Precursor polymer microsphere and preparation method thereof

A precursor and polymer technology, which is applied in the field of precursor polymer microspheres and its preparation, can solve the problems of difficult control of coating quality, inability to produce boron carbide ceramic microspheres with high efficiency and high quality, and achieve boron source saving, Mild conditions, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

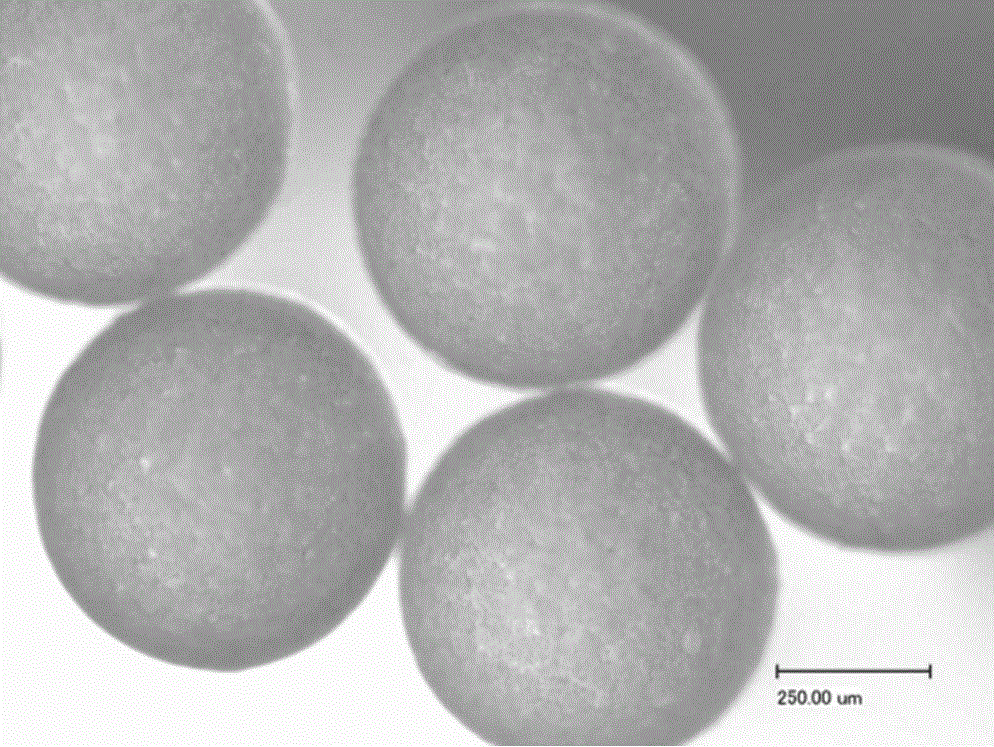

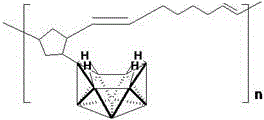

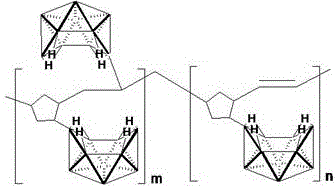

[0030] a. Dissolving poly(6-norbornenyldecaborane-co-decaborane) in fluorobenzene, the weight average molecular weight of the precursor polymer ( M w ) is 68000, and the mass percentage of the solution is 30%. Configuration mass percentage is the polyvinyl alcohol aqueous solution of 2% as external phase;

[0031] b. Use three microsyringe pumps to press deionized water, polycarborane precursor solution and polyvinyl alcohol aqueous solution into the innermost phase, intermediate phase and outer phase of the microchannel template respectively, so that the three phases form water / oil / water ( W1 / O / W2) double emulsion system;

[0032] c. Collect the emulsion in a rotary bottle equipped with an external water phase, and place it in an emulsion rotary curing device, and the curing temperature is 30 o C, rotate clockwise around the horizontal axis at 25 rpm, and cure for 24 h;

[0033] d. Pour the liquid in the spinner bottle into a sieve to remove the outer water phase, wash it...

Embodiment 2

[0035] a. Dissolving poly(6-norbornenyldecaborane-co-1,5 hexadiene) in benzene, the weight average molecular weight of the precursor polymer ( M w ) is 5200, and the mass percentage of the solution is 20%. Configuration mass percentage is the polyvinyl alcohol aqueous solution of 2% as external phase;

[0036] b. Use three microsyringe pumps to press deionized water, polycarborane precursor solution and polyvinyl alcohol aqueous solution into the innermost phase, intermediate phase and outer phase of the microchannel template respectively, so that the three phases form water / oil / water ( W1 / O / W2) double emulsion system;

[0037] c. Collect the emulsion in a rotary bottle equipped with an external water phase, and place it in an emulsion rotary curing device, and the curing temperature is 20 o C, rotate clockwise around the horizontal axis at 25 rpm, and cure for 48 h;

[0038] d. Pour the liquid in the spinner bottle into a sieve to remove the outer water phase, wash it sev...

Embodiment 3

[0040] a. Poly(6-norbornenyldecaborane-co-norbornene), benzene and 1,2-dichloroethane are configured in the oil phase at a mass fraction of 10: 45: 45, and the weight of the precursor polymer is average molecular weight ( M w ) is 15000, and the mass percentage of the solution is 10%. And configuration mass percentage is the polyvinyl alcohol aqueous solution of 4% as external phase;

[0041] b. Use three microsyringe pumps to press deionized water, polycarborane precursor solution and polyvinyl alcohol aqueous solution into the innermost phase, intermediate phase and outer phase of the microchannel template respectively, so that the three phases form water / oil / water ( W1 / O / W2) double emulsion system;

[0042] c. Collect the emulsion in a rotary bottle equipped with an external water phase, and place it in an emulsion rotary curing device, and the curing temperature is 10 o C, rotate clockwise around the horizontal axis at 25 rpm, and cure for 72 h;

[0043]d. Pour the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com