High-temperature-resistant organosilicon-amine inhibitor for water-based drilling fluid and preparation method of organosilicon-amine inhibitor

A water-based drilling fluid, high-temperature resistance technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient temperature resistance, adsorption damage, intensified thermal motion, etc., to achieve ideal temperature resistance, guarantee Robust, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

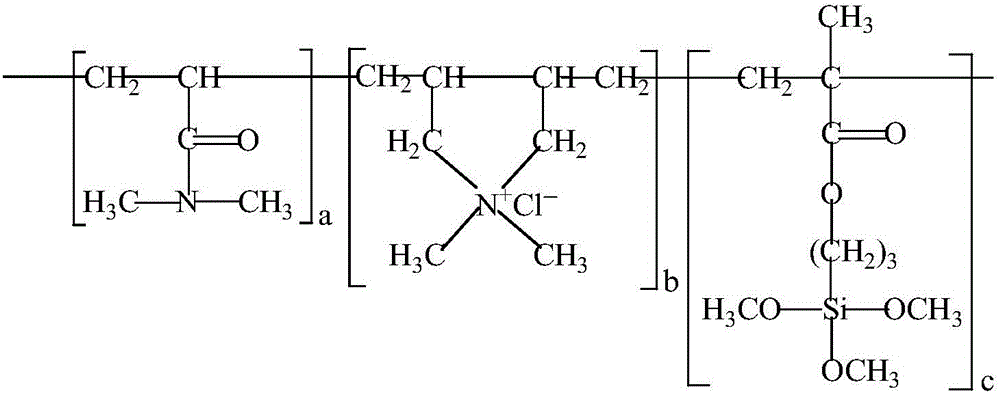

[0027] Preparation of Inhibitor PKDAS

[0028] Accurately weigh 100.0g of N,N-dimethylformamide, pour it into a three-necked flask with a capacity of 500ml, turn on the magnetic stirring, and weigh 15.5g of N,N-dimethylpropionamide, 5.3g of Dimethyl diallyl ammonium chloride and 4.2g of γ-(methacryloyloxy)propyltrimethoxysilane are poured into a three-necked flask filled with DMF, and after it is fully mixed, nitrogen gas is exhausted. Oxygen, be warming up to reaction temperature, and after logical nitrogen 30 minutes, add the initiator azobisisobutyronitrile of 0.1g, obtain powdery white gel-like product after 8 hours reaction under logical nitrogen condition, it is taken out and Soak in excess benzene, let it stand for 24 hours, filter and separate it with a Soxhlet extractor, soak the insoluble components in excess absolute ethanol for 12 hours, then carry out vacuum filtration, collect the insoluble components on the filter paper and then vacuum them Dried and pulverized...

Embodiment 2

[0031] Structural characterization of the inhibitor PKDAS

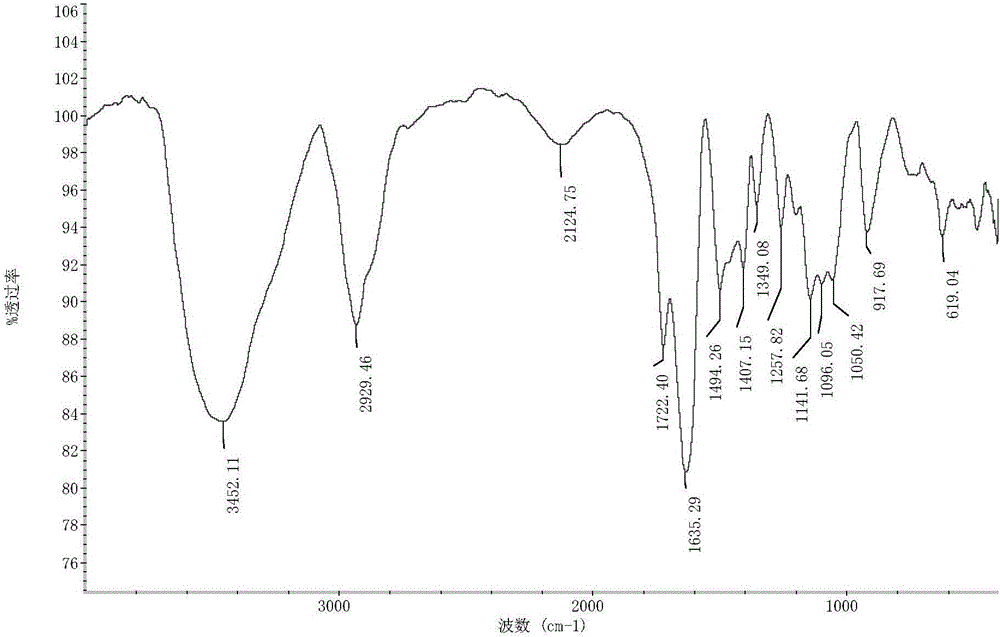

[0032] see figure 1 , figure 1 It is the infrared absorption spectrogram of inhibitor PKDAS, and its characteristic absorption peak analysis of the spectrum is as follows:

