Lysozyme with covalent modification through acyl-free sophorolipid derivatives and modifying method and application of lysozyme

A technology of acyl sophorolipids and modification methods, which is applied in the field of food preservation, can solve the problems of limiting the application range of lysozyme, difficulty in dissolving, and inability to effectively inhibit activity, and achieve the expansion of antibacterial spectrum and loss of enzyme activity Small, simple and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of acyl-free sophorolipid derivatives:

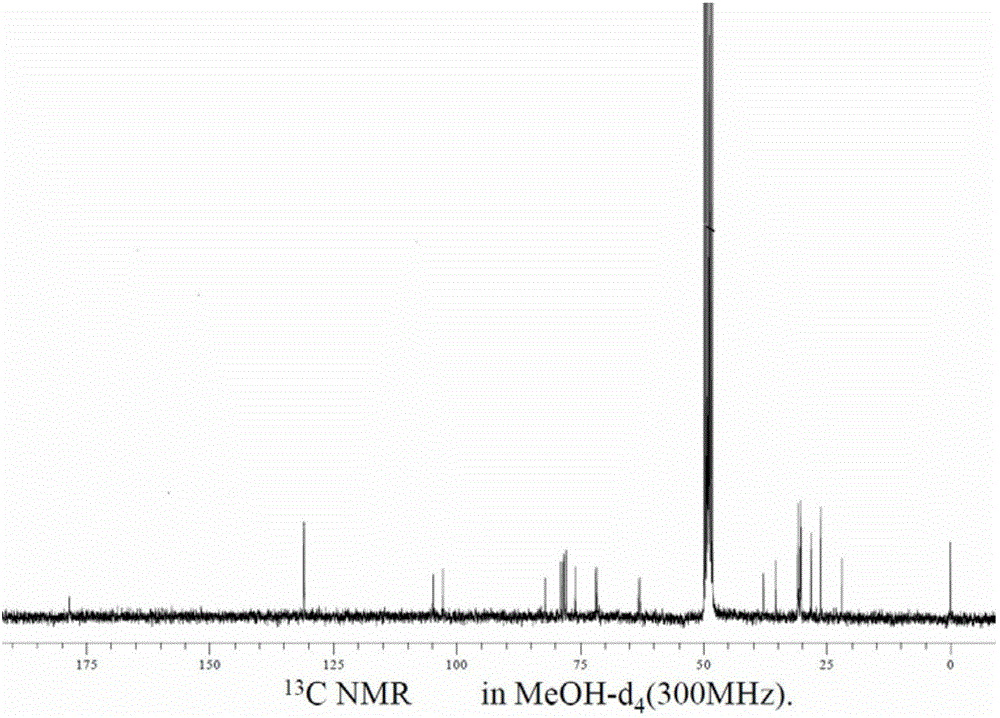

[0039] To a 100mL round-bottomed flask, 29.80g (43.27mmol, 1eq) of the fermentation product of Candida C.bombicola ATCC22214, 50mL of dry methanol and 1.62mL (6.49mmol, 0.15eq) of sodium methoxide, CaCl 2 Protect, heat to reflux for 3 hours, lower to room temperature, then add 25mL 20% KOH aqueous solution, continue to reflux for 2 hours, remove the solvent under reduced pressure, dissolve in deionized water, use HCl to adjust the pH until the phenol is red, and place in an ice bath until precipitation occurs , and the product was separated by silica gel column chromatography, and the mobile phase was chloroform / methanol (3:22to 4:22, v / v). 1 H NMR (CH 3 OH-d 4 ):5.35(2H,m,H-9and H-10),4.63(1H,d,J)8.1Hz,H-1"),4.44(1H,d,J)7.5Hz,H-1'), 3.82-3.87(3H,m,H-6'b,H-6"b,and H-17),3.63-3.68(3H,m,H-6'a,H-6"a,and H-5 "),3.53-3.58(2H,m,H-2'and H-3'),3.21-3.41(5H,m,H-3",H-2",H-4",H-4', and H-5'),2.27(2H,t,J)7.3Hz,H-2...

