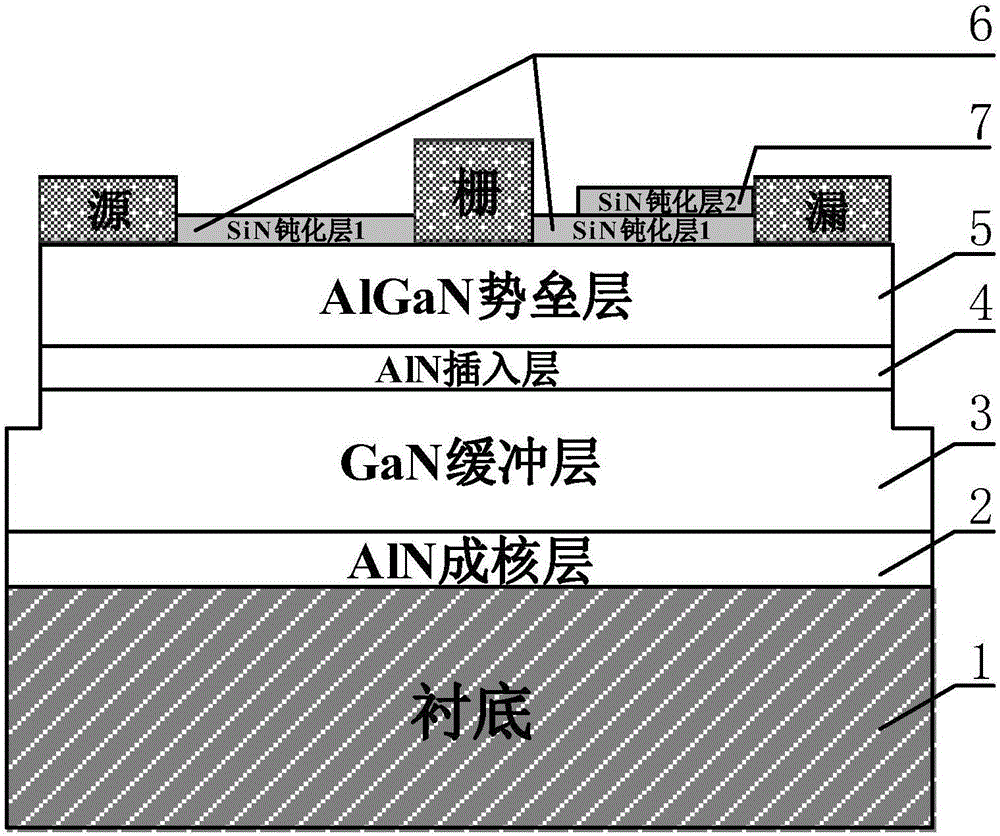

Thin barrier enhanced AlGaN/GaN high-electron-mobility transistor and manufacturing method thereof

A high electron mobility and enhanced technology, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low channel carrier concentration, small transconductance and saturation output current, and poor gate control ability etc. to avoid etching damage and alignment errors, increase saturated output current, and improve breakdown characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