[0033] 3452cm -1 The place is the C=O bond stretching vibration absorption peak in the KH-570 ester group; 2929cm -1 In the main chain of the copolymer molecule -CH 2 - stretching vibration peak; 2124cm -1 The place is -N-CH in the structural unit of DMAA and DMDAAC 3 The absorption peak; 1722cm -1 The place is the C=O bending vibration absorption peak of DMAA primary amide group; 1635cm -1 It is the C=O bond stretching vibration absorption peak in the DMAA tertiary amide group; 1494cm -1 The peak is the C-N bond stretching vibration peak in DMAA; 1407cm -1 The -CH of the siloxane group in KH-570 3 The absorption peak; 1349cm -1 N-CH in DMAA 3 The characteristic absorption peak; 1257cm -1 The place is the C=O bond stretching vibration...

Embodiment 3

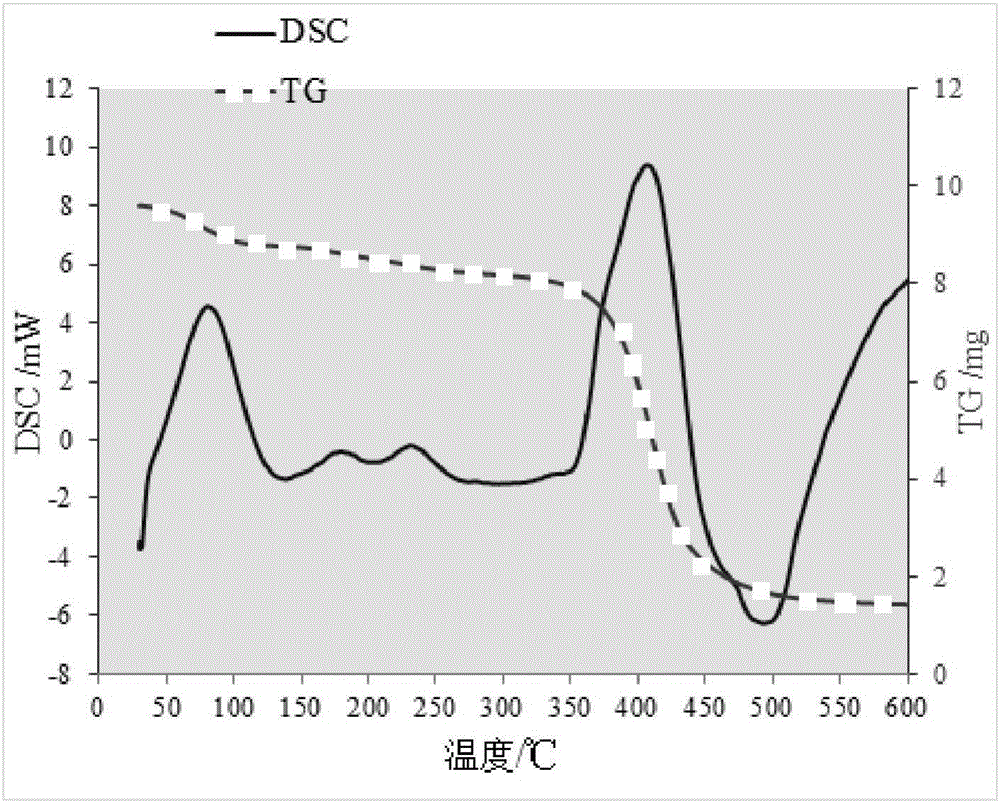

[0036] Thermogravimetry-differential calorimetry (TG-DSC) analysis of inhibitor PKDAS

[0037] see figure 2 , figure 2 is the thermogravimetric-differential thermal analysis diagram of the inhibitor PKDAS, obtained by figure 2 It can be seen that the thermal degradation process of PKDAS can be divided into four stages according to its temperature range:

[0038] (1) Temperature range: 25.00℃~182.31℃

[0039]The TG curve in this temperature range gradually decreases, indicating that the mass of the sample decreases due to heating, and its weight loss percentage is 11.27%, while the DSC curve first rises and then declines, forming a gentle endotherm after forming a steep exothermic peak peak. This is because the siloxane groups in the molecular structure of the sample are hydrolyzed to form silanol groups due to water absorption and moisture, and the latter undergo condensation reactions with each other and a large amount of heat is released, resulting in an exothermic pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com