Ultrafiltration Membrane Cleaning Method in Membrane Polymer Flooding Oil Production Wastewater Treatment

A technology for oil extraction wastewater and ultrafiltration membrane, applied in the field of membrane cleaning, can solve the problems of poor pertinence, general polymer pollution cleaning effect, limited cleaning steps and cleaning methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

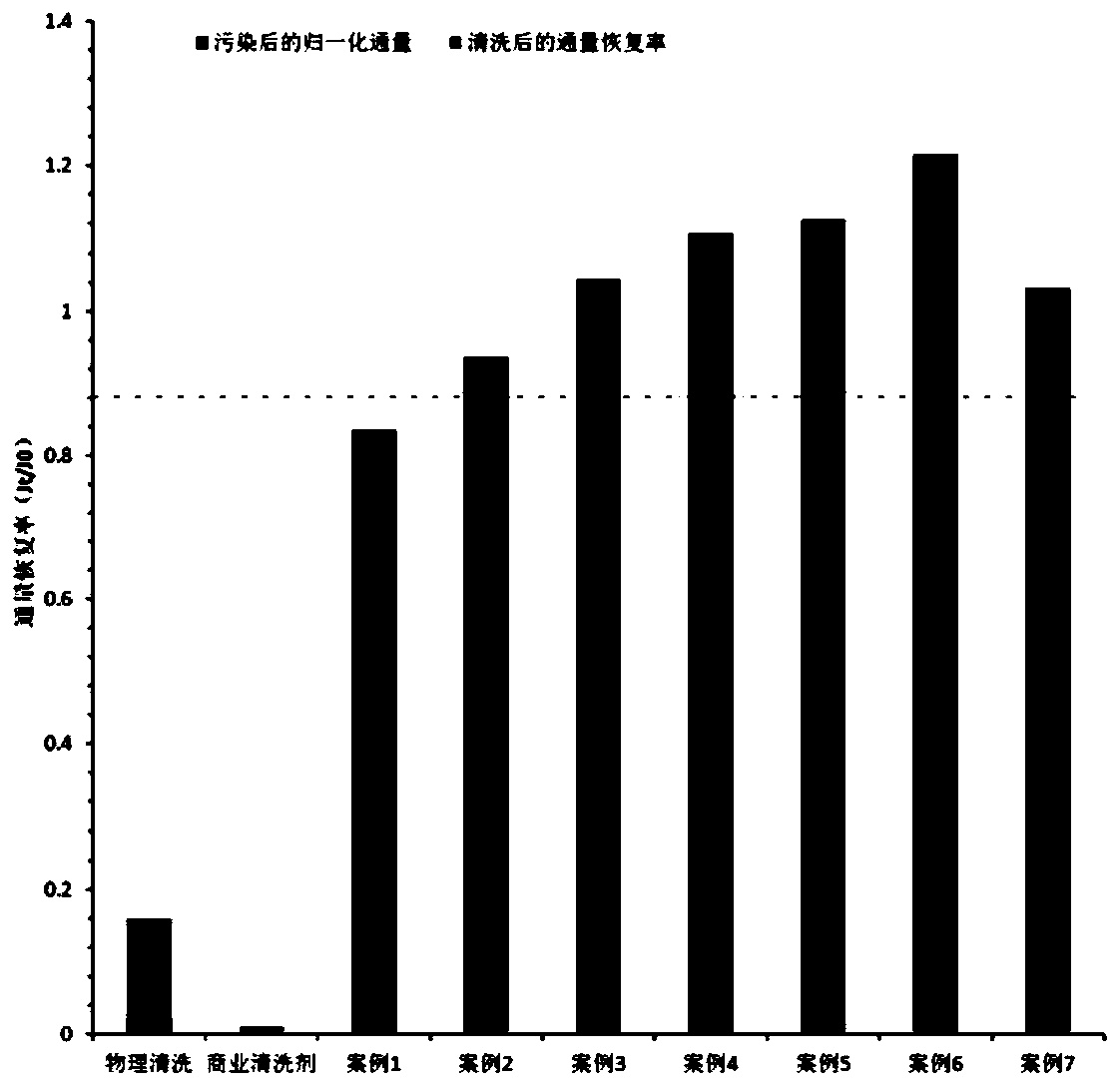

Examples

Embodiment 1

[0065] Process conditions:

[0066] Contaminated membrane: Ultrafiltration treatment of ultrafiltration polluted membrane in polymer flooding wastewater in Daqing Oilfield;

[0067] Cleaning temperature: 40°C;

[0068] Cleaning method: static soaking;

[0069] Cleaning time: each step is different;

[0070] Preparation of cleaning solution: use water as solvent;

[0071] (i) Hydrochloric acid lotion of sodium hydrogen fluoride: the molar concentration of sodium hydrogen fluoride is 0.05 moles per liter; Regulate pH=2.0 with hydrochloric acid; Cleaning time is 180 minutes;

[0072] (ii) Oxidant lotion: sodium hypochlorite volume concentration is 0.2%; Regulate pH=10 with sodium hydroxide; Cleaning time is 60 minutes;

[0073] (iii) Surfactant lotion: the molar concentration of anionic surfactant (sodium dodecylbenzenesulfonate) is 4.0CMC (critical micelle concentration), nonionic surfactant (OP-10, purchased from Sinopharm Group) concentration is 2.0CMC; Regulate pH=12 wit...

Embodiment 2

[0080] Process conditions:

[0081] Contaminated membrane: Ultrafiltration treatment of ultrafiltration polluted membrane in polymer flooding wastewater in Daqing Oilfield;

[0082] Cleaning temperature: room temperature;

[0083] Cleaning method: 0.3MPa cycle pressure cleaning;

[0084] Cleaning time: each step is different;

[0085] Preparation of cleaning solution: use water as solvent;

[0086] (i) Hydrochloric acid lotion of sodium hydrogen fluoride: the molar concentration of sodium hydrogen fluoride is 0.05 moles per liter; Regulate pH=2.0 with hydrochloric acid; Cleaning time is 180 minutes;

[0087] (ii) mixed lotion of oxidizing agent and tensio-active agent: sodium hypochlorite volume concentration is 0.2%; Anionic surfactant (sodium dodecylbenzene sulfonate) concentration is 0.2CMC; Regulate pH=12 with sodium hydroxide; Cleaning time is 120 minutes;

[0088](iii) Sodium bifluoride and nitric acid, hydrochloric acid washing solution: the molar concentration of ...

Embodiment 3

[0094] Process conditions:

[0095] Contaminated membrane: ultrafiltration membrane polluted by pure polyacrylamide;

[0096] Cleaning temperature: room temperature;

[0097] Cleaning method: static soaking;

[0098] Cleaning time: 120 minutes;

[0099] Preparation of cleaning solution: use water as solvent;

[0100] (i) Alkali lotion of oxidant and disodium edetate: the volume concentration of sodium hypochlorite is 0.15%; the molar concentration of disodium edetate is 5.0mM; adjust pH=11.0 with sodium hydroxide;

[0101] (ii) Alkali lotion of oxidizing agent and tensio-active agent: the volume concentration of sodium hypochlorite is 0.05%; The molar concentration of cationic surfactant (dodecyltrimethylammonium chloride) is 4.0CMC; Regulate pH with sodium hydroxide = 11.0;

[0102] (iii) Hydrochloric acid washing solution: hydrochloric acid, pH=4.0.

[0103] Cleaning steps:

[0104] Physical cleaning first: wash the polluted membrane surface with clean water and backw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com