Aluminum-magnesium alloy structural component additive manufacturing method

An aluminum-magnesium alloy and additive manufacturing technology, which is applied to manufacturing tools, metal processing equipment, arc welding equipment, etc., can solve problems such as large residual stress, unclean cleaning, and spheroidization, so as to save magnesium-aluminum alloy materials and improve Effect of average tensile strength and enhanced bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

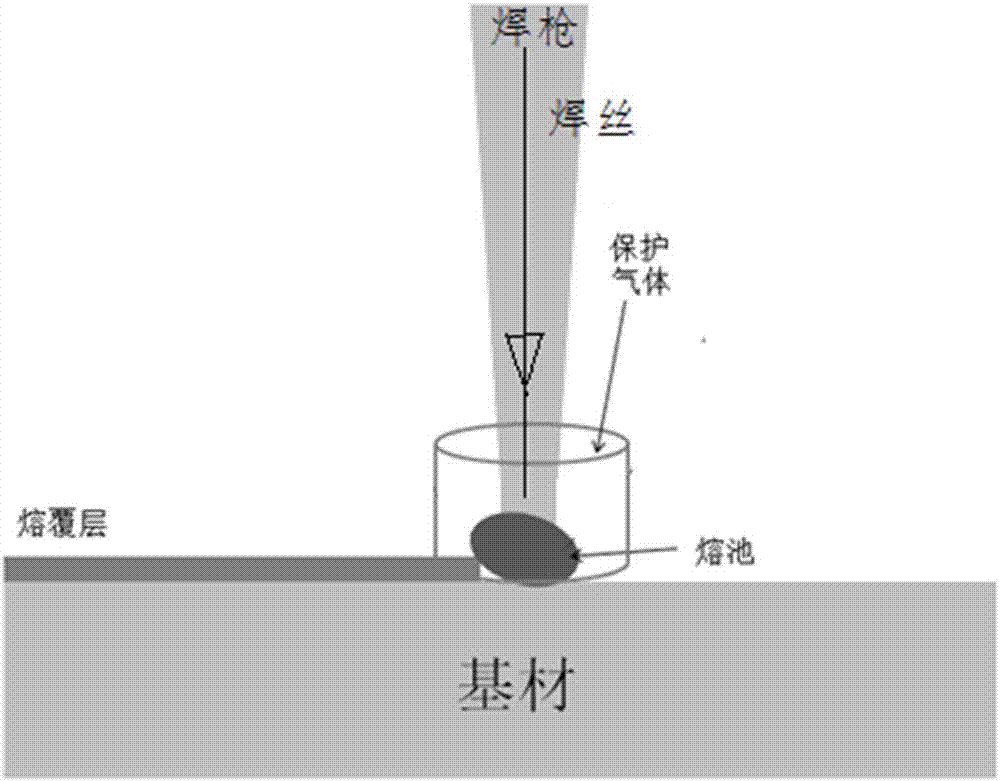

[0028] A method for additive manufacturing of aluminum-magnesium alloy structural parts, specifically comprising the following steps:

[0029] (1) Substrate pretreatment: Firstly, the aluminum alloy substrate material is ground and polished with sandpaper, and then, at a temperature of 40° C., a hydrofluoric acid solution with a concentration of 3% and a sulfuric acid solution with a concentration of 8% are used in a mass ratio of 1 : Wash with acid solution composed of 3 for 20-30 minutes, then wash with water, then put it into acetone, ethanol and ultrapure water for 5-10 minutes to ultrasonically clean it in order to remove surface impurities, take it out and dry it, and use laser marking machine to process the surface microstructure to form a truss-shaped microstructure with a pitch of 50 μm, ready for use;

[0030] (2) Preparation of aluminum-magnesium alloy wire: 1. the mass fraction is 8% of pure magnesium ingot, 70% of aluminum powder, and 22% of iron-based alloy powde...

Embodiment 2

[0035] A method for additive manufacturing of aluminum-magnesium alloy structural parts, specifically comprising the following steps:

[0036] (1) Substrate pretreatment: Firstly, the aluminum alloy substrate material is ground and polished with sandpaper, and then, at a temperature of 30° C., with a hydrofluoric acid solution with a concentration of 3% and a sulfuric acid solution with a concentration of 8% in a mass ratio of 1 : Wash with acid solution composed of 3 for 20-30 minutes, then wash with water, then put it into acetone, ethanol and ultrapure water for 5-10 minutes to ultrasonically clean it in order to remove surface impurities, take it out and dry it, and use laser marking The surface microstructure is processed by a machine to form a truss-shaped microstructure with a spacing of 100 μm, which is ready for use;

[0037] (2) Preparation of aluminum-magnesium alloy wire: 1. the mass fraction is 5% of pure magnesium ingot, 65% of aluminum powder, and 30% of iron-ba...

Embodiment 3

[0042] A method for additive manufacturing of aluminum-magnesium alloy structural parts, specifically comprising the following steps:

[0043] (1) Substrate pretreatment: Firstly, the aluminum alloy substrate material is ground and polished with sandpaper, and then, at a temperature of 50° C., use a hydrofluoric acid solution with a concentration of 3% and a sulfuric acid solution with a concentration of 8% in a mass ratio of 1 : Wash with acid solution composed of 3 for 20-30 minutes, then wash with water, then put it into acetone, ethanol and ultrapure water for 5-10 minutes to ultrasonically clean it in order to remove surface impurities, take it out and dry it, and use laser marking machine to process the surface microstructure to form a truss-shaped microstructure with a pitch of 200 μm, ready for use;

[0044] (2) Preparation of aluminum-magnesium alloy wire: 1. the mass fraction is 10% of pure magnesium ingot, 75% of aluminum powder, and 15% of iron-based alloy powder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com