Method for preparing solid electrochemical luminescence sensor

A sensor and electrochemical technology, which is applied in the field of preparation of solid-state electrochemiluminescent sensors, can solve the problems of strict raw material requirements, complicated preparation process, and complicated preparation process, and achieve friendly application environment, high preparation efficiency, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

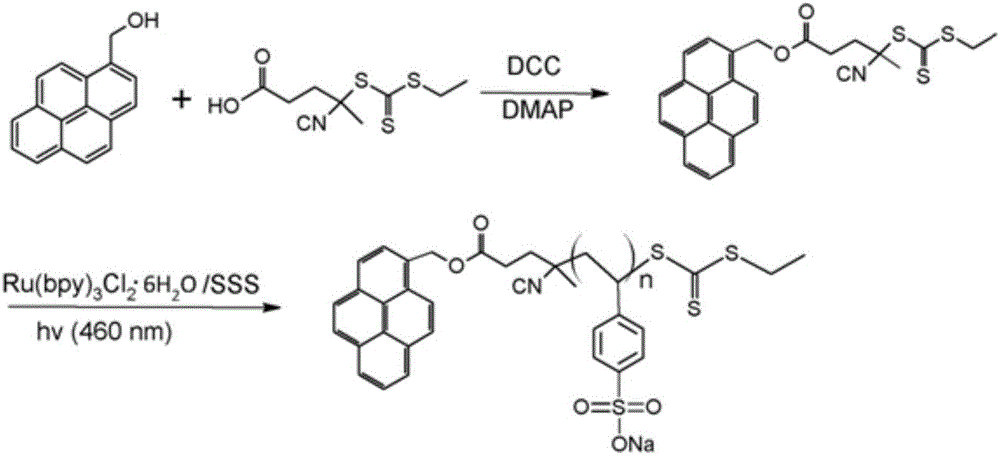

[0037] In this example, 4-cyano-4-ethyltrithiopentanoic acid (CETP) was functionalized with pyrene to obtain pyrene-functionalized pyrene-functionalized 4-cyano-4-ethyltrithiopentanoic acid ( PCETP) reagent, the specific process is:

[0038] (1) Dissolve 0.5g pyrenemethanol, 0.73g CETP, 0.6383g dicyclohexylcarbodiimide (DCC) and 0.0378g 4-dimethylaminopyridine (DMAP) in 10mL tetrahydrofuran (THF) respectively to obtain a mixture;

[0039] (2) The mixture described in step (1) was stirred and reacted at room temperature for 12 hours, and then filtered to remove solid by-products to obtain a filtrate;

[0040] (3) After the filtrate obtained in step (2) is rotary evaporated, the product obtained is PCETP according to the weight ratio of ethyl acetate and n-hexane 30:70 through a silica gel column;

Embodiment 3

[0042] The pyrene-functionalized RAFT reagent is used to illustrate the process of synthesizing pyrene-functionalized PSS through photoinitiated polymerization. The specific process includes the following steps:

[0043] (1) 23.9 mg of RAFT reagent (pyrene-functionalized 4-cyano-4-ethyltrithiopentanoic acid, PCETP), 2.06 g of a negatively charged monomer under neutral pH conditions (p-styrenesulfonic acid Sodium) and 1.5mg terpyridine ruthenium are dissolved in 50mL volumetric flask with 3.5mL water and 3.5mL dioxane to obtain reagent;

[0044] (2) feed nitrogen into the volumetric flask equipped with reagent in step (1) to remove oxygen for 30 minutes;

[0045] (3) irradiate and stir the volumetric flask after deoxygenation in step (2) under a 165W blue light for 24h;

[0046] (4) dialyze the product obtained in step (3) in ultrapure water for 3 days, then put it into a vacuum box and dry it to obtain the polymer PSS;

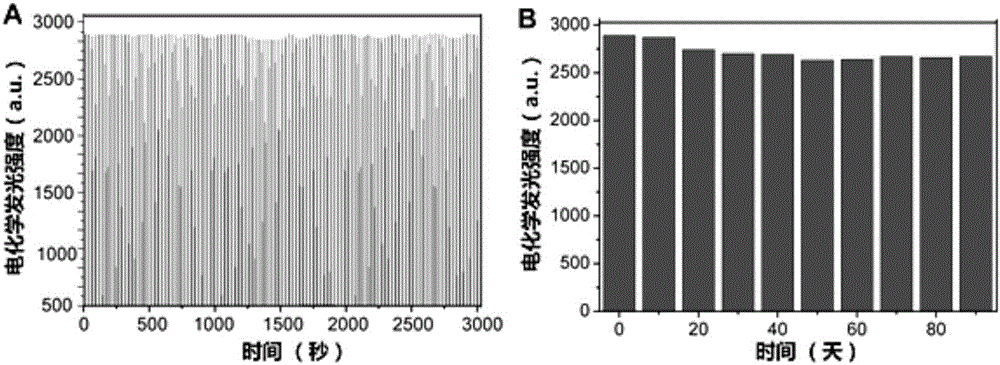

[0047] (5) The PSS synthesized by the above-mentioned ...

Embodiment 4

[0049] PSS1 is dissolved in water to obtain a 5mM PSS1 aqueous solution. The prepared PSS1 aqueous solution is mixed with a cation exchange resin (such as Nafion) at a volume ratio of 1:1, and then directly dripped onto the electrode surface and dried for 60 seconds by infrared to obtain a solid-state electrochemical solution. Luminescence sensor;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com