Carbon fiber oil-resisting modified nano green and environment-friendly construction base material and preparation method thereof

A technology of green environmental protection and building base material, applied in the field of building decoration materials, can solve the problems affecting the use of rubber powder polystyrene particle thermal insulation mortar, poor wall adhesion, slow drying speed, etc., so as to improve the thermal aging cracking resistance. , The effect of fast curing speed and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

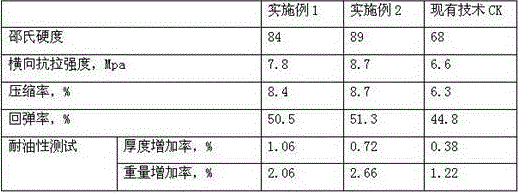

Embodiment 1

[0014] Embodiment 1 A carbon fiber oil-resistant modified nano-green environmental protection building substrate and its preparation method

[0015] A carbon fiber oil-resistant modified nano-green environmental protection building substrate, which includes the following raw materials: 50 parts of nitrile rubber, 30 parts of polyurethane rubber, 10 parts of 12-hydroxy methyl stearate, 8 parts of magnesium methacrylate, ethylene 6 parts of methyl tributyl ketoxime silane, 20 parts of nylon 66 short fiber, 5 parts of polytrimethylene adipate, 10 parts of diethylene glycol dibenzoate, 30 parts of pitch-based carbon fiber powder, non-halogenated organic phosphinic acid 5 parts of ester, 8 parts of hexamethylenetetramine, 2 parts of trimethylpentyltriethoxysilane, 10 parts by weight of rubber powder slurry, 6 parts by weight of polystyrene particles, 12 parts by weight of methyl cellulose, 5 parts by weight of toner, 4 parts by weight of polypropylene fiber, 1 part by weight of sta...

Embodiment 2

[0022] Embodiment 2 A carbon fiber oil-resistant modified nano-green environmental protection building substrate and its preparation method

[0023] A carbon fiber oil-resistant modified nano-green environmental protection building substrate, which includes the following raw materials: 60 parts of nitrile rubber, 40 parts of polyurethane rubber, 15 parts of 12-hydroxy methyl stearate, 12 parts of magnesium methacrylate, ethylene 10 parts of tributyl ketoxime silane, 25 parts of nylon 66 staple fiber, 10 parts of polypropylene adipate, 16 parts of diethylene glycol dibenzoate, 35 parts of pitch-based carbon fiber powder, non-halogenated organic phosphinic acid 7 parts of ester, 10 parts of hexamethylenetetramine, 4 parts of trimethylpentyltriethoxysilane, 20 parts by weight of rubber powder slurry, 10 parts by weight of polystyrene particles, 18 parts by weight of methylcellulose, 15 parts by weight of toner, 10 parts by weight of polypropylene fiber, 5 parts by weight of starc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com