Production technology of high-density composite nitrobacterium inoculant, and high-density fermentation batch culture fermentation tank system of nitrobacteria

A technology of nitrifying bacteria and production process, applied in the field of environmental biology, can solve the problems of lack of production process, hinder the productization and commercialization process of nitrifying bacteria, etc., to increase the biomass of nitrifying bacteria, reduce the sedimentation separation tank and flocculation stirring tank, The effect of increasing cell density and resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

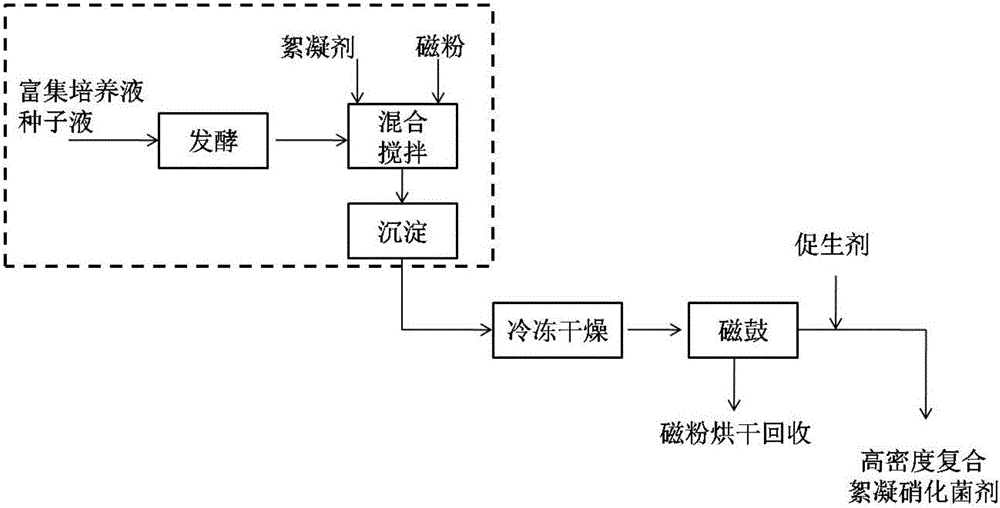

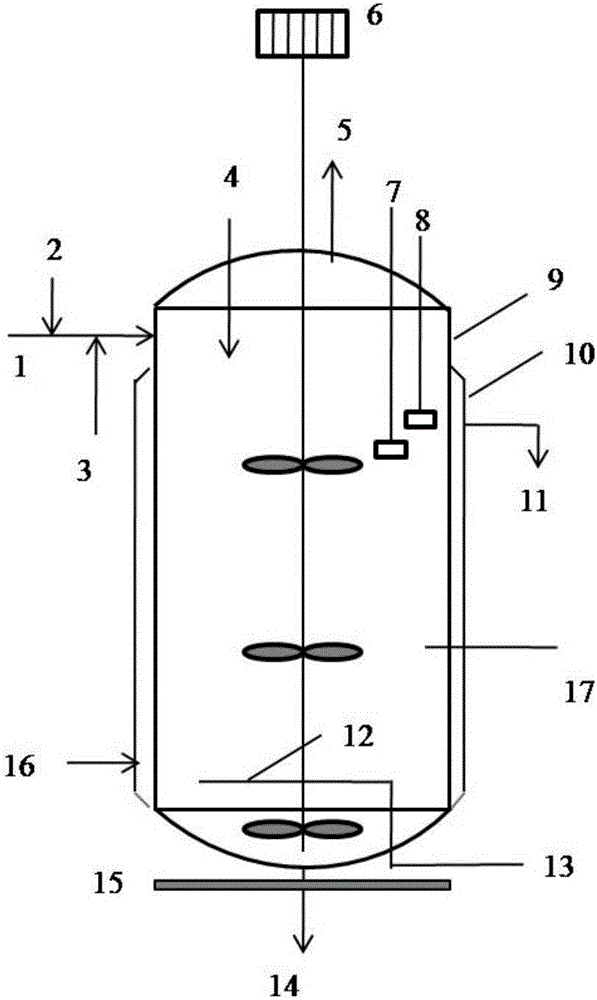

Method used

Image

Examples

Embodiment 1

[0043] 1) Seed culture of nitrifying bacteria: take nitrifying sludge from urban sewage treatment plant and inoculate it in a 1L Erlenmeyer flask with an inoculum size of 10%. The Erlenmeyer flask is filled with 300mL medium, and each liter of medium contains: NaHCO3 1.5g, CH 3 COONa 0.5g, (NH4) 2 SO 4 5.0g, NaCl 1.0g, FeSO4 0.2g, K 2 HPO 4 1.0g, MgSO 4 0.25g, used as seed liquid after culturing for 5 days;

[0044] 2) Preparation by co-precipitation method: take 43.2g FeCl 3 ·6H 2 O and 24.70 g FeCl 2 4H 2 O was added to a three-necked flask, and mixed with an appropriate amount of sodium citrate (final concentration: 0.02mol / L) as a dispersant, and placed on a constant temperature heating magnetic stirrer. Under the protection of nitrogen, heat up to 60°C, 1000r / min, stir at constant temperature for 8-10min, then add 2mol / L NaOH solution dropwise until the pH of the solution is 11, continue to react for 60min, and cool down to room temperature naturally. Wash thr...

Embodiment 2

[0053] 1) Seed culture of nitrifying bacteria: Take nitrifying sludge from urban sewage treatment plant and inoculate it in a 1L conical flask with an inoculum size of 10%. The conical flask is filled with 300mL medium, and each liter of medium contains: NaHCO 3 1.5g, CH 3 COONa 0.5g, (NH 4 ) 2 SO 4 5.0g, NaCl 1.0g, FeSO 4 0.2g,K 2 HPO 4 1.0g, MgSO4 0.25g, used as seed liquid after culturing for 5 days;

[0054] 2) Preparation by co-precipitation method: take 43.2g FeCl 3 ·6H 2 O and 24.70 g FeCl 2 4H 2 O was added to a three-necked flask, and mixed with an appropriate amount of sodium citrate (final concentration: 0.02mol / L) as a dispersant, and placed on a constant temperature heating magnetic stirrer. Under the protection of nitrogen, heat up to 60°C, 1000r / min, stir at constant temperature for 8-10min, then add 2mol / L NaOH solution dropwise until the pH of the solution is 11, continue to react for 60min, and cool down to room temperature naturally. Wash thre...

Embodiment 3

[0061] Embodiment 3 composite nitrifying bacteria bacterial agent is to the ammonia nitrogen degradation of urban water body

[0062] 1) Refer to steps 1-6 of Example 2 to obtain a composite nitrifying bacteria bacterial agent.

[0063] 2) Take the surface water from Donghu Lake in Maanshan City. The main water quality parameters COD, BOD, ammonia nitrogen, total nitrogen, and total phosphorus concentration are 74-139mg / L, 34.8-41mg / L, 6.47-12.16mg / L, 9.50-13.2mg / L, respectively. L, 0.35~0.86mg / L. Add dry powder of compound nitrifying bacteria agent to 2000-5000mL test water at a concentration of 2-4mg / L, aerate and oxygenate to ensure that the dissolved oxygen concentration in the water is not less than 2mg / L, and after 5-7 days, the ammonia nitrogen in the water will degrade The rate reaches 91.2-98.7%, and the turbidity of the water body drops from the original 22.6-23.9 NTU to 8.4-8.6 NTU (NTU is equivalent to 1 mg of SiO in 1 L of water. 2 Or when it is unbent kaolin or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com