Kitchen waste recycling produced microorganism fertilizer with nitrogen fixation and phosphate and potassium dissolving effects

A technology for microbial fertilizer and kitchen waste, applied in the field of microbial fertilizer and waste recycling, can solve the problems of high production cost and complicated preparation process, increase soil organic matter and total nitrogen content, avoid antagonism, and promote synergistic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

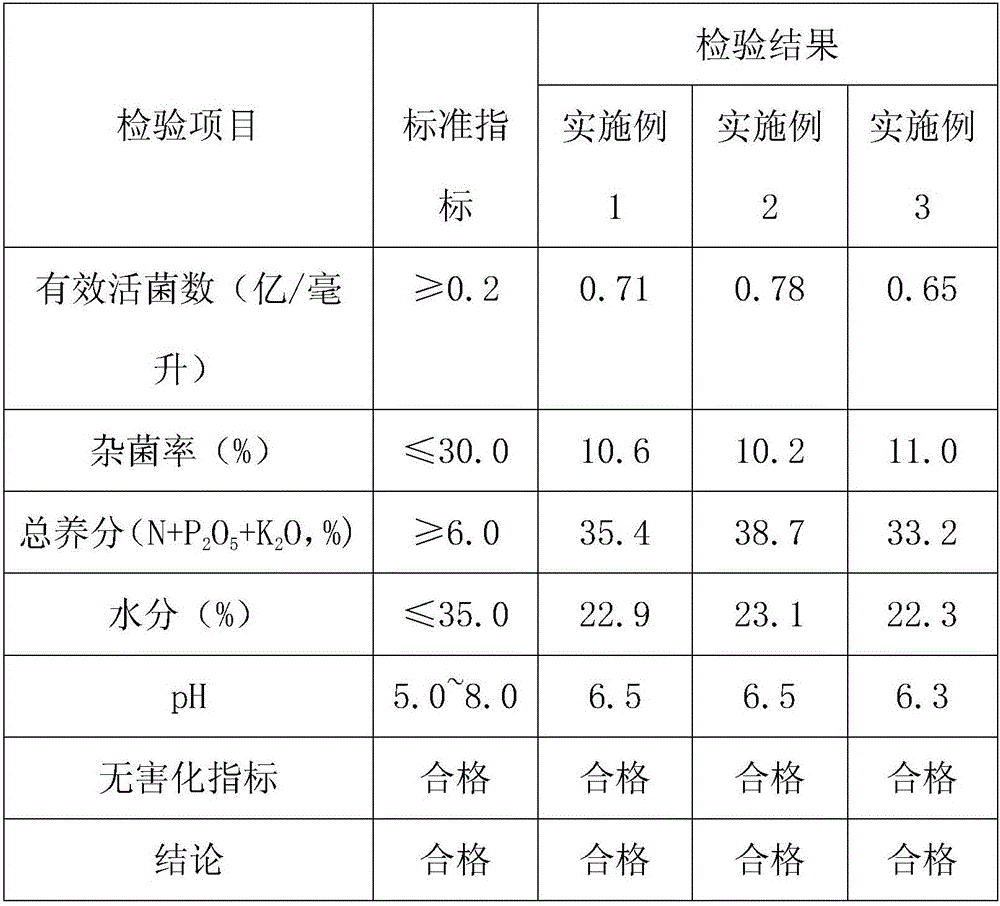

Embodiment 1

[0035] The microbial fertilizer with nitrogen-fixing, phosphorus-, and potassium-decomposing effects produced by resource utilization of food waste comprises 85% of compound microbial bacterial agent and 15% of sodium lauryl sulfate in parts by weight.

[0036] The preparation method of the above-mentioned food waste recycling to produce microbial fertilizers with nitrogen-fixing, phosphorus-, and potassium-decomposing effects includes the following steps:

[0037] (1) Preparation of trace element nutrient solution: Weigh 1% of zinc sulfate, 2% of ferrous sulfate, 1.5% of borax, 2% of copper sulfate, 0.8% of manganese sulfate, and 0.2% of sodium molybdate by weight percentage, and add the balance Stir in deionized water until the solids are completely dissolved (according to the content of soil trace elements in different regions and the requirements of the crops to be planted, corresponding trace elements can be added);

[0038] (2) Food waste pretreatment: Weigh 90% of food ...

Embodiment 2

[0044] The microbial fertilizer with nitrogen-fixing, phosphorus-, and potassium-decomposing effects produced by resource utilization of food wastes comprises, by weight, 90% of compound microbial bacterial agent and 10% of sodium lauryl sulfate.

[0045] The preparation method of the above-mentioned food waste recycling to produce microbial fertilizers with nitrogen-fixing, phosphorus-, and potassium-decomposing effects includes the following steps:

[0046] (1) Preparation of trace element nutrient solution: Weigh 1% of zinc sulfate, 2% of ferrous sulfate, 1.5% of borax, 2% of copper sulfate, 0.8% of manganese sulfate, and 0.2% of sodium molybdate by weight percentage, and add the balance Stir in deionized water until the solids are completely dissolved (according to the content of soil trace elements in different regions and the requirements of the crops to be planted, corresponding trace elements can be added);

[0047] (2) Food waste pretreatment: Weigh 85% of food waste ...

Embodiment 3

[0053] The microbial fertilizer with nitrogen-fixing, phosphorus-, and potassium-decomposing effects produced by resource utilization of kitchen wastes comprises, by weight, 95% of compound microbial bacterial agent and 5% of sodium lauryl sulfate.

[0054] The preparation method of the above-mentioned food waste recycling to produce microbial fertilizers with nitrogen-fixing, phosphorus-, and potassium-decomposing effects includes the following steps:

[0055] (1) Preparation of trace element nutrient solution: Weigh 1% of zinc sulfate, 2% of ferrous sulfate, 1.5% of borax, 2% of copper sulfate, 0.8% of manganese sulfate, and 0.2% of sodium molybdate by weight percentage, and add the balance Stir in deionized water until the solids are completely dissolved (according to the content of soil trace elements in different regions and the requirements of the crops to be planted, corresponding trace elements can be added);

[0056] (2) Food waste pretreatment: Weigh 82% of food wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com