Production method for granular function-intensifying type magnesium-containing ammonium phosphate

A technology of magnesium-containing ammonium phosphate and production method, applied in ammonium orthophosphate fertilizer, magnesium fertilizer, phosphate fertilizer and other directions, can solve the problems of dust pollution, existing environment and crops, difficulty in adding sulfur, etc., to promote absorption and utilization, and improve crop quality. , the effect of improving the utilization rate of phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

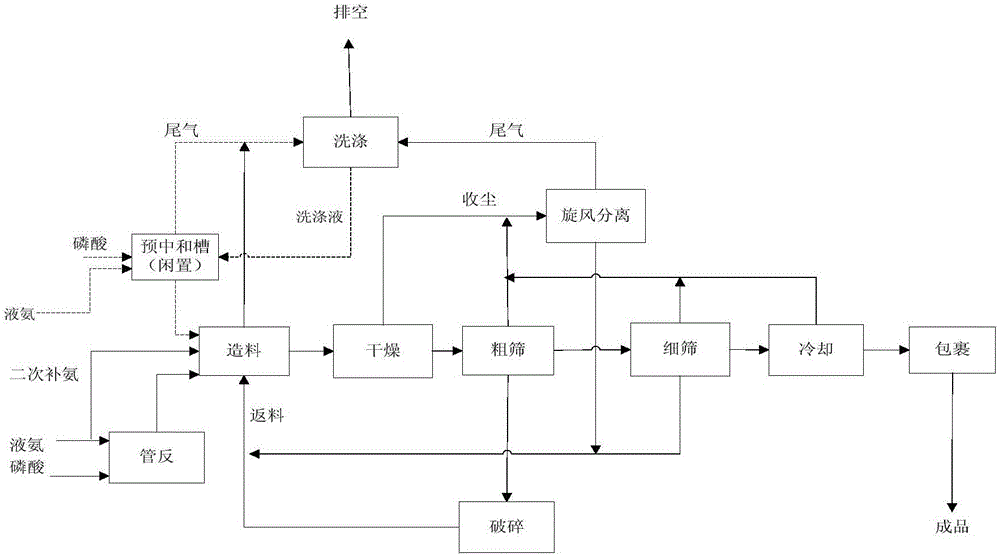

Image

Examples

Embodiment 1

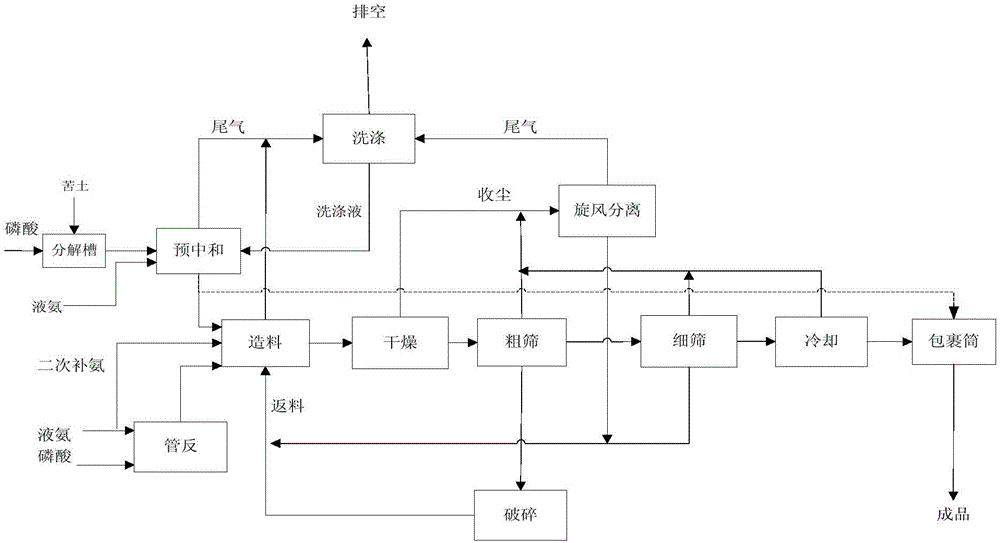

[0034] Preparation of granular, functionally enhanced magnesium-containing ammonium phosphate products, specifically as figure 2 shown.

[0035] (1) The total amount of phosphoric acid used to produce ammonium phosphate products is 100 parts (in terms of pure P 2 o 5 Calculated, the same below), take out 20 parts and send them to the newly added reaction tank, add pure MgO accounting for 25% of the required theoretical dosage based on the complete generation of magnesium ammonium phosphate, stir and mix evenly, control the reaction temperature at 50°C, and pass 40min The reaction was stirred to obtain reactant A containing magnesium dihydrogen phosphate solution. In this embodiment, the MgO content of the actual bitter soil used is 75%, so the actual amount of the physical bitter soil added is 3.8 parts.

[0036] Calculation instructions for adding quantity of bitter soil: according to H 3 PO 4 With MgO, NH 3 Complete reaction to generate MgNH 4 PO 4 The chemical reac...

Embodiment 2

[0042] (1) The total amount of phosphoric acid used to produce ammonium phosphate products is 100 parts (in terms of pure P 2 o 5 Calculated, the same below), take out 10 parts and send them to the newly added reaction tank, add pure MgO, which accounts for 15% of the required theoretical dosage, calculated based on the complete generation of magnesium ammonium phosphate, stir and mix evenly, control the reaction temperature at 40°C, and pass 45min Reaction, obtains reactant A containing magnesium dihydrogen phosphate solution. In this embodiment, the MgO content of the actual bitter soil used is 80%, so the actual amount of the physical bitter soil added is 1.1 parts.

[0043] (2) Reactant A is sent into the existing pre-neutralization tank of the ammonium phosphate production unit, feeds liquid ammonia, and is neutralized to the normal control neutralization degree of ammonium phosphate production (neutralization degree is the molar ratio of nitrogen to phosphorus: phosphor...

Embodiment 3

[0048] (1) The total amount of phosphoric acid used to produce ammonium phosphate products is 100 parts (in terms of pure P 2 o 5 Calculated, the same below), take out 10 parts and send them to the newly added reaction tank, add pure MgO accounting for 25% of the required theoretical dosage based on the complete generation of magnesium ammonium phosphate, stir and mix evenly, control the reaction temperature at 50°C, and pass 60min Reaction, obtains reactant A containing magnesium dihydrogen phosphate solution. In this embodiment, the MgO content of the actual bitter soil used is 85%, so the actual amount of the physical bitter soil added is 1.7 parts.

[0049] (2) Reactant A is sent into the existing pre-neutralization tank of the ammonium phosphate production unit, feeds liquid ammonia, and is neutralized to the normal control neutralization degree of ammonium phosphate production (neutralization degree is the molar ratio of nitrogen to phosphorus: phosphoric acid Monoammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com