Self-cleaning light-curing anti-fog coating and preparation method thereof

An anti-fog coating and light-curing technology, applied in the coating field, can solve problems such as poor compatibility, affecting coating transparency, and restrictions, and achieve the effects of improving strength and wear resistance, inhibiting the growth of bacteria, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

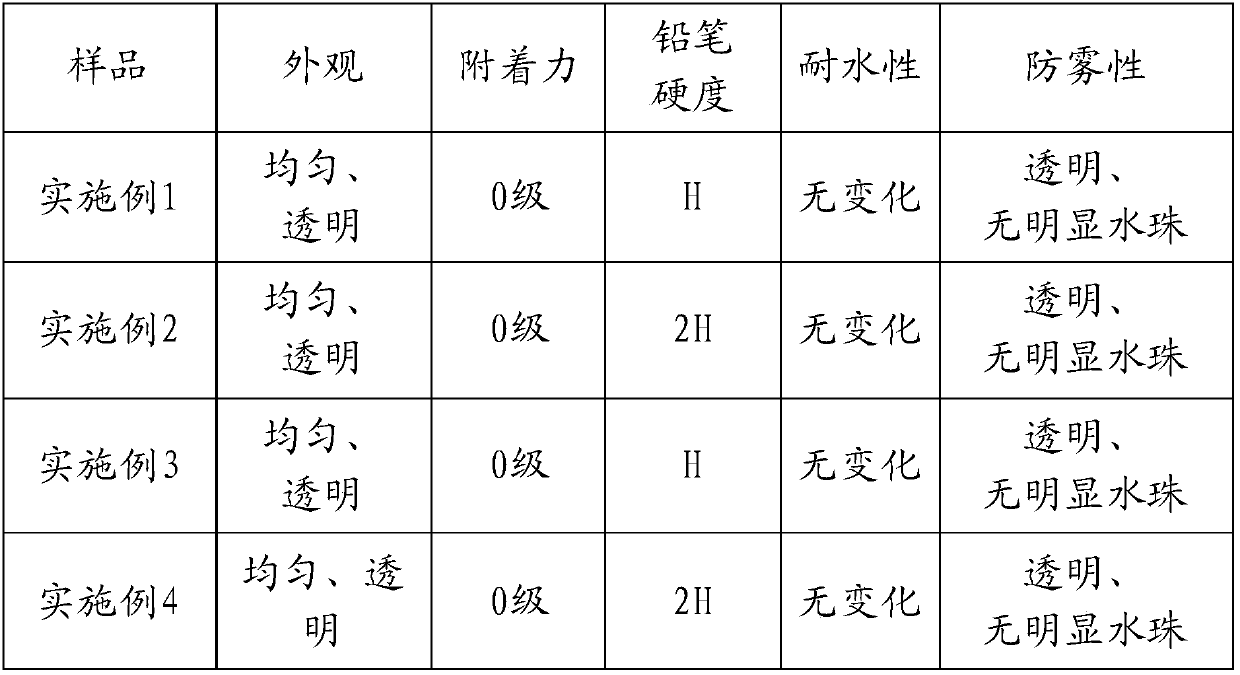

Examples

Embodiment 1

[0032] Ⅰ. Preparation of modified graphene nanoparticles:

[0033] (1) Add 50 parts by mass of allyl glycidyl ether, 6 parts by mass of graphene, 43 parts by mass of ethylene glycol ether, and 1 part by mass of p-phenol polymerization inhibitor into the reaction vessel, ultrasonically disperse for 30 minutes, and stir at 100°C 18 hours, obtain allyl graft modified graphene;

[0034] (2) Add 18 parts by mass of allyl graft modified graphene, 42 parts by mass of acrylate, and 40 parts by mass of ethylene glycol ether into the reaction vessel, and stir for 24 hours at a temperature of 55° C. to obtain modified graphene nanoparticles. particle.

[0035] Ⅱ. Preparation of hydrophilic photosensitive resin:

[0036] 25 parts by mass of 2-acrylamide-2-methyl-propanesulfonic acid, 25 parts by mass of dimethylaminoethyl methacrylate and 15 parts by mass of N, N-dimethylaminoethyl (meth)acrylamide were slowly Add 32 parts by mass to ethylene glycol ether dropwise, add 3 parts by mass ...

Embodiment 2

[0039] Ⅰ. Preparation of modified graphene nanoparticles:

[0040] (1) Add 45 parts by mass of allyl glycidyl ether, 8 parts by mass of graphene, 45 parts by mass of diethylene glycol methyl ether, and 2 parts by mass of p-phenol polymerization inhibitor into the reaction vessel, and ultrasonically disperse for 30min. Stirring at 90°C for 18 hours to obtain allyl grafted modified graphene;

[0041] (2) Add 20 parts by mass of allyl grafted modified graphene, 60 parts by mass of hydroxyethyl methacrylate, and 20 parts by mass of diethylene glycol methyl ether into the reaction vessel, and stir at a temperature of 60°C After 24 hours, modified graphene nanoparticles were obtained.

[0042] Ⅱ. Preparation of hydrophilic photosensitive resin:

[0043] 30 parts by mass of hydroxybutyl methacrylate, 15 parts by mass of dimethylaminoethyl methacrylate and 21 parts by mass of N,N-dimethylacrylamide are slowly added dropwise to 30 parts by mass of diethylene glycol ethyl ether, At 9...

Embodiment 3

[0046] Ⅰ. Preparation of modified graphene nanoparticles:

[0047] (1) Add 55 parts by mass of allyl glycidyl ether, 10 parts by mass of graphene, 33 parts by mass of diethylene glycol ether, and 2 parts by mass of p-phenol polymerization inhibitor into the reaction vessel, ultrasonically disperse for 30min, and Stirring at ℃ for 18 hours to obtain allyl graft modified graphene;

[0048] (2) Add 16 parts by mass of allyl graft modified graphene, 50 parts by mass of hydroxyethyl acrylate, and 34 parts by mass of diethylene glycol ethyl ether into the reaction vessel, and stir for 24 hours at a temperature of 70° C. to obtain Modified graphene nanoparticles.

[0049] Ⅱ. Preparation of hydrophilic photosensitive resin:

[0050] 31 parts by mass of hydroxyethyl acrylate, 15 parts by mass of dimethylaminoethyl methacrylate and 15 parts by mass of N,N-diethylacrylamide were slowly added dropwise to 35 parts by mass of propylene glycol methyl ether, at 90°C, 4 parts by mass of diben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com