Antibacterial plastic for washing machine and preparation method thereof

A technology of antibacterial plastics and washing machines, which is applied in the field of antibacterial plastics for washing machines and its preparation, which can solve the problems of short duration, easy discoloration, and small antibacterial range, and achieve improved antibacterial and bactericidal capabilities, good anti-ultraviolet aging capabilities, and reduced The effect of decreased antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

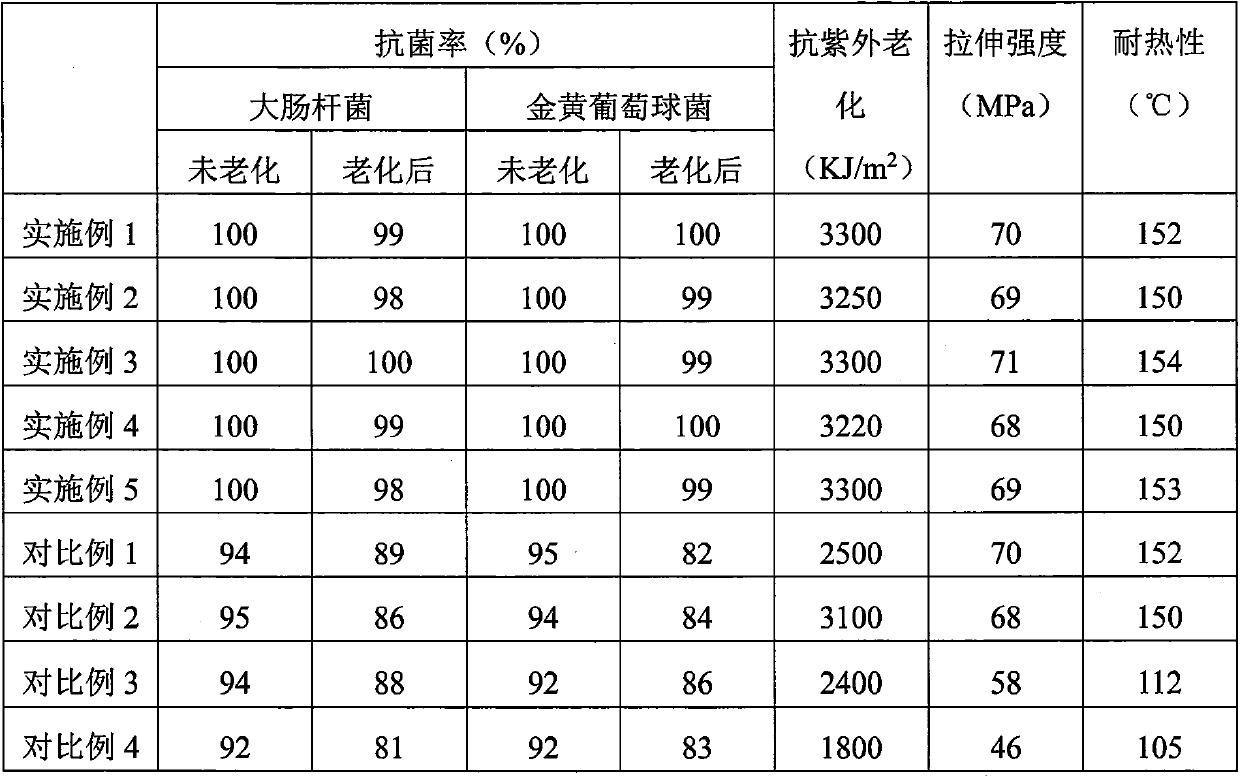

Examples

Embodiment 1

[0021] Prepare antibacterial plastic for washing machine through the following steps:

[0022] (1) Preparation of polymer: 700g acrylonitrile, 300g styrene, 20g vinyl siloxane, 10g sodium 2-acrylamido-2-methylpropanesulfonate, 100g butadiene, 50g vinyl pyridine and 5g of azobisisobutyronitrile was dissolved in 3000g of N,N-dimethylformamide, and the polymerization reaction was carried out under the protection of an inert atmosphere. The reaction temperature was 50°C and the reaction time was 8 hours. After the reaction, it was dissolved, precipitated, washed and Drying to obtain a polymer;

[0023] (2) Polymer ionization: the polymer prepared in step (1) is added to a 20% iodomethane acetonitrile solution, soaked at 50°C for 10 hours, then washed and dried;

[0024] (3) Ion exchange: the polymer obtained in step (2) is added to a 20% sodium benzotriazole aqueous solution, soaked at 50°C for 72 hours, then washed and dried, and then the product is added to the mass Soak in a 20% sil...

Embodiment 2

[0027] Prepare antibacterial plastic for washing machine through the following steps:

[0028] (1) Preparation of polymer: 700g acrylonitrile, 300g styrene, 25g vinyl siloxane, 15g sodium 2-acrylamido-2-methylpropanesulfonate, 120g butadiene, 60g vinyl pyridine and 5g of azobisisobutyronitrile was dissolved in 4000g of dimethyl sulfoxide, and the polymerization reaction was carried out under the protection of an inert atmosphere. The reaction temperature was 70°C and the reaction time was 7 hours. After the reaction, the polymer was obtained by dissolution, precipitation, washing and drying;

[0029] (2) Polymer ionization: Add the polymer prepared in step (1) to a 25% iodoethane acetonitrile solution, soak at 50°C for 10 hours, then wash and dry;

[0030] (3) Ion exchange: Add the polymer obtained in step (2) to a 25% sodium pentachlorophenate aqueous solution, soak at 50°C for 72 hours, then wash and dry, and then add the product to a mass fraction of Soak in 25% silver nitrate aq...

Embodiment 3

[0033] Prepare antibacterial plastic for washing machine through the following steps:

[0034] (1) Preparation of polymer: 700g acrylonitrile, 300g styrene, 27g vinyl siloxane, 16g sodium 2-acrylamido-2-methylpropanesulfonate, 130g butadiene, 70g vinyl pyridine and 5g of azobisisobutyronitrile was dissolved in 4500g of N-methylpyrrolidone, and the polymerization reaction was carried out under the protection of an inert atmosphere. The reaction temperature was 80°C and the reaction time was 6 hours. After the reaction, the polymer was obtained by dissolution, precipitation, washing and drying. ;

[0035] (2) Polymer ionization: The polymer prepared in step (1) is added to a 28% mass fraction of 1-iodopropane acetonitrile solution, soaked at 50°C for 10 hours, then washed and dried;

[0036] (3) Ion exchange: add the polymer obtained in step (2) to a 27% sodium diacetate aqueous solution, soak at 50°C for 72 hours, then wash and dry, and then add the product to a mass fraction of 28 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com