Magnetic solid polyamino adsorbent granular material, preparation method and application thereof

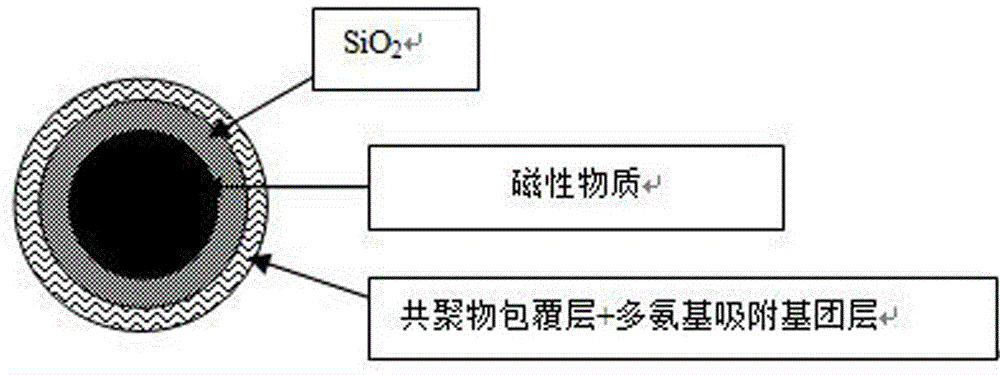

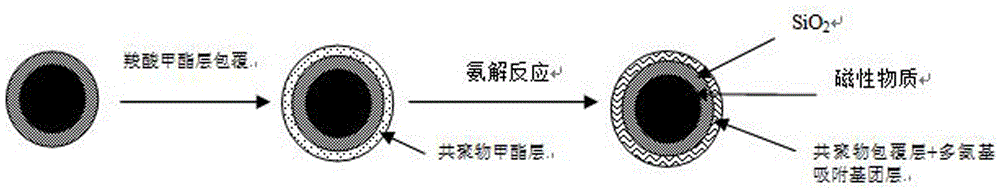

A granular material and polyamino technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of limited application range, organic coating layer or amino group is easy to fall off, and ferric oxide is resistant to oxidation and acid resistance are not strong, etc., to achieve the effect of low treatment cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

