Method for preparing high-carbon hydrocarbons from methane through vacuum ultraviolet radiation

A vacuum ultraviolet and ultraviolet radiation technology, applied in the chemical industry, can solve the problems of inability to transmit quartz glass, large light energy loss, etc., and achieve the effect of prolonging the residence and radiation time and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

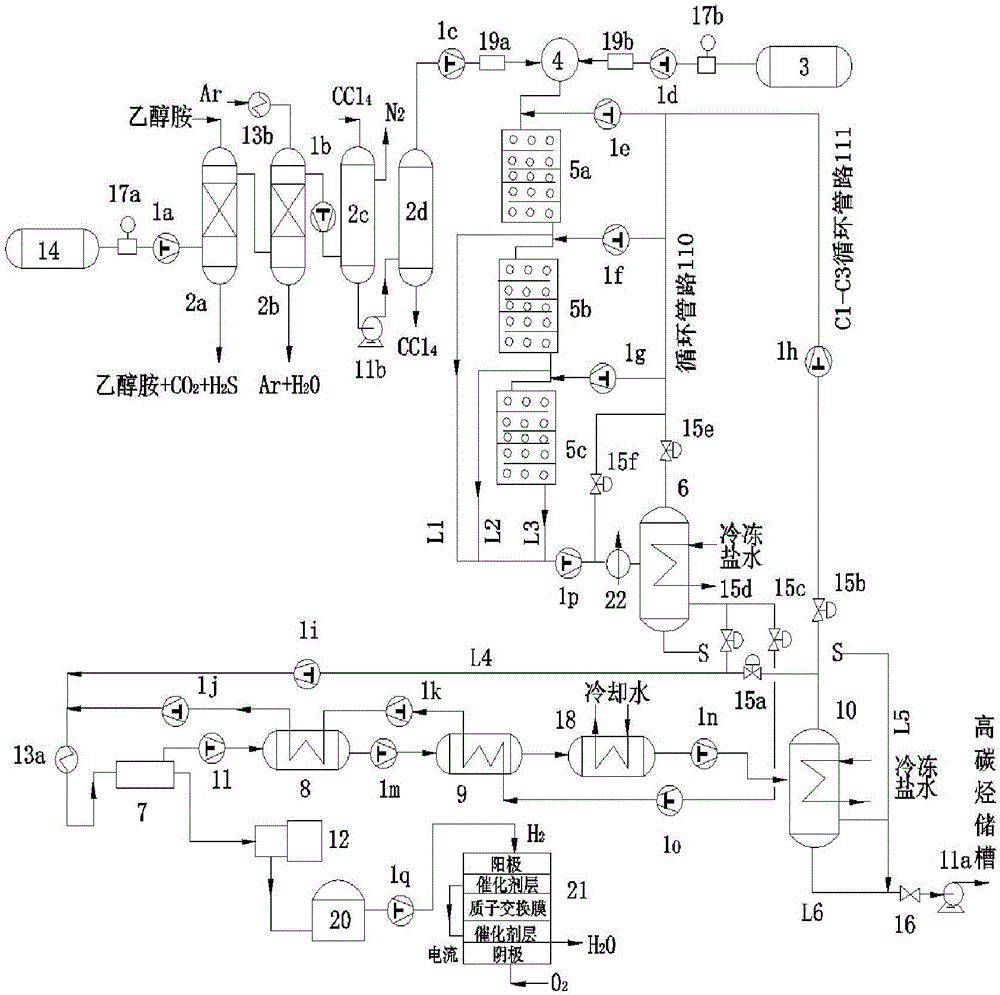

[0035] First, the natural gas (containing more than 90% methane) or biomethane (containing 50-80% methane, 20-45% carbon dioxide and nitrogen) from the storage tank is passed through the pressure reducing valve 17a, and the gas pump 1a is used to pump H from the lower part of the tower countercurrently. 2 S and CO 2 The absorption tower 2a flows out from the top of the tower, and ethanolamine is ejected from the top of the absorption tower 2a, and after the countercurrent contact of the packing layer with methane, it flows out from the bottom of the tower, and the ethanolamine is used to treat H 2 S and CO 2 Has greater solubility, while methane is insoluble in ethanolamine, will dissolve H 2 S and CO 2 The ethanolamine of the impurity gas is brought out; the methane gas overflowing from the upper part of 2a enters the molecular sieve water absorption tower 2b from the lower part (one is opened and the other is prepared), and the moisture is transferred from the methane gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com