Low-temperature petroleum coke negative electrode material coated with nitrogenous polymer pyrolytic carbon on surface and preparation method of low-temperature petroleum coke negative electrode material

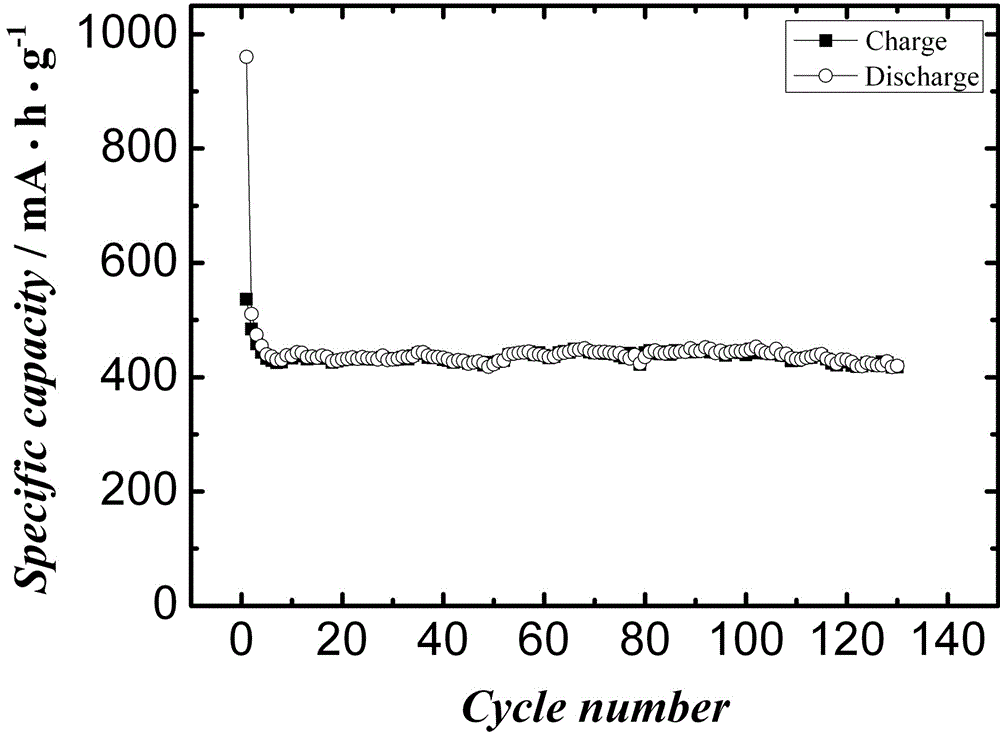

A surface coating and negative electrode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the complex impurity content or purity difference of industrial-grade petroleum coke element components, and the particle aggregation state and distribution difference in the chemical state of the microcrystalline surface. It is very large, restricting the industrial application of petroleum coke materials, etc., to achieve good cycle performance, environmental friendliness, and improved cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

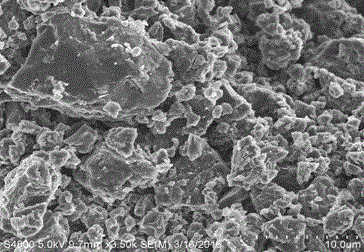

[0041] (1) Grind industrial petroleum coke to a particle size of 0.1-1 mm, put it in a high-speed pulverizer for further crushing, pass through a 600-mesh sieve, and take the lower part of the fine powder as a raw material for use. The low-temperature petroleum coke raw materials for the experiment are the above-mentioned Fine powder, denoted as Y1;

[0042] (2) Weigh 0.5 g of polyacrylonitrile and dissolve it in 50 mL of N,N-dimethylformamide solution, add 10 g of low-temperature petroleum coke raw material (Y1) after complete dissolution, and perform vacuum rotary evaporation after magnetic stirring for 2 h , the obtained rotary evaporated solid was dried in an oven at 60 °C for 2 h, and then placed in a muffle furnace for pre-oxidation treatment at 240 °C for 2 h, and then the pre-oxidized sample was placed in a N 2 The tube furnace was sintered at 300 °C for 2 h, then raised to 700 °C for 9 h, and the sintered sample was taken out for grinding and 800-mesh sieving to obtai...

Embodiment 2

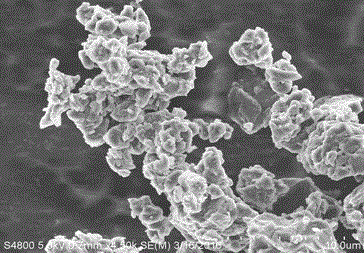

[0048] (1) First weigh 0.6 g of ammonium persulfate and dissolve it in 20 mL of deionized water, and place it in a separatory funnel for later use;

[0049] (2) Add 0.2 g of aniline liquid dropwise to 50 mL of 1.2 mol L -1 Stir in the HCl solution, then add 8 g of low-temperature petroleum coke raw materials and mix evenly. After stirring for 2 h, transfer to a 250 mL three-necked flask and reflux in an 80°C oil bath for 2 h. After cooling to room temperature, transfer to an ice-water bath. Ammonium persulfate solution was added dropwise to the mixture at a speed of 100°C, and finally the mixture was suction-filtered, washed with deionized water several times until the pH was 7, and the obtained filter residue was dried in an oven at 60 °C for 2 h and then placed in a N 2 The tube furnace was sintered at 300°C for 2 hours, then raised to 700°C for 9 hours, and the sintered samples were taken out for grinding and 800-mesh sieving to obtain a low-temperature petroleum coke negat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com