Power cable for water conservancy hydropower station

A technology for power cables and hydropower stations, applied in the field of water conservancy and hydropower, to achieve superior flame retardancy, soft texture, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

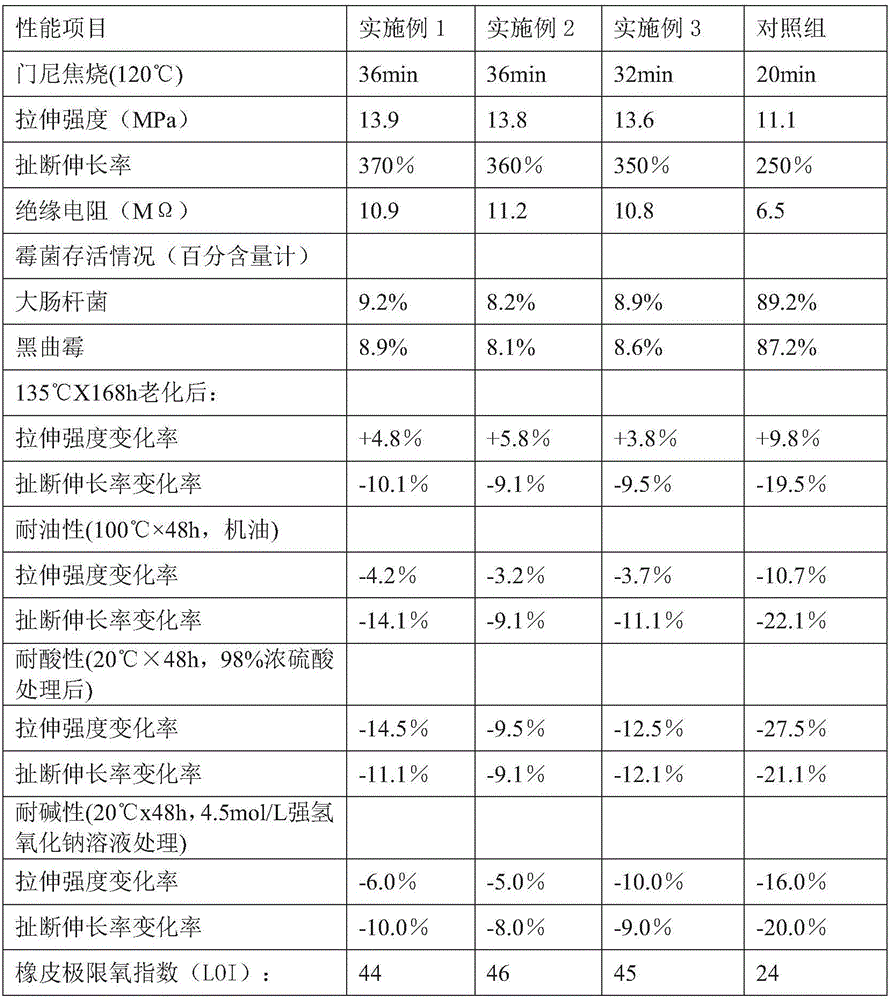

Embodiment 1

[0017] The power cable for water conservancy and hydropower stations in this embodiment includes multiple copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve consists of the following parts by mass: Component composition: 20 parts of furfuryl alcohol resin, 18 parts of hydrogenated rosin, 18 parts of bisphenol A polycarbonate, 16 parts of ethyl propionate, 18 parts of rapeseed oil, 18 parts of butyl acetate, 16 parts of soybean oil, 18 parts of bromodimethylhydantoin, 18 parts of dodecyl dimethyl benzyl ammonium chloride, 16 parts of 10,10'-oxobisphenoxarsenic, 16 parts of 8-hydroxyquinoline copper, eight 16 parts of methyl silicone oil, 18 parts of magnesium sulfate, 16 parts of ferric orthophosphate, 14 parts of ferrocene, 18 parts of high gloss barium, 16 parts of sucrose, 14 parts of lithium iodate powder, 16 parts of polyeste...

Embodiment 2

[0024] The power cable for water conservancy and hydropower stations in this embodiment includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve consists of the following parts by mass: Component composition: 22 parts of furfuryl alcohol resin, 20 parts of hydrogenated rosin, 20 parts of bisphenol A polycarbonate, 18 parts of ethyl propionate, 20 parts of rapeseed oil, 20 parts of butyl acetate, 18 parts of soybean oil, 20 parts of bromodimethylhydantoin, 20 parts of dodecyl dimethyl benzyl ammonium chloride, 18 parts of 10,10'-oxobisphenoxarpine, 18 parts of 8-hydroxyquinoline copper, eight 18 parts of methyl silicone oil, 20 parts of magnesium sulfate, 18 parts of ferric orthophosphate, 16 parts of ferrocene, 20 parts of high gloss barium, 18 parts of sucrose, 16 parts of lithium iodate powder, 18 parts of pol...

Embodiment 3

[0031] The power cable for water conservancy and hydropower stations in this embodiment includes multiple copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve consists of the following parts by mass: Component composition: 24 parts of furfuryl alcohol resin, 22 parts of hydrogenated rosin, 22 parts of bisphenol A polycarbonate, 20 parts of ethyl propionate, 22 parts of rapeseed oil, 22 parts of butyl acetate, 20 parts of soybean oil, 22 parts of bromodimethylhydantoin, 22 parts of dodecyl dimethyl benzyl ammonium chloride, 20 parts of 10,10'-oxobisphenoxarpine, 20 parts of 8-hydroxyquinoline copper, eight 20 parts of methyl silicone oil, 22 parts of magnesium sulfate, 20 parts of ferric orthophosphate, 18 parts of ferrocene, 22 parts of high gloss barium, 20 parts of sucrose, 18 parts of lithium iodate powder, 20 parts of polyester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com