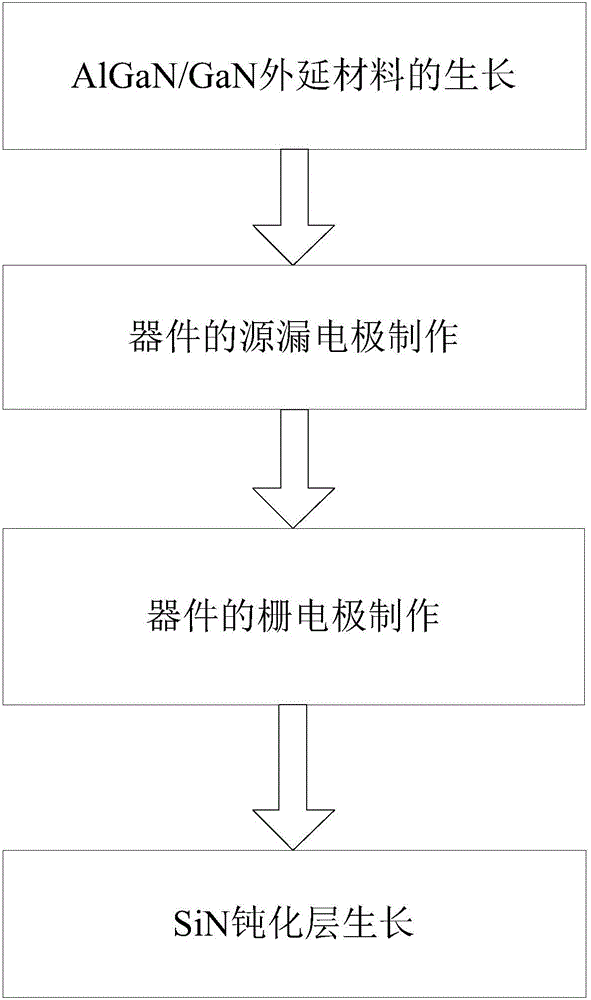

Method used

Image

Examples

Embodiment 1

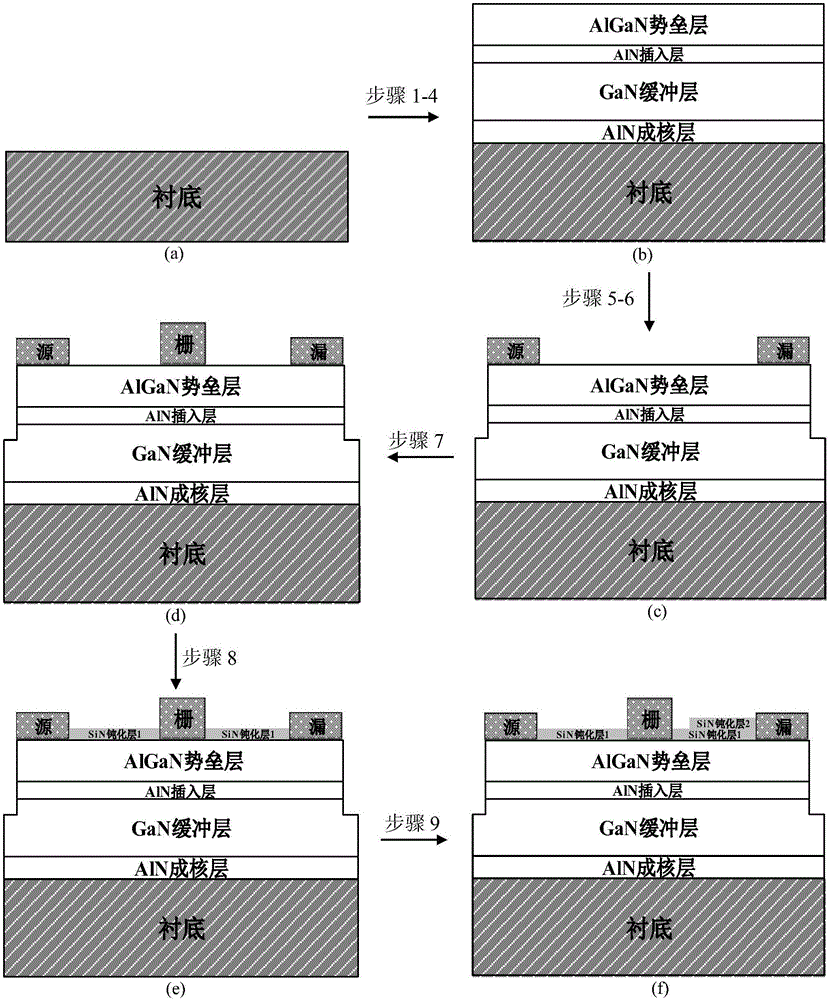

[0039] Example 1, the production substrate is sapphire, the thickness of the first layer of SiN passivation is 2nm, the thickness of the second layer of SiN passivation is 2nm, and the thickness of the AlGaN barrier layer is 3nm. Thin barrier enhanced AlGaN / GaN high electron mobility transistor.

[0040] In step 1, an AlN nucleation layer with a thickness of 20 nm is grown on a sapphire substrate by using a metal oxide chemical vapor deposition (MOCVD) process.

[0041] (1a) Put the sapphire substrate into the reaction chamber of the metal oxide chemical vapor deposition MOCVD equipment; reduce the vacuum degree in the reaction chamber to 1×10 -2 Torr, high-temperature heat treatment and surface nitriding treatment on the sapphire substrate, the treatment conditions are: NH 3 Gas flow rate is 1500sccm, H 2 The gas flow rate is 1500sccm, the heating temperature is 1050°C, the heating time is 5min, and the pressure is maintained at 40Torr;

[0042] (1b) A 20nm thick AlN is gr...

Embodiment 2

[0065] Example 2, the production substrate is SiC, the first layer of SiN passivation thickness is 1.5nm, the second layer of SiN passivation thickness is 2.5nm, and the AlGaN barrier layer thickness is 5nm thin barrier enhanced AlGaN / GaN high electron density Mobility transistor.

[0066] Step 1, growing an AlN nucleation layer on the SiC substrate.

[0067] (1.1) Put the SiC substrate into the reaction chamber of the metal oxide chemical vapor deposition MOCVD equipment; reduce the vacuum degree in the reaction chamber to 1×10 -2 Torr, high-temperature heat treatment and surface nitriding treatment are performed on the SiC substrate, and the treatment conditions are the same as the treatment conditions of step (1a) in embodiment 1.

[0068] (1.2) Deposit and grow AlN with a thickness of 20nm on the SiC substrate as a nucleation layer by metal oxide chemical vapor deposition (MOCVD), and the process conditions are the same as those in step (1b) in Example 1.

[0069] Step 2...

Embodiment 3

[0092] Example 3, the production substrate is sapphire, the thickness of the first layer of SiN passivation is 1nm, the thickness of the second layer of SiN passivation is 3nm, and the thickness of the AlGaN barrier layer is 10nm. Thin barrier enhanced AlGaN / GaN high electron mobility transistor.

[0093] Step A, growing an AlN nucleation layer on the SiC substrate.

[0094] (A1) Put the SiC substrate into the reaction chamber of the metal oxide chemical vapor deposition MOCVD equipment; reduce the vacuum degree in the reaction chamber to 1×10 -2 Torr, high-temperature heat treatment and surface nitriding treatment are performed on the SiC substrate, and the treatment conditions are the same as the treatment conditions of step (1a) in embodiment 1.

[0095] (A2) Deposit and grow AlN with a thickness of 20nm on the SiC substrate as a nucleation layer by metal oxide chemical vapor deposition (MOCVD), and the process conditions are the same as those in step (1b) in Example 1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com