Preparation method of GO (graphene oxide)-SiO2 hybrid particle composite fiber super/microfiltration membrane

A technology of hybrid particles and composite fibers, which is applied in chemical instruments and methods, ultrafiltration, membranes, etc., can solve the problems of poor compatibility between inorganic materials and organic phase solvents, and easy agglomeration of composite membrane nanomaterials, so as to reduce the inherent span Effects of Membrane Resistance, Enhanced Hydrophilicity, and Increased Solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

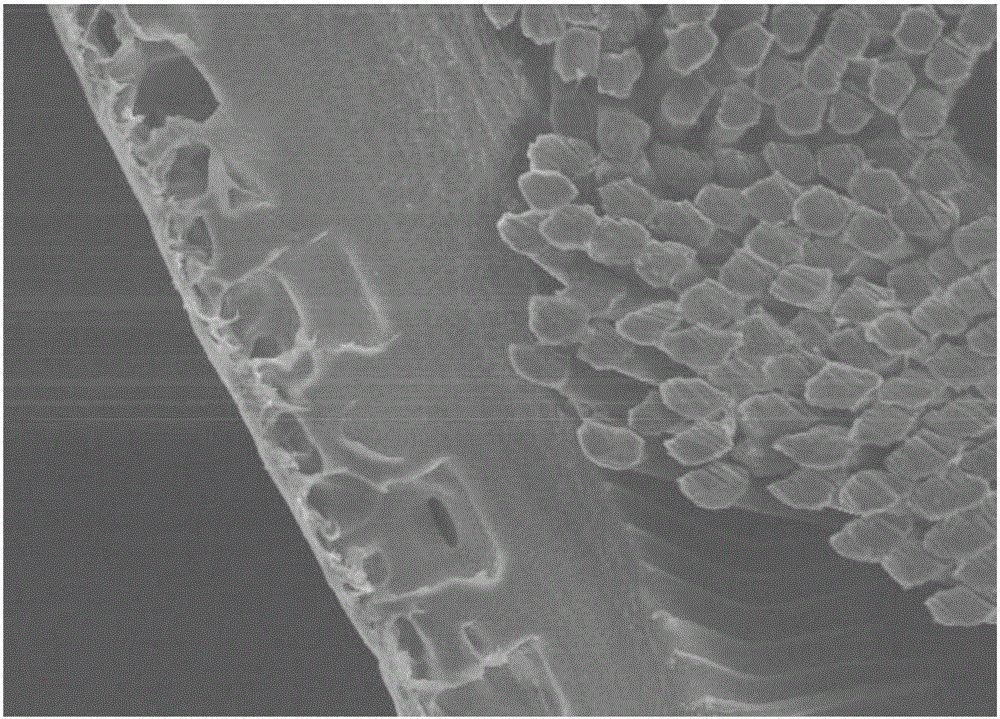

[0031] A preparation method of graphene oxide-silicon dioxide hybrid particle composite fiber ultra / microfiltration membrane, comprising the following steps:

[0032] 1) Preparation of graphene oxide-silica hybrid particles: prepare a mixed solution with a concentration of 60-95 wt% absolute ethanol and pure water, add 2-50 mg of graphene oxide powder to 1L of the mixed solution according to the mass ratio, Adjust the pH value to 8.0-9.0 to obtain an alkaline solution, drop 0.5-5mL tetraethyl orthosilicate into 1L of alkaline solution according to the mass ratio, ultrasonicate, store at room temperature for 20-30h, centrifuge, and wash repeatedly with absolute ethanol The filter cake was vacuum freeze-dried for 24 hours, and the obtained particles were stored for future use;

[0033] 2) Preparation of coating casting solution: Graphene oxide-silicon dioxide hybrid particles with a mass fraction of 0.1 to 1% are added to 60 to 91% of organic solvents (N-N dimethylacetamide, N-N...

Embodiment 1

[0043] 1) Preparation of graphene oxide-silica hybrid particles: prepare a mixed solution with a concentration of 60wt% absolute ethanol and pure water, add 2mg graphene oxide powder to the mixed solution with a mass ratio of 1L, and adjust the pH value to 8.0, add 0.5mL tetraethyl orthosilicate dropwise to 1L alkaline mixed solution for sonication, sonicate the resulting solution for 0.5h, store at room temperature for 20h. Afterwards, the mixed solution was centrifuged, and the filter cake was repeatedly washed with absolute ethanol for 3 times, vacuum freeze-dried for 24 hours, vacuum freeze-dried, and the obtained particles were stored for future use;

[0044] 2) Preparation of coating casting solution: add 0.1% graphene oxide-silica hybrid particles to 90.89% organic solvent (N-N dimethylacetamide, N-N dimethylformamide, tetrahydrofuran 1 :1:1 blending), high-speed stirring for 10 minutes, mechanical stirring speed of 50rpm. Add 0.001wt% solubilizer (0.015:1 mixture of t...

Embodiment 2

[0054] 1) Preparation of graphene oxide-silica hybrid particles: prepare a mixed solution with a concentration of 70wt% absolute ethanol and pure water, add 5 mg of graphene oxide powder to the mixed solution with a mass ratio of 1L, and adjust the pH value to 8.3. Add 1.0mL tetraethyl orthosilicate dropwise to 1L alkaline mixed solution for sonication, sonicate the resulting solution for 1h, and store it at room temperature for 20h. Afterwards, the mixed solution was centrifuged, and the filter cake was repeatedly washed with absolute ethanol for 4 times, vacuum freeze-dried for 24 hours, and vacuum freeze-dried, and the obtained particles were stored for future use;

[0055] 2) Preparation of coating casting solution: add 0.3% graphene oxide-silica hybrid particles into 88.69% organic solvent (dichloromethane, formic acid, acetone 1:1:1 blend) , high-speed stirring for 15min, mechanical stirring speed of 50rpm. Add 0.002wt% solubilizer (0.02:1 mixture of triethanolamine TEO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water flux | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Pure water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com