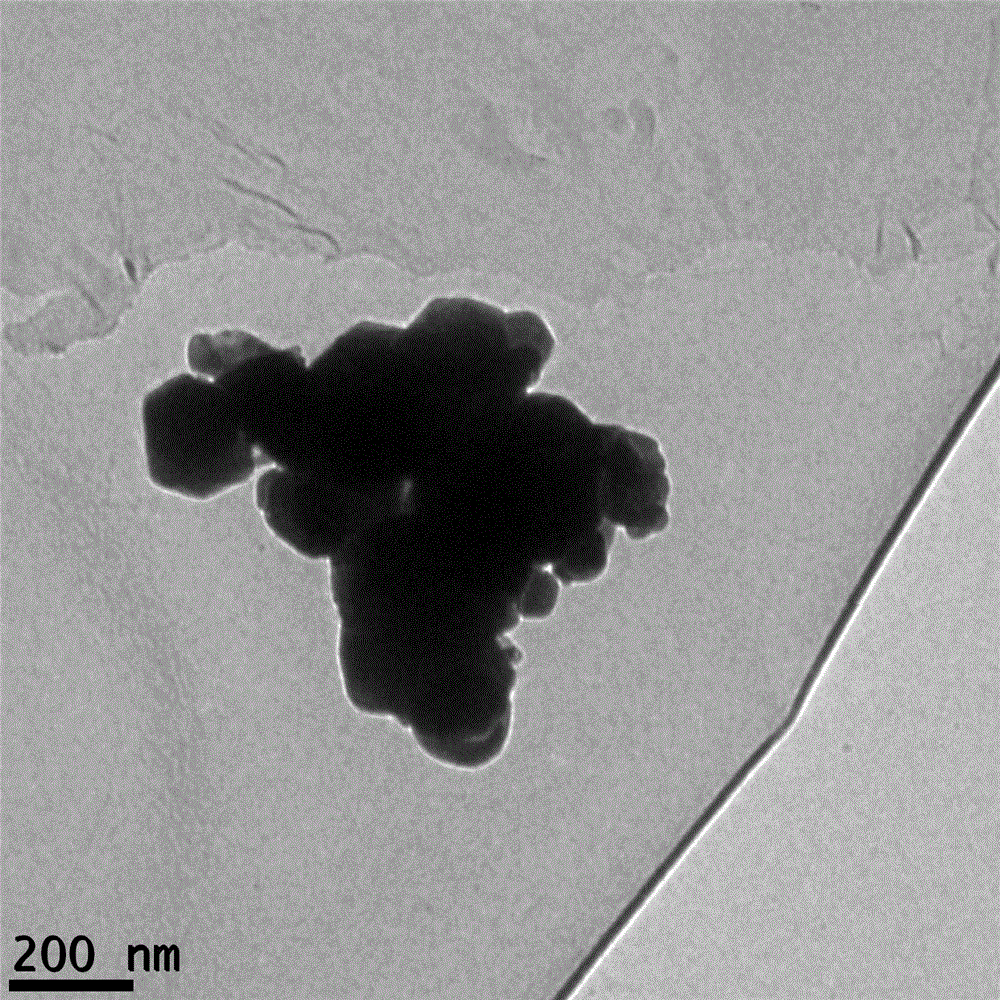

[0065] A kind of magnetic polyamino granular material, when polyamino adsorption group wherein is from polyallylamine (hydrochloride) that degree of polymerization is 30, its preparation method is described as follows:

[0066] 40g of Fe with an average particle size of 0.02μm 3 o 4 Magnetic powder, 40g tetraethyl orthosilicate, mixed with 300ml absolute ethanol, add dropwise a mixture of 40ml ammonia water and 20ml ethanol at 20°C for 1 hour, then react at 70°C for 10h, filter, wash with ethanol, and dry at 110°C Get FS.

[0067] Take 40gFS, 20g vinyltriethyl (m)oxysilane, mix 100ml ethanol, 3ml ammonia water, stir at 50°C for 10h, make it silanized on the surface of the substrate, then use a magnet to separate the granular material, wash with ethanol, 60 ℃ drying, the magnetic powder material FS@- double bond coated with carbon-carbon double bond on the surface is obtained.

[0068] Take 40g FS@- double bond, 80g methyl methacrylate, 400ml water, 2g benzoyl peroxide...

Embodiment 2

[0073] A magnetic polyamino granular material, when the polyamino adsorption group wherein is from diethylenetriamine, its preparation method is described as follows:

[0074] Mix 40g of ferric iron tetroxide powder with an average particle size of 0.20μm (content greater than 99%), 10g of tetraethyl orthosilicate, and 300ml of absolute ethanol, and add dropwise a mixture of 40ml of ammonia water and 20ml of ethanol at 20°C for 1 hour , and then reacted at 70°C for 10h, filtered, washed with ethanol, and dried at 110°C to obtain FS.

[0075] Mix 40gFS, 20g vinyltrichlorosilane, 200ml ethanol, 3ml ammonia water, stir at 55°C for 8h to cause silanization reaction on the surface of the substrate, then use a magnet to separate the granular material, wash with ethanol, and dry at 60°C to obtain Magnetic powder material FS@-double bond coated with carbon-carbon double bond on the surface.

[0076] Take 40g of FS@- double bond, 60g of methyl methacrylate and 20g of glycidyl me...

Embodiment 3

[0081] A kind of magnetic polyamino particle material, when polyamino adsorption group wherein is from the degradation product of chitosan, its preparation method is described as follows:

[0082] Mix 40g of magnetite powder with an average particle size of 50.0μm (content greater than 90%), 10g of tetraethyl orthosilicate, and 300ml of absolute ethanol, and add a mixture of 40ml of ammonia water and 20ml of ethanol dropwise at 20°C for 1 hour. Then react at 70°C for 10h, filter, wash with ethanol, and dry at 110°C to obtain FS.

[0083] Take 40gFS, 20g γ-(methacryloyloxy)propyltrimethoxysilane, 200ml toluene, mix them with 3ml ammonia water, stir at 55°C for 8 hours to make silanization reaction occur on the surface of the substrate, and then use a magnet to separate the granular material, After washing with ethanol and drying at 60°C, the magnetic powder material FS@- double bond coated with carbon-carbon double bond was obtained.

[0084] Take 40g of FS@- double bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com