Method and system for recovering fluorine from waste acid produced in thinning production of solar cells or glass

A technology for thinning solar cells and glass, applied in energy and wastewater treatment, chemical instruments and methods, multi-stage water treatment, etc. Low fluoride content and other problems, to achieve the effect of facilitating large-scale automatic continuous operation, reducing the volume and quantity of equipment, and reducing the degree of fluorine pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

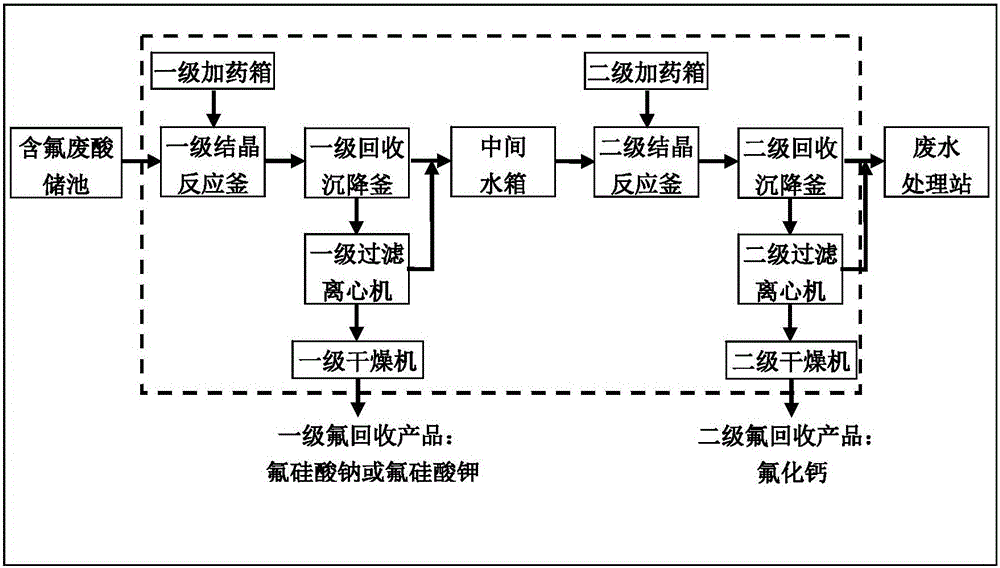

Method used

Image

Examples

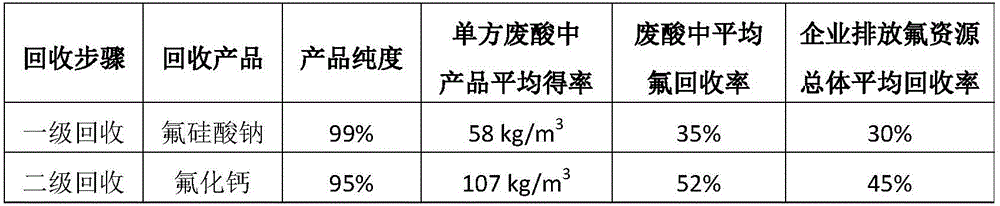

Embodiment 1

[0040] This embodiment is applied to a polysilicon solar cell production enterprise with a production capacity of 900MW / a, including 30 cell production lines.

[0041] The fluorine recovery method of the present embodiment comprises the following steps:

[0042] 1) The production line adopts source separation and discharge, and the collection of fluorine-containing waste acid mainly comes from: acid velvet bath bath (main production raw materials include hydrofluoric acid and nitric acid), pickling bath bath (main raw materials include hydrofluoric acid and Hydrochloric acid) and acid etching bath bath (main raw materials include hydrofluoric acid and nitric acid, etc.). The company is in full production, and the total amount of fluorine-containing waste acid collected daily is about 40m 3 / d, where the fluorine ion concentration is 60–120g / L, and fluorine in fluorine-containing waste acid accounts for about 86% of the total fluorine resources discharged by the enterprise.

...

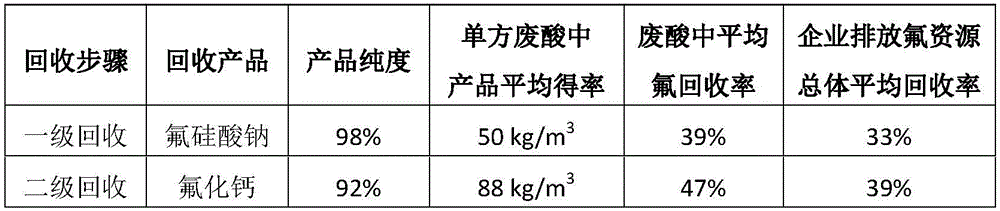

Embodiment 2

[0057] This embodiment is applied to a medium-sized glass thinning production enterprise, and the fluorine recovery method includes the following steps:

[0058] 1) Collect about 15m of fluorine-containing waste acid 3 / d, mainly comes from pickling tank liquid (the main raw material includes hydrofluoric acid), in which the average concentration of fluorine ions is 82g / L, and fluorine in fluorine-containing waste acid accounts for about 83% of the total fluorine resources discharged by the enterprise.

[0059] 2) Add sodium salt to the fluorine-containing waste acid collected in step 1 to form a crystalline precipitate, then separate, wash and dry to generate sodium fluorosilicate product and recover fluorine resources; the specific implementation includes:

[0060] 2-1) Add sodium salt in the collected waste acid, the sodium salt adopts sodium nitrate, i.e. sodium nitrate, the average amount is about 98g / L, the amount of sodium in the present embodiment is related to the qua...

Embodiment 3

[0072] This embodiment is applied to a monocrystalline silicon solar cell production enterprise, which has 8 monocrystalline silicon cell production lines with an annual production capacity of 480MW / a. The fluorine recovery method comprises the following steps:

[0073] 1) Collect about 10m of fluorine-containing waste acid 3 / d, mainly derived from the pickling bath solution (main raw materials include hydrofluoric acid and hydrochloric acid), acid etching bath solution (including hydrofluoric acid and nitric acid) and etching line pickling bath solution (mainly containing hydrofluoric acid) acid). The average concentration of fluorine ions in fluorine-containing waste acid is 26g / L, and fluorine in fluorine-containing waste acid accounts for about 70% of the total fluorine resources discharged by the enterprise.

[0074] 2) Add potassium salt to the fluorine-containing waste acid collected in step 1 to form a crystalline precipitate, then separate, wash and dry to generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com