method thereof

A technology of solar cells and tin sulfide, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high cost and fragility of ITO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

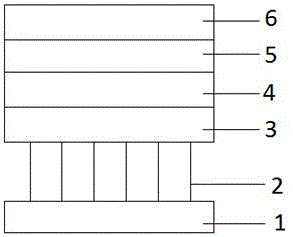

Image

Examples

Embodiment 1

[0020] First, copper nanowires were deposited on a glass substrate by direct current electrochemical deposition, and the electrolyte was composed of copper sulfate (CuSO 4 ) (90g / L) and boric acid (H 3 BO 3 ) (45g / L) aqueous solution, then add 1M sulfuric acid (H 2 SO 4 ) solution to adjust the pH to be PH=2.5. Electrodeposition conditions are: applied DC voltage 0.2V, deposition temperature is 25°C (room temperature), and deposition time is 90 minutes; Deposition β—In 2 S 3 film. The sputtering power is 120W, the vulcanization heat treatment temperature is 450°C, the sputtering gas pressure is 0.5Pa, and the sputtering time is 6min; thirdly, in a vacuum environment, using molybdenum metal particles and sulfur powder as raw materials, using the dual-source evaporation method In β-In 2 S 3 Molybdenum disulfide (MoS) deposited on the film 2 ) film, by adjusting the size of the electron beam for molybdenum metal evaporation, the temperature of sulfur powder evaporation,...

Embodiment 2

[0022] First, silver metal nanowires were deposited on a silicon wafer substrate by direct current electrochemical deposition. The electrolyte consists of silver nitrate (AgNO 3 ) (45g / L) and boric acid (H 3 BO 3 ) (45g / L) aqueous solution, then add 1M nitric acid (HNO 3 ) solution adjustment pH value is PH=2.3. The electrodeposition conditions are: an external DC voltage of 0.2V, a deposition temperature of 25°C (room temperature), and a deposition time of 30 minutes; second, the deposition of N-type β-In on silver metal nanowires by ultrasonic spraying 2 S 3 Thin film, using indium chloride (InCl 3 4H 2 O) and thiourea as indium (In) source and sulfur (S) source, prepare 50ml solution according to In / S molar concentration ratio 1:5, take the molar concentration of In ion as 60mmol / L, atomize through piezoelectric ceramic chip The prepared solution is atomized by the device, the atomization rate is 100ml / h, the flow rate of high-purity nitrogen gas is controlled at 5L / ...

Embodiment 3

[0024] First, nickel metal nanowires were deposited on organic flexible plastic substrates by direct current electrochemical deposition. The electrolyte is nickel sulfate (NiSO 4 ·6H 2 O) (100g / L), nickel chloride (NiCl 2 ·6H 2 O) (20g / L) and H3 BO 3 (45g / L) aqueous solution, then add 1M H 2 SO 4 The pH of the solution was adjusted to PH=2.5. Electrodeposition conditions are: DC voltage 0.2V applied, deposition temperature 25°C (room temperature), and deposition time 240 minutes; secondly, magnetron sputtering is used to prefabricate In thin film and vulcanization heat treatment process to deposit β— In 2 S 3 film. The sputtering power is 120W, the vulcanization heat treatment temperature is 450°C, the sputtering gas pressure is 0.5Pa, and the sputtering time is 6min; thirdly, in a vacuum environment, using molybdenum metal particles and sulfur powder as raw materials, using the dual-source evaporation method In N-type β-In 2 S 3 Depositing MoS on thin films 2 Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com