NiO/ZnO nano-rod based heterojunction diode and preparation method thereof

A nanorod and diode technology, applied in the field of semiconductor photodetection, can solve the problems of high temperature and expensive production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The FTO substrate was submerged in soapy water for several minutes, then ultrasonically treated in acetone, ethanol, and deionized water for 30 minutes, and finally, the FTO substrate was dried at 90ᵒC.

[0022] Dissolve 0.4M zinc acetate in ethylene glycol and stir for 45 minutes. When the solution turns milky white, add a few drops of diethanolamine as a stabilizer until the solution becomes transparent again, then spin-coat the solution and place it on a hot plate Drying on the air for 10 minutes, where the rotation speed was 3000 rpm, and the drying temperature was 300ᵒC, respectively dissolved 0.1M hexamethylphosphoric acid triamide and zinc nitrate in deionized water, and stirred for 1 hour, then the two solutions were mixed, and Stir for 1 hour, immerse the substrate with the seed layer face down in the solution, and heat in the furnace for 3 hours at a heating temperature of 90ᵒC. After the reaction, wash the substrate covered with nanorods with deionized water ...

Embodiment 2

[0025] The FTO substrate was submerged in soapy water for several minutes, then ultrasonically treated in acetone, ethanol, and deionized water for 30 minutes, and finally, the FTO substrate was dried at 90ᵒC.

[0026] With a molar ratio of 1:1, 0.1 solution of monoethanolamine was dissolved in nickel acetate tetrahydrate in methanol, the solution was stirred at 90ᵒC for 5 hours, and the solution was spin-coated on the surface of the substrate on which ZnO nanorods were grown. The rotation speed is 3000rpm, the time is 30 seconds, and then the substrate is dried at 300ᵒC for 10 minutes. Finally, the sample is annealed at 550ᵒC for 2 hours, and the device is completed.

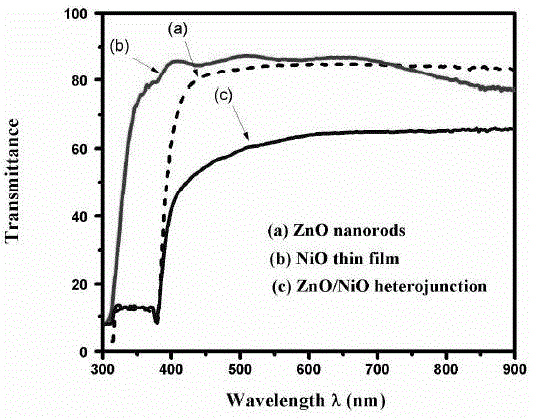

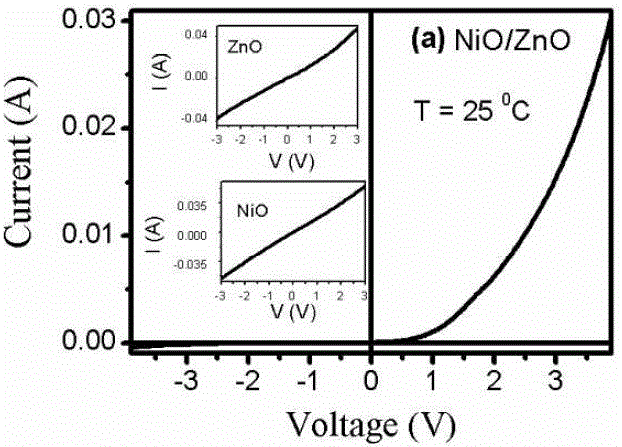

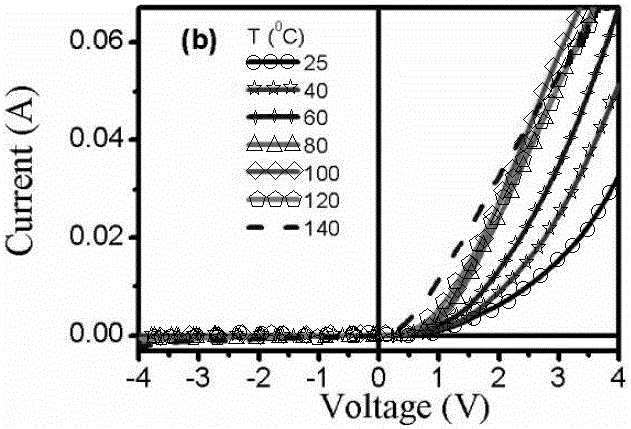

[0027] After the pure nanostructured NiO device was fabricated, it was tested for photoelectric properties, such as figure 1 As shown by the black dotted line in the middle, the light transmission of the device is above 80%, and the absorption edge is around 355nm, as shown in figure 2 , the device forms an o...

Embodiment 3

[0029] The FTO substrate was submerged in soapy water for several minutes, then ultrasonically treated in acetone, ethanol, and deionized water for 30 minutes, and finally, the FTO substrate was dried at 90ᵒC.

[0030] Dissolve 0.4M zinc acetate in ethylene glycol and stir for 45 minutes. When the solution turns milky white, add a few drops of diethanolamine as a stabilizer until the solution becomes transparent again, then spin-coat the solution and place it on a hot plate Drying on the air for 10 minutes, where the rotation speed was 3000 rpm, and the drying temperature was 300ᵒC, respectively dissolved 0.1M hexamethylphosphoric acid triamide and zinc nitrate in deionized water, and stirred for 1 hour, then the two solutions were mixed, and Stir for 1 hour, immerse the substrate with the seed layer face down in the solution, and heat in the furnace for 3 hours at a heating temperature of 90ᵒC. After the reaction, wash the substrate covered with nanorods with deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com