Embodiment 2

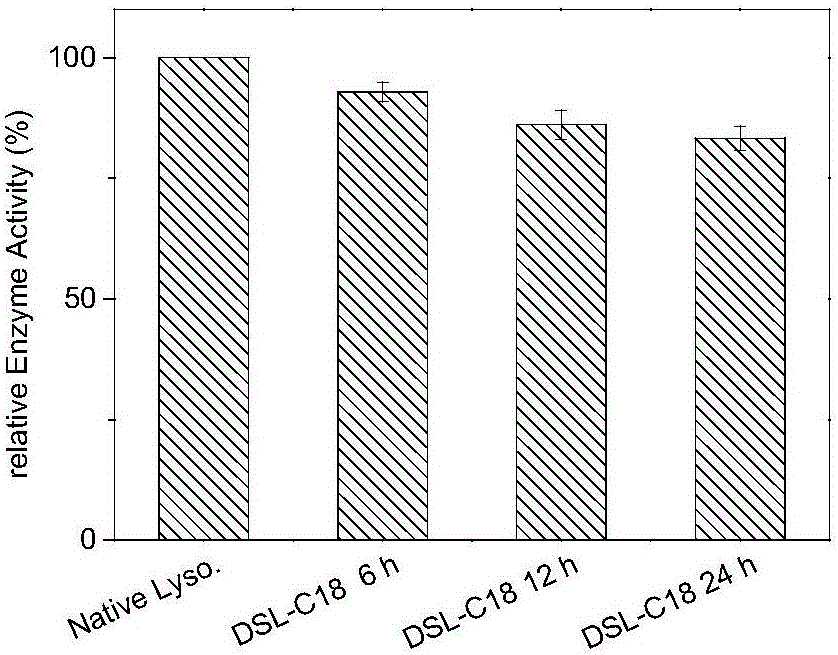

[0041] Covalent modification of native egg white lysozyme by carboxylic acid type acyl-free sophorolipid (DSL-C18):

[0042] 1) Dissolve the N-hydroxysuccinimide ester of the acyl sophorolipid derivative in 5mL DMSO to form a solution with a final concentration of 0.7mM, and add 25mL, 0.2mM, 1% NaHCO dropwise under stirring 3 Egg white lysozyme aqueous solution, continue to stir slowly and react at 30°C for 6h. After the reaction, add 25mL of 100mM glycine solution to the system, keep the temperature at 30°C for 10min, dialyze with deionized water at room temperature, then dialyze with 20mM phosphate buffer, pH 7.0, and maintain at 4°C for about 1 day. In order to remove unreacted acid-type peracetyl sophorolipids, the dialyzate was centrifuged at 12,000 rpm at 5°C for 10 min, and the suspension was collected as a seed.

[0043] 2) Determination of lysozyme activity:

[0044] Place the enzyme solution to be tested and the substrate suspension in a water bath at 25°C for 20 m...

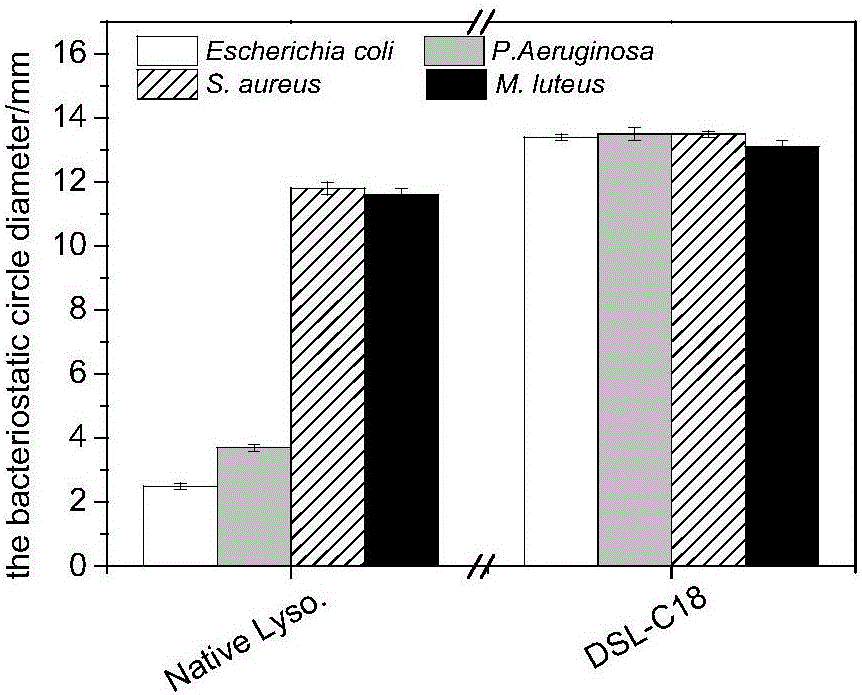

Embodiment 3

[0046] Determination of the inhibition zone: using the cup and saucer method. Take 20mL of melted solid culture-based culture dish, after solidification, take 0.2mL with a concentration of 10 6 -10 7 Each bacterial suspension of CFU / mL was evenly spread in the solid medium, and after 10 minutes, the Oxford cup was placed on the surface of the petri dish, the sample solution was added, the medium was covered, and cultured at a constant temperature of 37°C for 24 hours, and the inhibition zone was measured. diameter. Each sample solution experiment was repeated 3 times, and the average value was taken.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com