Method for preparing super-hydrophobic mixed matrix membrane by inorganic particle induced phase separation

A technology of mixed matrix membrane and inorganic particles, which is applied in the field of membrane separation, can solve the problems of increased water vapor permeation resistance, unsatisfactory performance, and unfavorable environmental protection, and achieve stable membrane microstructure and hydrophobic characteristics, and the preparation method is simple and easy. , The effect of superhydrophobic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Mix 110.6g of dimethylacetamide, 30g of polyvinylidene fluoride, 38.5g of propylene glycol, 6.5g of butanol, and 2.7g of silicon dioxide with a particle size of 0.25μm, and cast the film on a glass plate at a temperature of 80°C. Scratch film.

[0042] The resulting membrane has a contact angle of 153° and a water flux of 27.8 L / m 2 .h, porosity 76%.

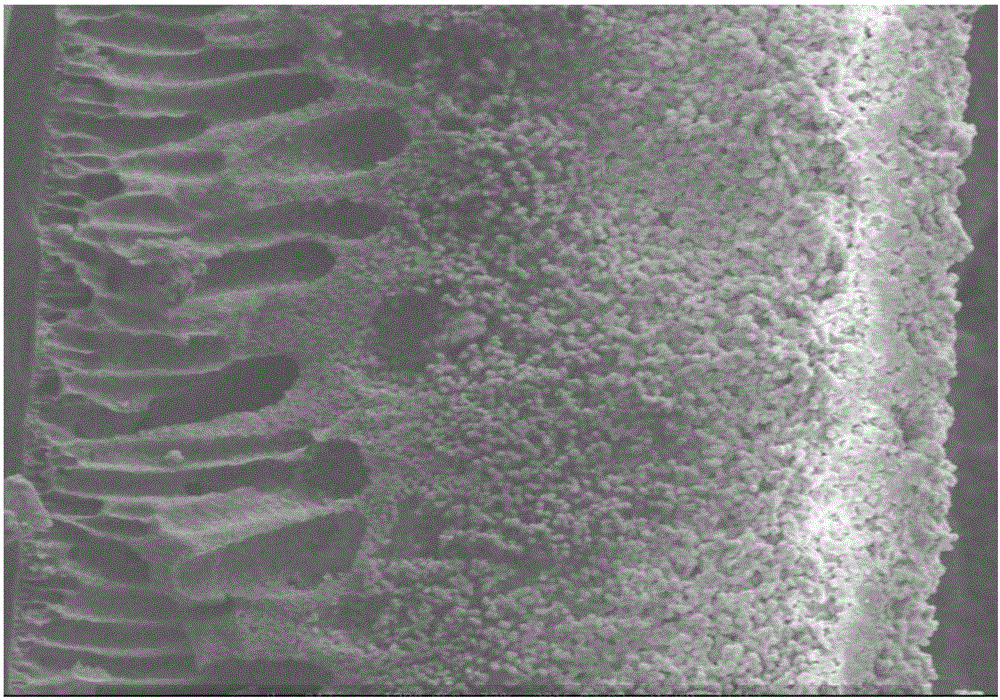

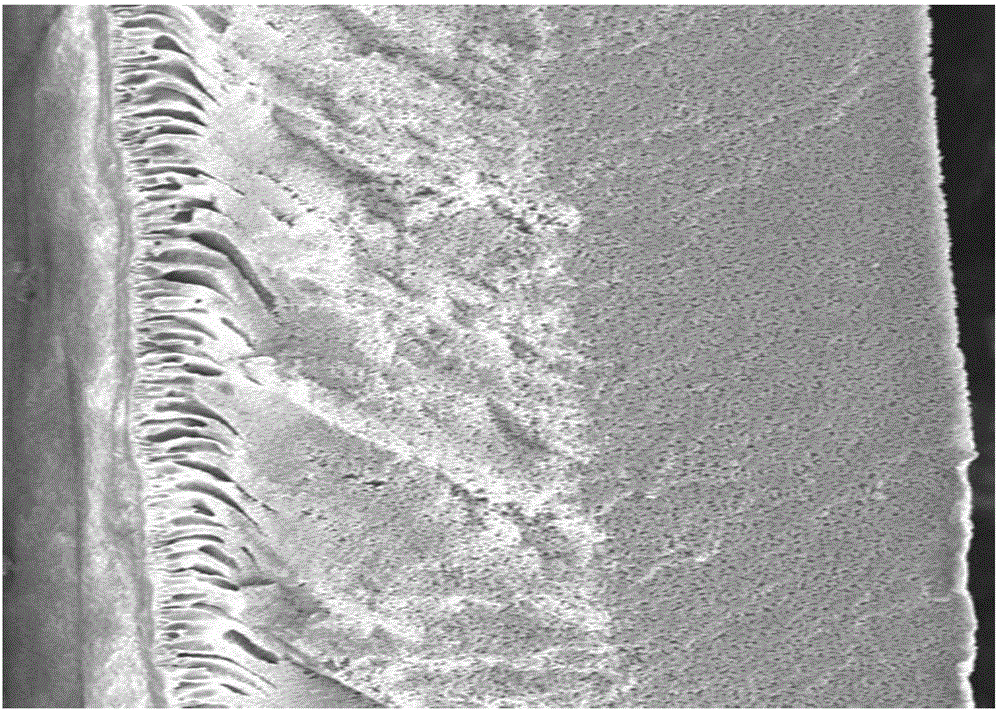

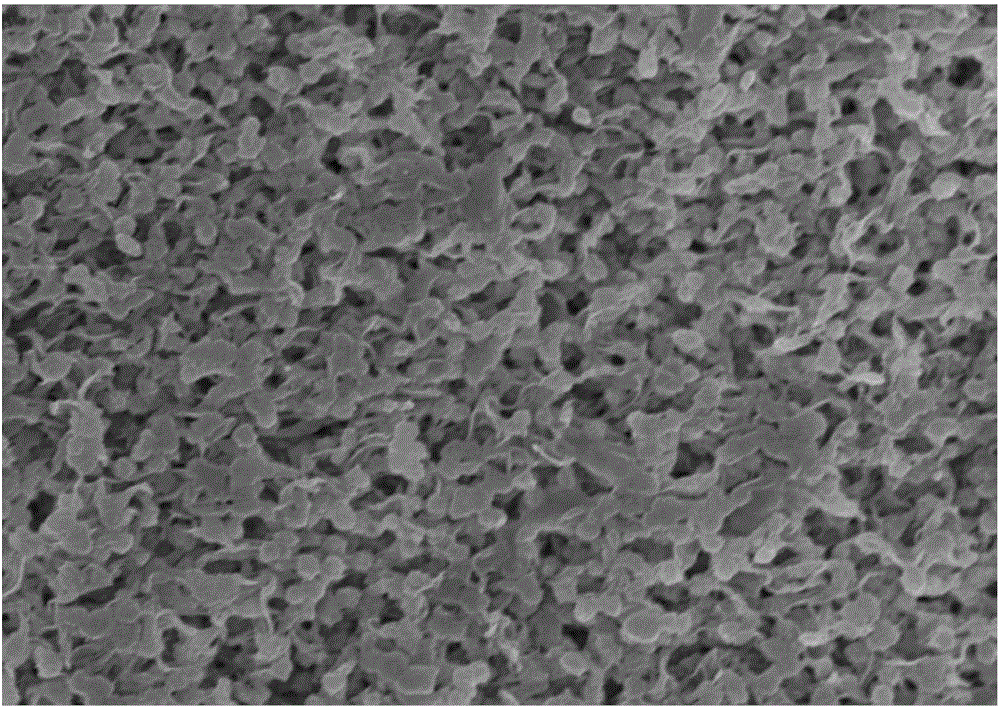

[0043] When alcohol is used as a non-solvent additive, it can inhibit the mass transfer rate of the solvent and non-solvent during the film formation process, which is beneficial to the crystallization of the polymer, and the inorganic particles can play a nucleating role, thereby inducing the crystallization of the polymer and building The rough surface makes the membrane superhydrophobic. Membrane morphology such as figure 1 , Figure 4 and Figure 5 .

Embodiment 2

[0053] Mix 110.6g of dimethylacetamide, 30g of polyvinylidene fluoride, 38.5g of pentylene glycol, 2.0g of water, and 2.7g of kaolin with a particle size of 0.28μm, and cast the film on a glass plate at a temperature of 80°C. membrane.

[0054] The contact angle of the obtained membrane is 135°, and the water flux is 15.79L / m 2 .h, porosity 72%.

Embodiment 3

[0056] Mix 110.6g of dimethylformamide, 30g of polyvinylidene fluoride, 38.5g of propylene glycol, and 0.7g of aluminum oxide with a particle size of 0.24μm and mix evenly. The temperature of the casting solution is 80°C, and the scraped film is cast on a glass plate.

[0057] The resulting membrane has a contact angle of 145° and a water flux of 10.3 L / m 2 .h, porosity 69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com